ThreeSheets

Active Member

- Joined

- Sep 29, 2012

- Messages

- 50

- Reaction score

- 11

Hi folks,

I was wondering if someone could lend a hand with troubleshooting on cloudiness here.

I used irish moss (super moss), I used immersion cooling, I filtered with nylon netting during transfer to the wort.

It came out clear before pitching the yeast as below shows:

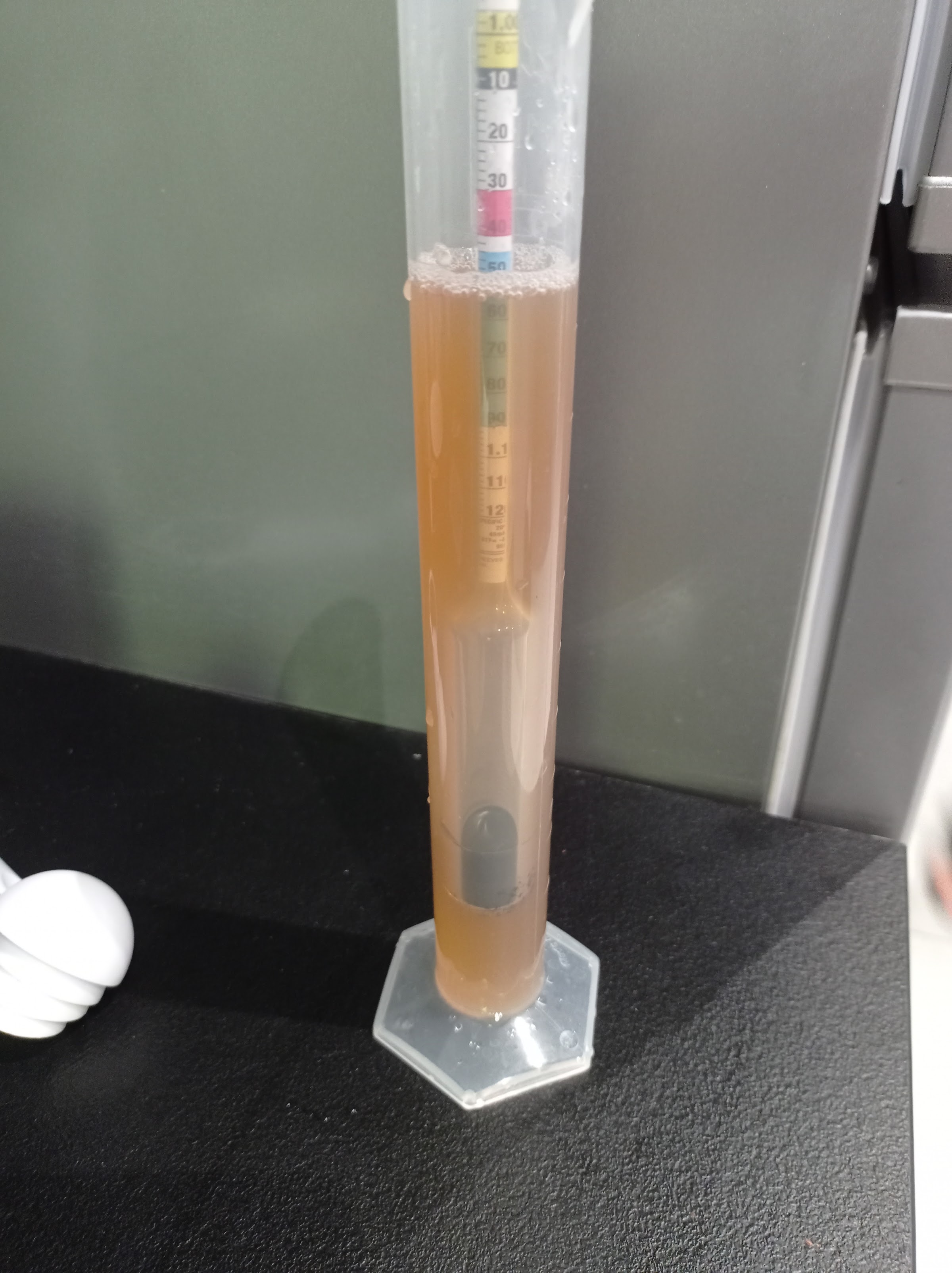

Bottled it after 2 weeks 5 days (controlling temperature of the FV in an water bath between 18-22°C), I was hoping for a very clear result and got quite the opposite:

I drank the sample - tasted good, smelled good and no indication of foreign organisms. What I really wanted was a clear result and nice colour to share with family and friends that don't really understand beer and might be a bit disturbed by non-commercial appearances. Will probably end up drinking it exclusively with the real beer nuts.

