Steved53

Junior Member

Just read a post about syphoning problems, and thought I would post how I go about moving the beer out of the fermenter.

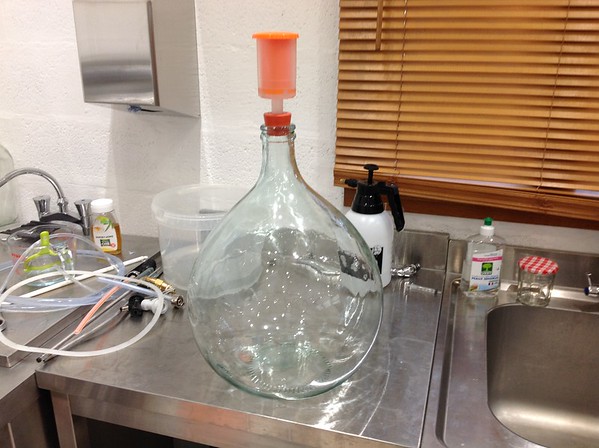

I use exclusively Speidel fermenters. The technique could well be used on other fermenters, but I haven't tried any.

The first thing I did was order a few spare caps off eBay and drill a hole in one of them:

Then I fitted one of these:

When you are coming towards the end of fermentation, you can remove the airlock and fit the cap with the Cornelius gas post. If you are concerned at this stage of too much pressure building up, then add a spunding valve to the gas post, set to around 2 or 3 psi.

When you are ready to transfer, connect up your gas bottle to your gas post, making sure the gas bottle is turned off, and your pressure adjustment is set to minimum. Caution! It would be easy to blow up the fermenter if you screwed this part up.

I have found that irrigation system fittings provide a nice tight fit on the end of the Speidel tap:

Fit it on backwards, so that when you open the Speidel tap, the irrigation tap is facing you and can be used to easily stop the flow.

This can be used as is, with the open end of the pipe (which is attached to the irrigation fitting) placed inside the receiving vessel - in my case Cornelious kegs.

This last time I decided that I wanted to try and keep everything sealed, with only the air release on the Cornelius keg being opened as the keg filled up. The only problem was I had run out of tops with air releases, so the top had to be left loose.

Anyway, I still wanted to see whether I could manage to do it with whatever I had around, and this is what I came up with:

The purpose of this was to get from the large diameter pipe which was attached to the Speidel tap to the liquid out Cornelius fitting. The metal fitting is what you attach to a co2 regulator to provide a barb end for your tubing. The thread is the same as the Rainbird irrigation fitting. A bit of a hotpotch, but it's what I had lying around.

This isn't a great photo, but it should give an idea:

I should have previously moved the fermenter to the top shelf, in order that the pressure required to move the beer wasn't too great. As it was, I didn't have any problems. I allowed it to transfer gently, and it all worked well. If you have allowed the pressure to build up naturally at the end of fermentation, there is no necessity to open up the gas until the transfer starts to slow right down, or stop. When it does VERY GENTLY adjust the pressure adjustment until it just starts to flow.

I don't like the idea of filling the keg until beer starts spurting out of the pressure release valve. Next time I'm going to attempt to weigh the kegs as the fill progresses and stop when there is still a little headroom at the top of the keg.

I use exclusively Speidel fermenters. The technique could well be used on other fermenters, but I haven't tried any.

The first thing I did was order a few spare caps off eBay and drill a hole in one of them:

Then I fitted one of these:

When you are coming towards the end of fermentation, you can remove the airlock and fit the cap with the Cornelius gas post. If you are concerned at this stage of too much pressure building up, then add a spunding valve to the gas post, set to around 2 or 3 psi.

When you are ready to transfer, connect up your gas bottle to your gas post, making sure the gas bottle is turned off, and your pressure adjustment is set to minimum. Caution! It would be easy to blow up the fermenter if you screwed this part up.

I have found that irrigation system fittings provide a nice tight fit on the end of the Speidel tap:

Fit it on backwards, so that when you open the Speidel tap, the irrigation tap is facing you and can be used to easily stop the flow.

This can be used as is, with the open end of the pipe (which is attached to the irrigation fitting) placed inside the receiving vessel - in my case Cornelious kegs.

This last time I decided that I wanted to try and keep everything sealed, with only the air release on the Cornelius keg being opened as the keg filled up. The only problem was I had run out of tops with air releases, so the top had to be left loose.

Anyway, I still wanted to see whether I could manage to do it with whatever I had around, and this is what I came up with:

The purpose of this was to get from the large diameter pipe which was attached to the Speidel tap to the liquid out Cornelius fitting. The metal fitting is what you attach to a co2 regulator to provide a barb end for your tubing. The thread is the same as the Rainbird irrigation fitting. A bit of a hotpotch, but it's what I had lying around.

This isn't a great photo, but it should give an idea:

I should have previously moved the fermenter to the top shelf, in order that the pressure required to move the beer wasn't too great. As it was, I didn't have any problems. I allowed it to transfer gently, and it all worked well. If you have allowed the pressure to build up naturally at the end of fermentation, there is no necessity to open up the gas until the transfer starts to slow right down, or stop. When it does VERY GENTLY adjust the pressure adjustment until it just starts to flow.

I don't like the idea of filling the keg until beer starts spurting out of the pressure release valve. Next time I'm going to attempt to weigh the kegs as the fill progresses and stop when there is still a little headroom at the top of the keg.