unclepumble

Landlord.

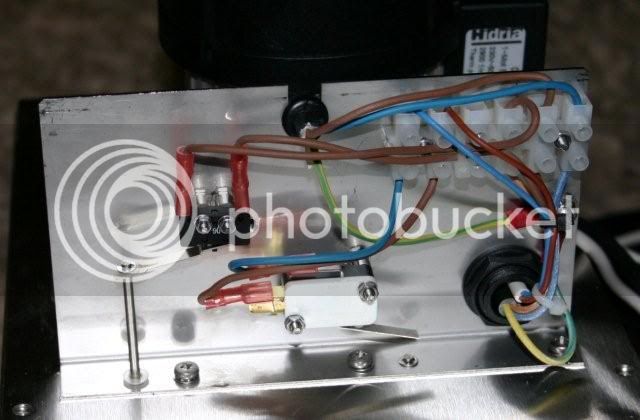

I am just in the planning stages of a 150ltr, 3 possibly 4 vessel set up, (will add some pictures later today)

I currently have 3 150/180 Ltr stainless vessels with slightly conical bottoms & 3" outlets, (bunged up) I have been looking for a some suitable pumps for a few weeks, but want to spend as little as possible (I'm Tight), the 3 vessels only cost me £72.00 each as they were scrapping them where I work. They are ex tuchenhagen dosing pots, and have been used for tetralone, lucilite and isomerised hop extract etc. and as an added bonus all 3 have a small sprayball fitted so think i need to think up a cip set up for them, have been looking at a stuart turner pump for this.

I have been wondering whether to use an underback on the mash vessel, so as to control wort drain off and sparging better, & saw a March May HC1 Condensate pump on fleabay,( http://www.marchmay.co.uk/may06/HC.pdf" onclick="window.open(this.href);return false; ) it has a s/s tank 316 stainless pump shaft, and it states will pump boiling liquid, has anyone tried one of these yet, I thought it was a bargain at £55.00 so have taken the plunge.

I am also looking at copper braised 40-60 plate heat exchangers, (can anyone tell me whats the best cleaning/sanitising solution for these).

Will possibly be picking up a 150-200ltr water jacketed s/s vessel (similar to a thermopocket but on wheels & with a PID control panel pump control etc, part of a depositor system for sauces ex food factory)

I am looking to use 1 pot as HLT, one as a MLT, and one as a copper, however if I get the jacketed vessel then maybe 1 pot could become a fermenter.

Just got to wait for my camera batterys to charge now!

I currently have 3 150/180 Ltr stainless vessels with slightly conical bottoms & 3" outlets, (bunged up) I have been looking for a some suitable pumps for a few weeks, but want to spend as little as possible (I'm Tight), the 3 vessels only cost me £72.00 each as they were scrapping them where I work. They are ex tuchenhagen dosing pots, and have been used for tetralone, lucilite and isomerised hop extract etc. and as an added bonus all 3 have a small sprayball fitted so think i need to think up a cip set up for them, have been looking at a stuart turner pump for this.

I have been wondering whether to use an underback on the mash vessel, so as to control wort drain off and sparging better, & saw a March May HC1 Condensate pump on fleabay,( http://www.marchmay.co.uk/may06/HC.pdf" onclick="window.open(this.href);return false; ) it has a s/s tank 316 stainless pump shaft, and it states will pump boiling liquid, has anyone tried one of these yet, I thought it was a bargain at £55.00 so have taken the plunge.

I am also looking at copper braised 40-60 plate heat exchangers, (can anyone tell me whats the best cleaning/sanitising solution for these).

Will possibly be picking up a 150-200ltr water jacketed s/s vessel (similar to a thermopocket but on wheels & with a PID control panel pump control etc, part of a depositor system for sauces ex food factory)

I am looking to use 1 pot as HLT, one as a MLT, and one as a copper, however if I get the jacketed vessel then maybe 1 pot could become a fermenter.

Just got to wait for my camera batterys to charge now!