31bb3

Landlord.

cor brew porn :mrgreen:

Vossy1 said:Nice work up :clap: what size holes did you go for and what flow rate :hmm:

Open tun drain, start pump, get steady spinning, shut tun drain, count 1 min, stop pump, water in tun = flow rate.Flowrate no flow meter so ? GP550 with throttle valve just open and balance valve fully open & it spins as in the video attached

unclepumble said:I have done bugger all with the brewery for a while so New Years day New years resolution "Pull my finger out"

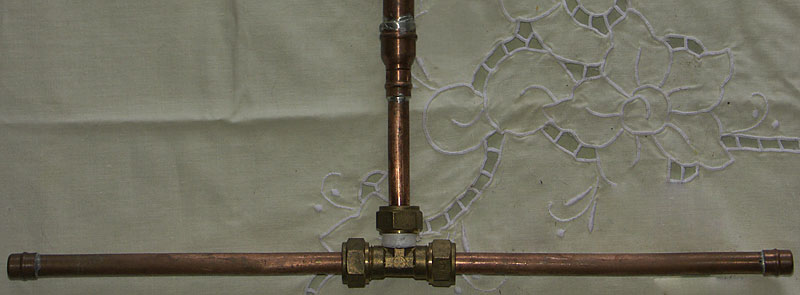

Made a spinning sparge arm out of copper etc.. and gave it a little whirl this afternoon.

http://www.youtube.com/user/UNCLEPUMBLE ... ntVJ648MPk

UP

unclepumble said:Lube not advised it will leach at 70odd deg better to wind a couple of turns of PTFE round the olive PTFE IS VERY LOW FRICTION. the other thing I did was ensure the olive was tightened near the end of the pipe, IE pipe not fully home when olive nipped up. And about 50 turns of PTFE round the threads.

Aleman said:unclepumble said:Lube not advised it will leach at 70odd deg better to wind a couple of turns of PTFE round the olive PTFE IS VERY LOW FRICTION. the other thing I did was ensure the olive was tightened near the end of the pipe, IE pipe not fully home when olive nipped up. And about 50 turns of PTFE round the threads.

Like This

Really spins a bit easier now thanks Shane :thumb: