You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help Support The Homebrew Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

You don't need temperature control to make a lager - a cool spot, a crate of water, regularly change ice blocks and choose the right yeast.OK, thanks, that's no good then. No worries, I have plenty of other options!

W-34/70 if you want dry, WY2124 if you want liquid. Both are very widely used and will make good lager even at higher temperatures

I did enjoy drinking my first attempt at Phoney Peroni last year and so today I brewed it again with only a very minor change in that I included 5% wheat malt to give it a bit more of a sticky head.

The flaked, torrefied maize has already been cooked to gelatinise it so it goes straight into the mash without the need for grinding or pre-cooking.

The stickiness of the corn is evident in the thick clumps you can see in the spent grain. Mindful of falling short on the mash extraction last time I had a bag of dextrose ready in case the same happened again this time. I was only point short of the expected pre-boil gravity this time so I added 77g of dextrose into the boil to bump it up a point. I also used 30g instead of 25g of Saaz at 5 minutes to use up the last of the pack that I had. I don't think you can overdo noble hops.

Everything else about the brew day was completely normal and I collected around 23.5 litres of 1.046 wort.

The wort was extremely pale as expected. I got it down to about 23C with the immersion chiller in half and hour and it's now coming down the rest of the way to the pitching temperature of 13.5C in the brew fridge.

The 3.2 litre Wyeast 2352-PC starter was all finished on Friday morning and I successfully removed 500ml to keep in the fridge for the next lager. This is a very flocculent yeast so I'll have no trouble decanting most of the spent wort when it comes to pitching time which should be tomorrow morning.

Code:

Recipe Specifications

--------------------------

Recipe: Phoney Peroni

Batch Size (fermenter): 24.00 L

Estimated OG: 1.047 SG

Estimated Color: 6.1 EBC

Estimated IBU: 29.6 IBUs

Brewhouse Efficiency: 75.00 %

Est Mash Efficiency: 75.6 %

Boil Time: 60 Minutes

Finished water profile: Ca:28, Mg:3, Na:9, SO4:10, Cl:44

Ingredients:

------------

Amt Name Type %/IBU Volume

3.70 ml Lactic Acid (Mash) Water Agent 80% -

1.20 g Calcium Chloride (Mash) Water Agent - -

3.60 kg Weyermann Bohemian Pilsner (4.0 EBC) Grain 74.2 % 2.35 L

1.00 kg Crisp Flaked Torrefied Maize (1.3 EBC) Grain 20.6 % 0.65 L

0.25 kg Weyermann Wheat Malt (3.9 EBC) Grain 5.2 % 0.16 L

0.30 g Calcium Chloride (Sparge) Water Agent - -

0.20 ml Lactic Acid (Sparge) Water Agent 80% -

18.00 g Hallertau Magnum [10.70 %] - Boil 60.0 min Hop 21.5 IBUs -

10.00 g Saaz [4.70 %] - Boil 15.0 min Hop 2.6 IBUs -

15.00 g Saaz [4.70 %] - Boil 10.0 min Hop 2.9 IBUs -

1.00 Items Whirlfloc Tablet (Boil 7.0 mins) Fining - -

25.00 g Saaz [4.70 %] - Boil 5.0 min Hop 2.6 IBUs -

1.0 pkg Munich Lager II (Wyeast Labs #2352-PC) Yeast - -

Mash Schedule: Single Infusion, Medium Body, Batch Sparge

Total Grain Weight: 4.85 kg

----------------------------

Name Description Step Temperat Step Time

Mash In Add 24.55 L of water at 70.9 C 65.0 C 60 min

Sparge: Dunk sparge with 5L of 75C water.The flaked, torrefied maize has already been cooked to gelatinise it so it goes straight into the mash without the need for grinding or pre-cooking.

