Hi all,

Unfortunately I have not been brewing much lately, I bought a VW van during lockdown and spent the last 18 months stripping it out and converting it into a camper, took up so much of my time that I was unable to focus on anything else! Fast forward to today and all of the recession/energy prices/interest rate hikes got me spooked so I sold the van and now I'm back to brewing!

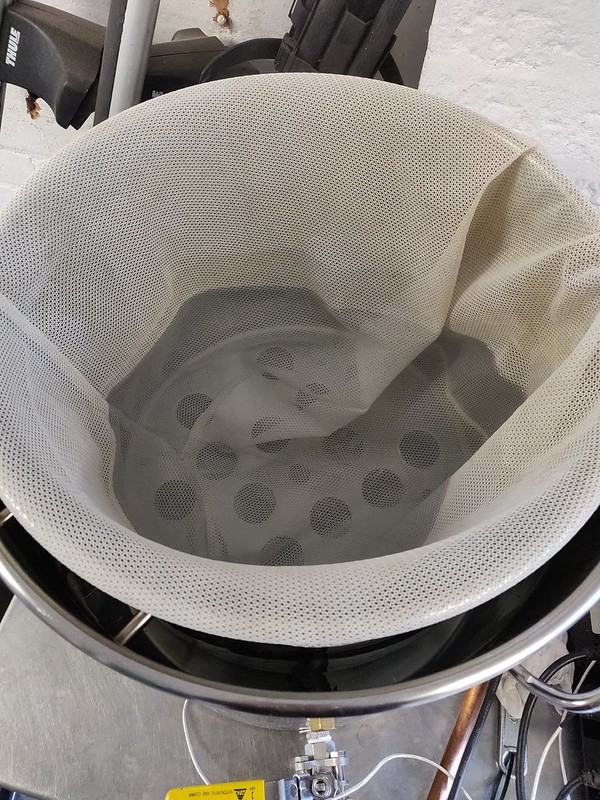

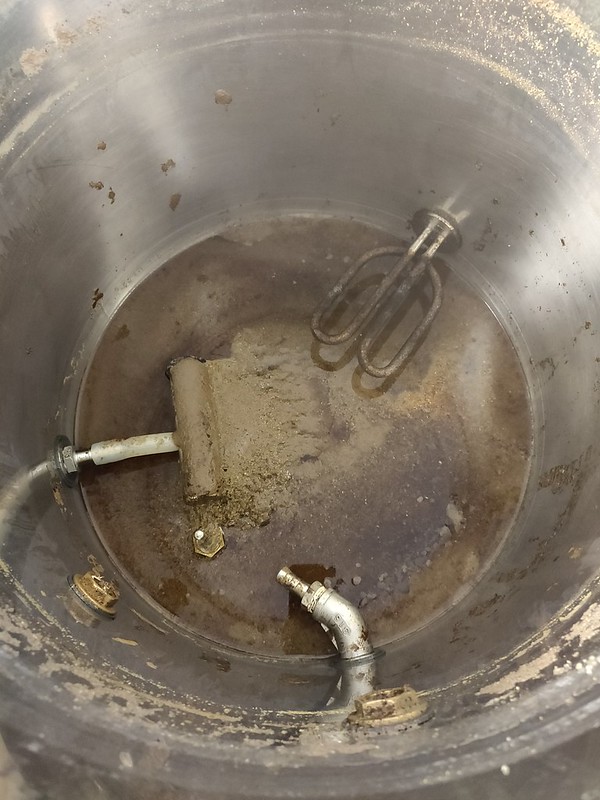

I have dusted down the MaltMother and have made a few tweaks. I ordered a few bits from Malt Miller (pump, grain bag), popped to BES and picked up some lovely stainless parts and here we go again:

Please excuse the messy garage! I have made a wooden trolley on wheels to minimise the amount of heavy lifting involved. The outer brew pot is secured to the trolley via bungee cords and by the bottom temp probe nut ensuring there's no serious movement. I did away with the separate pump inlet & whirlpool port as I found that the pump's draw is enough to pull the wort across the elements. Also my brewing controller can now limit the elements power to a specific % so no real chance of scorching.