If you have any idea it would be greatly appreciated!

-------------------------------------------------------------------------------------------------------------------------

The more detailed description below if it helps (but don't waste your time if not required):

0. Rigorous sanitising of all equipment at all stages.

1. The night before - I crushed 5kg pale malt 10 SRM and 1kg Cara malt 3.5 SRM -> Final color 6SRM. Crush seemed okay, little flower, not too coarse, not too fine.

2. 60 minutes mash in a bag 20L strike water @ 74°C - with 10mL of 80% lactic acid in strike water to get to PH=5.2 - Held at about 68°C and stirred mash every 10 minutes.

3. Sparged the bag contents twice, with 5.5L of water each time @ 78°C

4. Boiled in 35g of cascade hop pellets for 60 minutes - Added in 5g of super moss 10 minutes before end of boil

5. Stuck the cooling coil in the wort shortly after and fished out the hop bag. Final kettle vol was 25L. It was a hot day and cold tap wasn't so cold, took perhaps 60 mins to get it down to 28-30°C range. Didn't stir during cooling.

6. Tapped off the wort into the FV, used a nylon net at the end of the hose to filter out some of the flour and fine particulate. Let it splash going in to get a bit of oxygen. Ended up with 23.8L of fermentable product.

7. Waited until 22°C to pitch the yeast - about 6 hours later. The yeast is M15 Empire Ale Yeast (mangrove jacks).

8. 2 weeks 5 days later -> bottled with 170g dextrose mixed in for 2.4 vols CO2.

-------------------------------------------------------------------------------------------------------------------------

Cheers,

ThreeSheets

I was wondering if someone could lend a hand with troubleshooting on cloudiness here.

I used irish moss (super moss), I used immersion cooling, I filtered with nylon netting during transfer to the wort.

It came out clear before pitching the yeast as below shows:

Bottled it after 2 weeks 5 days (controlling temperature of the FV in an water bath between 18-22°C), I was hoping for a very clear result and got quite the opposite:

I drank the sample - tasted good, smelled good and no indication of foreign organisms. What I really wanted was a clear result and nice colour to share with family and friends that don't really understand beer and might be a bit disturbed by non-commercial appearances. Will probably end up drinking it exclusively with the real beer nuts.

If you have any idea it would be greatly appreciated!

-------------------------------------------------------------------------------------------------------------------------

The more detailed description below if it helps (but don't waste your time if not required):

0. Rigorous sanitising of all equipment at all stages.

1. The night before - I crushed 5kg pale malt 10 SRM and 1kg Cara malt 3.5 SRM -> Final color 6SRM. Crush seemed okay, little flower, not too coarse, not too fine.

2. 60 minutes mash in a bag 20L strike water @ 74°C - with 10mL of 80% lactic acid in strike water to get to PH=5.2 - Held at about 68°C and stirred mash every 10 minutes.

3. Sparged the bag contents twice, with 5.5L of water each time @ 78°C

4. Boiled in 35g of cascade hop pellets for 60 minutes - Added in 5g of super moss 10 minutes before end of boil

5. Stuck the cooling coil in the wort shortly after and fished out the hop bag. Final kettle vol was 25L. It was a hot day and cold tap wasn't so cold, took perhaps 60 mins to get it down to 28-30°C range. Didn't stir during cooling.

6. Tapped off the wort into the FV, used a nylon net at the end of the hose to filter out some of the flour and fine particulate. Let it splash going in to get a bit of oxygen. Ended up with 23.8L of fermentable product.

7. Waited until 22°C to pitch the yeast - about 6 hours later. The yeast is M15 Empire Ale Yeast (mangrove jacks).

8. 2 weeks 5 days later -> bottled with 170g dextrose mixed in for 2.4 vols CO2.

-------------------------------------------------------------------------------------------------------------------------

Cheers,

ThreeSheets