The stickiness of the corn is evident in the thick clumps you can see in the spent grain. Mindful of falling short on the mash extraction last time I had a bag of dextrose ready in case the same happened again this time. I was only point short of the expected pre-boil gravity this time so I added 77g of dextrose into the boil to bump it up a point. I also used 30g instead of 25g of Saaz at 5 minutes to use up the last of the pack that I had. I don't think you can overdo noble hops.

Everything else about the brew day was completely normal and I collected around 23.5 litres of 1.046 wort.

The wort was extremely pale as expected. I got it down to about 23C with the immersion chiller in half and hour and it's now coming down the rest of the way to the pitching temperature of 13.5C in the brew fridge.

The 3.2 litre Wyeast 2352-PC starter was all finished on Friday morning and I successfully removed 500ml to keep in the fridge for the next lager. This is a very flocculent yeast so I'll have no trouble decanting most of the spent wort when it comes to pitching time which should be tomorrow morning.

- Joined

- Mar 6, 2019

- Messages

- 8,165

- Reaction score

- 11,309

Any update on the Munich dunkel

Still conditioning in the keezer (2 weeks so far). I think I'll start it in another 2 weeks.Any update on the Munich dunkel

£437.77

HMCOCOOFM 4L 4" OD119mm * 1.5" OD50.5mm Copper Onion Head For Homebrewing,Thickness 1.5mm (With Thermometer)

weifangguanhuawangluokejiyouxiangongsi

£73.98

Sanitary clamp 2" (51mm) OD64mm Sanitary Tri-Clamp 90-Degree Pipe With Nipple And Electronic Thermometer, Stainless Steel 304 Home brewing(Without Thermometer)

DAN CHENG XIAN PENG SHI DA SHANG MAO DIAN

£13.79

£18.99

New Brewing Lager Beer: The Most Comprehensive Book for Home and Microbrewers

Amazon.co.uk

£14.76

Digital Temperature Watch Heating Thermometer Home Brewing Tools for Wine Bottle

B&D DIRECT STORE

£6.59 (£235.36 / kg)

2X Bulldog Mead Yeast & Nutrient High Alcohol 28g for 20-25L

Virtuoso (VAT Registered)

£5.42 (£0.02 / 100 ml)

Elderflower Sparkling Wine Yeast 5-25L Homebrew Wine, Mead, Cider, Ginger Beer

247 Homebrew

£19.23

£22.00

The Big Book of Kombucha: Brewing, Flavoring, and Enjoying the Health Benefits of Fermented Tea

Amazon US

£62.70

Cider Making Kit - with Bottles - 10L/2 Gallon/20 Pints Home Brew Beer Ale Lager

247 Homebrew

£23.75 (£25.45 / 75 cl)

Kinsale Mead Co. Atlantic Dry Mead 70cl, Light, Off Dry, Refreshingly Different Award-Winning Honey Mead, 12% ABV

