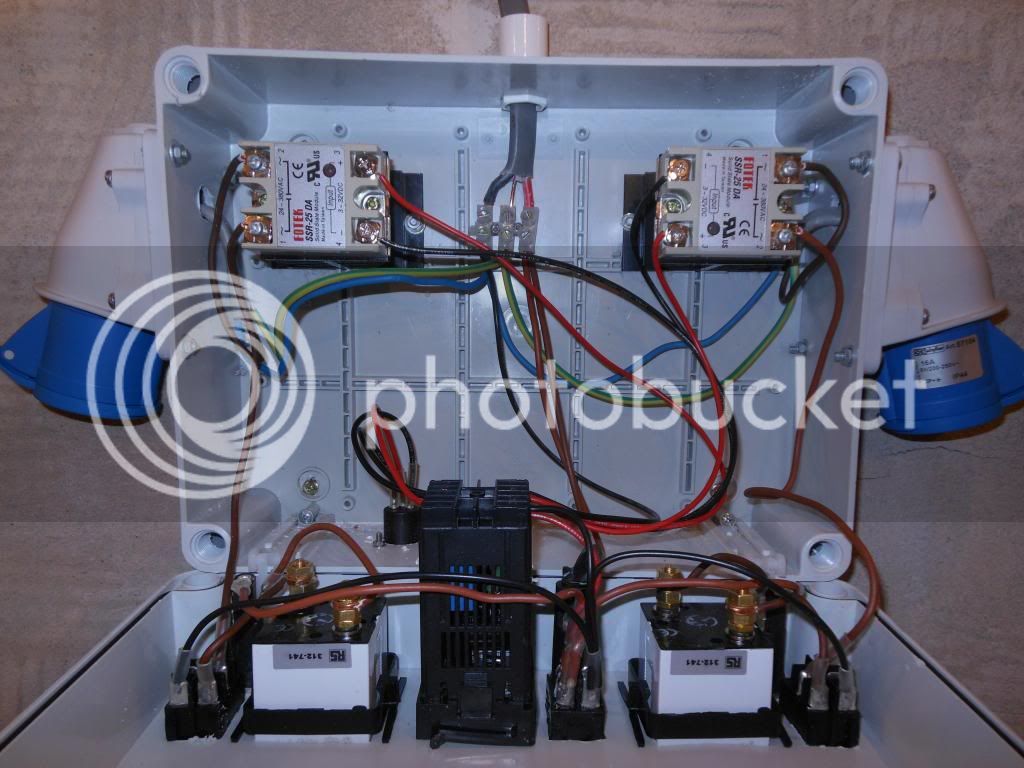

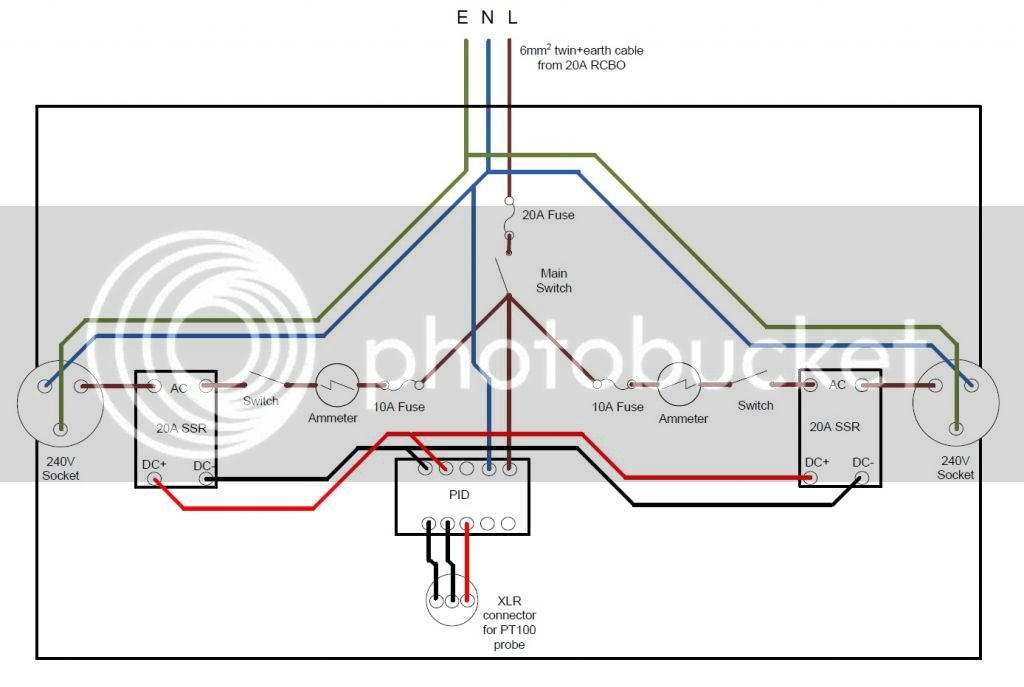

Hi Drayman - yes, it is for a two element HLT. I'll get some photos of the internals up when I've completed it, it is still in the prototype phase. Should be sometime this week though...

RokDok - I look forward to the conical how-to! :thumb: I assume you are talking about a jacketed version for temperature control - that would be a dream, and I suspect a bit more of a DIY challenge than HERMs (unless you have welding skills, I certainly don't).

Early on, once I just had pots with taps fitted, I decided I'd start trying to brew and that would influence my thinking on what extras to add next. I think that was a good idea, as some things I was sure I would need I quickly learned I could do without in the short-term, and other things suddenly became more important.

For example, I almost didn't start brewing, thinking a wort chiller was critical. I'm now past AG#5 and still am in no hurry to get one. It obviously is preferable to cooling over-night, but it has fallen down the priority list.

On the other hand, the HLT temperature control is great, as without it I was always forgetting to turn it on/off at the right times, as there was always something else going on.

HERMS I always thought would be well in the future. But my main source of frustration at the moment is getting the mash temperature right. HERMS will let me control that accuratly. And having sorted out the PID for the HLT, HERMS now looks to be a fairly simple step from where I am, both technically and finanically. I'm going to try making a spinny sparge arm (useful for regular fly sparging too), and provided that works ok, the HERMS heat-exchanger and PID control is a simple addition. I've read the arguements for and against, and I'm sure there are good points on both sides, but for me I just want to control the mash temperature and keep it constant.