I finally made my transition to the Dark Side on Sunday 12/12/10. I started brewing in January 2010 and have patiently watched while many of my THBF peers have jumped with both feet into the abyss... how I have longed to do the same :twisted:. The brew day was a success as a first attempt at the craft, but it wasn't without it's hitches. I brewed my own Pale Ale recipe, (which is yet another change from the recipe I posted the other day). I made a school-boy error of not checking the quantity of Cascade hops that I had based my entire recipe on! I went to weigh them out while mashing-in and found only 60g (recipe called for 100g). Thankfully I did have other hops in the freezer and decided on the following;

Broadford Pale

4kg Marris Otter

1kg Crystal Malt

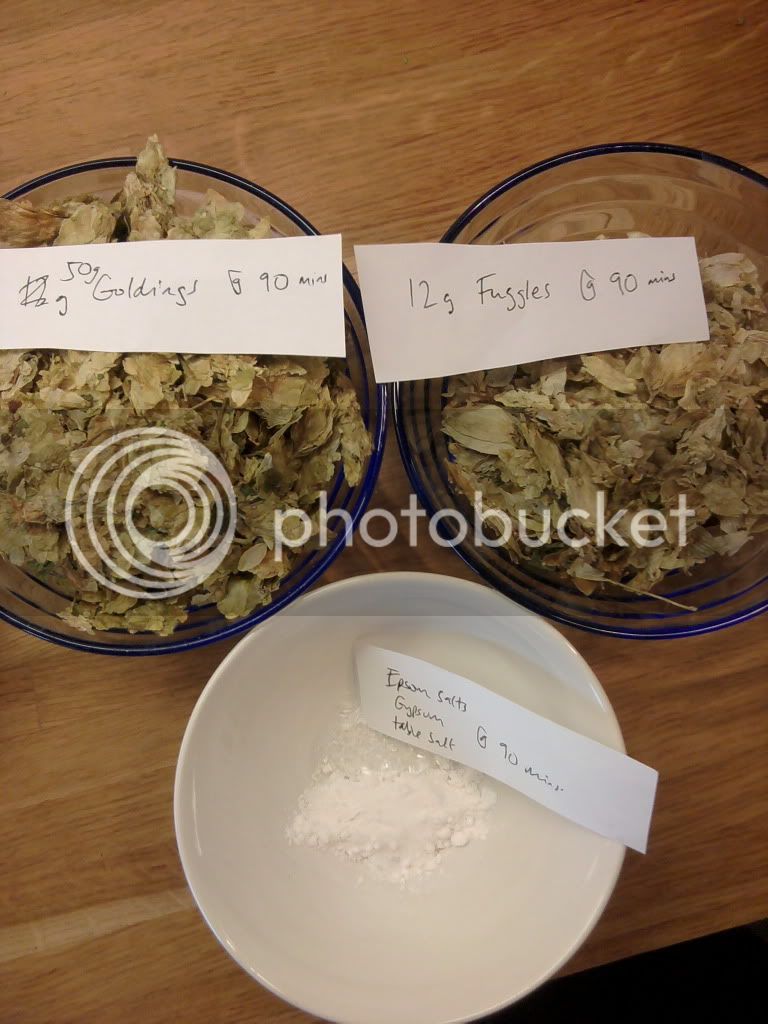

50g East Kent Goldings @90mins

12g Fuggles @90mins

25g East Kent Goldings @15mins

10g Cascade @15mins

Safale US-05

Expected OG 1045

Expected FG 1011

Expected ABV 4.5%

Expected IBU 35.0

Expected SRM 10.3

Loss calculations:

Mash tun dead space = 1.4L

Estimated loss to hops = 0.5L

Estimated loss to boil off = 2L

Estmated Loss to grain = 4L

Total loss = 7.9L

23L brew length target, so a total of 31L liquor needed.

I set up my 'stream-line' brewery, which consists of a 5 Gallon Cordon Brew 'Mark 2' Bruheat boiler and a Mash bag. I used the Bruheat Boiler as my HLT, Mash Tun and Boiler. I knew this would be a juggle, but it's what I have to play with, so I was happy to have a bash and maybe drop a few balls!

Started the HLT at 7am with 12.5L liquor (treated with a campden tablet), (based on ration of 2.5L / 1kg) and this was at strike temp of 78c in around 50mins.

Meanwhile I weighed the grain bill and gypsum addition and put them in the Mash/Grain bag.

I lowered the Mash Bag in to the 78c liquor and tried my bloody best to stir the porridge! Oh boy was this not easy.... and ultimately it did affect the efficiency of the sugar extraction (but more on that later). I did however manage to keep the Mash temp at a steady 68c for 90mins.

Lid on and went about weighing the hops and additions.

At the 70 minute mark I raised the temperature of the mash tun to 85c for mash-out, in an attempt to hit my target of 76c (I achieved 74c).

I started sparging, by having as much boiled kettle water at the ready, and started running the wort out of the HLT/MT/Boiler into a jug and recycling (all the while with an FV and sieve catching the rest

. I then switched between recycling the wort and adding the boiled kettle water to sparge (added a further 14.5L - giving a running total of 27L liquor).

I sparged like a manic thing :shock: and kept checking the gravity, until I felt that I was getting no improvement.. disappointingly this was only 1030. But this is also where I realised a gap in my knowledge... was this a problem at this stage? need to find out for next time.

I removed the Mash Bag and tried to get as much of the wort out as possible (which was futile!). Gave the HLT a quick rinse out to get rid of the grain-escapees and then added the wort back to the boiler and set to max (total 17.3L / 4.5G).

Time for a beer - thanks to Markp here... just sampling the AG TT Landlord's Apprentice we brewed :thumb:

At this point I removed 1L of unhopped wort and set this to boil in a pan on the hob. This was reduced to 200mls and added back to the boiler (really lovely caramel flavour!).

Acheived a rolling boil within 30 mins and skimmed most of the impurities that had formed on the surface.

First additions of 50g Goldings, 12g Fuggles and other additions (gypsum, epsom salts and table salt).

Second additions for last 15 minutes of the boil; 25g Goldings, 10g Cascade and a protafloc tablet.

Turned boiler off after 90 mins and started running the hopped wort off through a sieve and into an FV. Inevitably, with no hop stopper, the tap jammed up and despite my efforts I couldn't sort it. Resorted to removing the wort with a jug :|

Final volume was just shy of 15L with a disappointing gravity of 1.040.... so p1ssed off at this stage. My target was 1.045 and my inefficient mash forced my hand... I boiled up 600g soft brown sugar in 2L of liquor (now running total 29L) and added this to the FV. I pressed the trub in the boiler and tipped as much of the wort through the sieve as possible. This raised the gravity to 1.046....

(I decided to stick with 17L @ 1.046 and didn't want to liquor back and have a weeker beer).

Covered the FV and placed in a sink of iced water (refilled once the water warmed up) and achieved a good cold break.

Left the wort to cool to 22c and pitched the yeast... all tucked up, done and dusted

A big thank you to all that have given me advice along the way and a special thanks to my Jedi master MarkP :thumb:

What a fantastic day! It took me about 6 hours (plus some clear up time), but I did have some fun and games with the boiler - so a fair bit of hanging around!)

![BREWING THERMOMETER STICKERS ACCURATELY MONITOR FERMENTING BEER & WINE LIQUID TEMPERATURES 5PCS HOME BREW SPIRITS WINE LCD ADHESIVE [US]](https://m.media-amazon.com/images/I/311DDjo2X3L._SL500_.jpg)