Amazon.co.uk

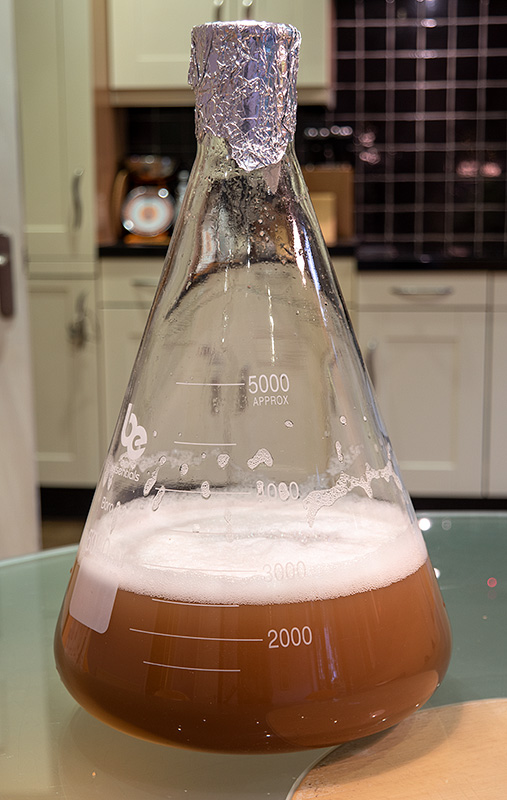

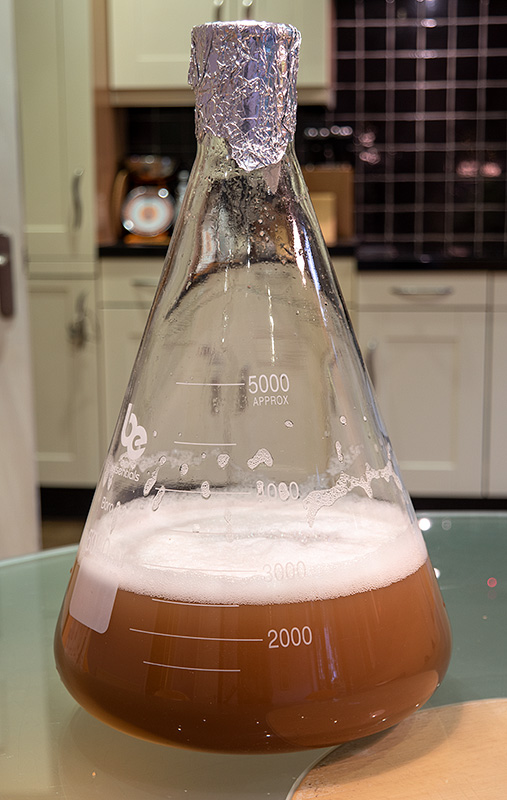

The Phoney Peroni fermentation has started well. I pitched the decanted 2.7 litre starter of Wyeast 2352-PC at 8:00am on Monday morning at 13.5C and 14 hours later it had started bubbling through the blow-off tube. That could be one of the fastest starts I've seen to a cold lager fermentation. I'm usually used to waiting 18-24 hours for any visible action when fermenting cold. Re-used yeast from an overbuilt starter always seems to me to be more eager to get going and this is beer #3 from this pack of yeast.

BeerCat

Landlord.

- Joined

- May 6, 2015

- Messages

- 5,292

- Reaction score

- 1,694

I love a corn lager. Have a similar beer to package this week. Lost count what generation I am at with the yeast but it's over 2 years now and going strong. Being lazy i got fed up preparing starters and now I prefer to keg and immediately use the whole cake in the next batch.

I kegged the Phoney Peroni yesterday afternoon after 3 weeks in the fermenter. It had about 5 days at 13.5C then the rest of the time at 17C to finish and clear up.

FG was 1.005, more-or-less the same as the first time I brewed this and the ABV will be 5.4%.

The sample was nice and clear, and of course as pale as they come for a lager. I got a keg and 3 bottles from the left overs. The keg was fined with Clear-It, purged at 5x15psi and is sitting there at 20psi and 6.5C for the carbing and conditioning. Hopefully we'll get some nice days in July and August when I can enjoy drinking this outside in the sun.

FG was 1.005, more-or-less the same as the first time I brewed this and the ABV will be 5.4%.

The sample was nice and clear, and of course as pale as they come for a lager. I got a keg and 3 bottles from the left overs. The keg was fined with Clear-It, purged at 5x15psi and is sitting there at 20psi and 6.5C for the carbing and conditioning. Hopefully we'll get some nice days in July and August when I can enjoy drinking this outside in the sun.

BeerCat

Landlord.

- Joined

- May 6, 2015

- Messages

- 5,292

- Reaction score

- 1,694

@BeerCat do you have a favourite recipe for your corn lagers?

Yes here you go.

OG 1040

FG 1004

ABV 4.7%

SRM 2.7

IBU 18

German pilsner 80.3%

flaked maize 16.7%

acid malt 3%

mash ph 5.2

mash at 62c for 120 minutes

mashout at 75c for 10m

I like to use crisp german pilsner or bohemian and aim for around 14 IBU's with first wort hops. Saaz or magnum and another 4 IBU's at 15 minutes of mittlefruh.

Start the fermentation cold and let it chug along at 9c for about 8 to 10 days then i ramp it up 1 or 2c a day until i hit 18c. I leave it until day 21 then cold crash to zero for 1 week. Add isinglass halfway through the week, keg and force carb.

I use RO water with 3 grams of calcium chloride in the mash and I don't treat the sparge water.

For yeast i like wyeast 2278 czech pils, wyeast Mexican lager and i really like mangrove jacks bohemian as well.

That's more or less a Helles with added corn. I bet it's very smooth and easy drinking. I've run out of flaked maize at the moment but I'll put something like this on the list to brew next time I'm ordering a batch of grains.Yes here you go.

OG 1040

FG 1004

ABV 4.7%

SRM 2.7

IBU 18

German pilsner 80.3%

flaked maize 16.7%

acid malt 3%

mash ph 5.2

mash at 62c for 120 minutes

mashout at 75c for 10m

I like to use crisp german pilsner or bohemian and aim for around 14 IBU's with first wort hops. Saaz or magnum and another 4 IBU's at 15 minutes of mittlefruh.

Start the fermentation cold and let it chug along at 9c for about 8 to 10 days then i ramp it up 1 or 2c a day until i hit 18c. I leave it until day 21 then cold crash to zero for 1 week. Add isinglass halfway through the week, keg and force carb.

I use RO water with 3 grams of calcium chloride in the mash and I don't treat the sparge water.

For yeast i like wyeast 2278 czech pils, wyeast Mexican lager and i really like mangrove jacks bohemian as well.

I used 2278 two years back in a Czech Pils and liked it a lot. I found it very clean and quite similar in character to the 2352 that I'm on a bit of a roll with at the moment.

Hey @foxbat - old post I know (a year and a day actually!) so maybe your closed transfer technique has evolved further since then.....I've made another improvement to my process in the name of further reducing post-fermentation oxygen exposure. I already transfer directly from the valve on my fermenter to a corny keg and then purge the head space with CO2 before leaving under pressure to carbonate.

Now I've decided to use the CO2 generated during fermentation to purge a corny keg so that I can transfer directly into a CO2-rich atmosphere before sealing up the keg. What made me decide that it was worth it was this post by HBT's resident mad scientist doug293cz. Here's what I did.

Previously I would use a blowoff tube inside the brew fridge. That is, a barb on the top of the fermenter has a short length of 3/8" beer line leading to a jam jar containing star-san to use as the bubbler air lock.

Now I'm running a longer length of 3/8" line from the fermenter barb, down through the fridge drain plug at the back and out to the gas-in line of a sanitised keg. The beer-out line now goes to the jam jar bubbler to complete the system.

In the above picture you can see the tube going down the drain plug. My fridge is a cheap Curry's brand undercounter model. The drain plug was lined with the tube that you can see on the left. To get it out I jammed a circular file into it which gripped it from within. It was easy then to yank upwards to remove it. Luckily the drain plug hole is exactly 3/8" diameter and the tube pushes firmly through.

This image shows the complete picture. You can see the 3/8" tube snaking out from the back of the fridge to the keg disconnect on the left and then the other keg disconnect is directed upwards into the sanitiser-filled jam jar that's been lashed into place with a few elastic bands that our litter-lout postman kindly drops all over the pavement on our street.

So that's it then, a simple process improvement using bits and pieces that I already had that hopefully will preserve those hop flavours a bit better.

I get the basic idea what's going on in closed transfer from what you've said, other posts on the web and YouTube videos.....

Out of interest have you tried using the CO2 produced during fermentation to displace Starsan from your corny keg or are you still doing it as described above with CO2 going through the keg and then into a jam jar of Starsan?

And when you transfer I get that you have a tap on your FVs - are you also supplying low pressure CO2 into the top of your FV (through the airlock hole?) to help push out the beer and take up the volume left as the beer leaves the FV?

Or are you simply allowing air to be pulled in through the lid? (Not strictly closed in that case I suppose)

No tap on my FVs so I would either have to add one, or make another hole in the lid to insert a dip tube while pumping gas in through the airlock hole.

I'm still doing it by purging the air rather than pushing out starsan. Doug on HBT worked out that would get you down to 5ppb O2 in the keg after a typical fermentation which was definitely low enough for me! The Starsan method would need pressure to displace it and when I contacted Brewbuilder about doing pressure fermentation in my FV the answer was an unequivocal "no". Then there's the issue of having another free vessel to collect the Starsan. Nah, too much effort. I'm all for removing steps from my procedure where I can rather than adding new ones.Hey @foxbatOut of interest have you tried using the CO2 produced during fermentation to displace Starsan from your corny keg or are you still doing it as described above with CO2 going through the keg and then into a jam jar of Starsan?

No, I just loosen the tri-clamp fitting on the port fitted to the lid and air gets drawn in. This doesn't bother me, filling the keg takes only a few minutes and the beer near the surface of the FV will go into the left over bottles anyway.And when you transfer I get that you have a tap on your FVs - are you also supplying low pressure CO2 into the top of your FV (through the airlock hole?) to help push out the beer and take up the volume left as the beer leaves the FV?

Or are you simply allowing air to be pulled in through the lid? (Not strictly closed in that case I suppose)

I would imagine that a tap you can fix a hose to would be easier to handle than trying to keep a dip tube where it should be, rather than where it inevitably will want to be, while also bottling/kegging at the same time.No tap on my FVs so I would either have to add one, or make another hole in the lid to insert a dip tube while pumping gas in through the airlock hole.

Talking of kegging, are you there yet?

Can neither confirm nor deny but might have some news in my brew day thread soonTalking of kegging, are you there yet?

I'm about 3 weeks into my Dunkel that I brewed from Weyermann's recipe and I'm rather pleased with the outcome:

It pours with a slightly tan head that lingers for the full pint. Taste is very much of caramel with a hint of lemon from the Hersbucker hops. If it wasn't served cold then I suspect that the caramel would be too much for many people. I like this a lot and it's one of the few beers where I've thought 'I want to brew this again immediately'. Next time I think I'd do it with a big slug of Saaz because I think the spiciness would complement the caramel really well.

It pours with a slightly tan head that lingers for the full pint. Taste is very much of caramel with a hint of lemon from the Hersbucker hops. If it wasn't served cold then I suspect that the caramel would be too much for many people. I like this a lot and it's one of the few beers where I've thought 'I want to brew this again immediately'. Next time I think I'd do it with a big slug of Saaz because I think the spiciness would complement the caramel really well.

Fine looking pint. I 100% agree on the caramel which was also the case with the GH recipe; I might tweak the grain bill another time. Saaz is a great shout…A Dunkel is on my brew list for this summer after getting on top of stocks. Yours looks fabulous as always!

I've got a brewday planned for this Sunday so today's the day to get the yeast starter on. This'll be the fourth outing for the Wyeast 2352-PC Munich II yeast and the overbuilt starter that I kept in the fridge is looking very clear:

I decanted off most of that starter beer and tasted some of it which was OK; plain and bland like it ought to be. Since this brew will be another lager I made up a 2.5 litre starter of which 500ml will go back in the fridge for next time.

That's now in the brew fridge at 20C for a couple of days until it's completely done and ready to separate off the overbuild.

I decanted off most of that starter beer and tasted some of it which was OK; plain and bland like it ought to be. Since this brew will be another lager I made up a 2.5 litre starter of which 500ml will go back in the fridge for next time.

That's now in the brew fridge at 20C for a couple of days until it's completely done and ready to separate off the overbuild.

Similar threads

- Replies

- 4

- Views

- 579