4.8Kwh of boiling power needs limiting!

The pump really helps the immersion chiller with chilling times.

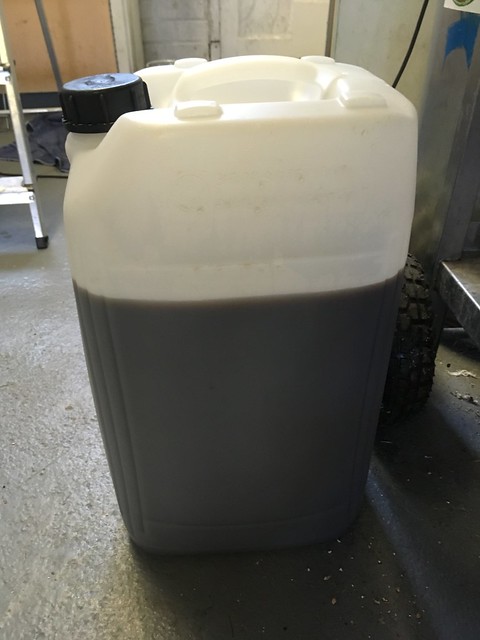

And transfer to the fermenter is really quick through the pump.

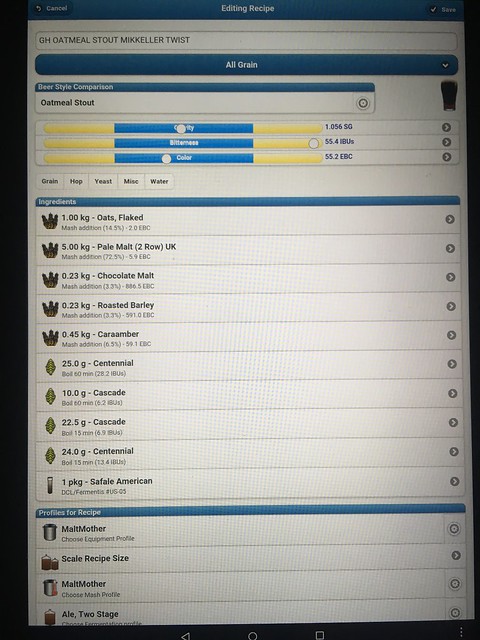

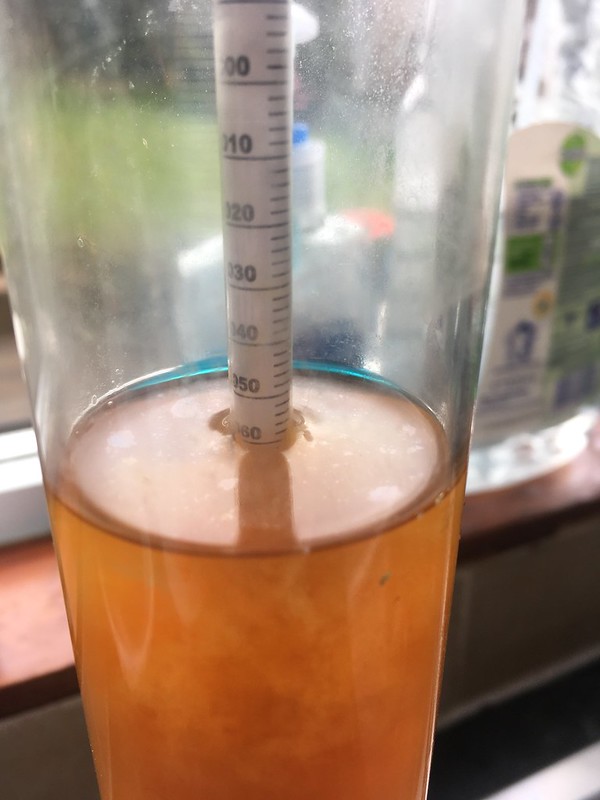

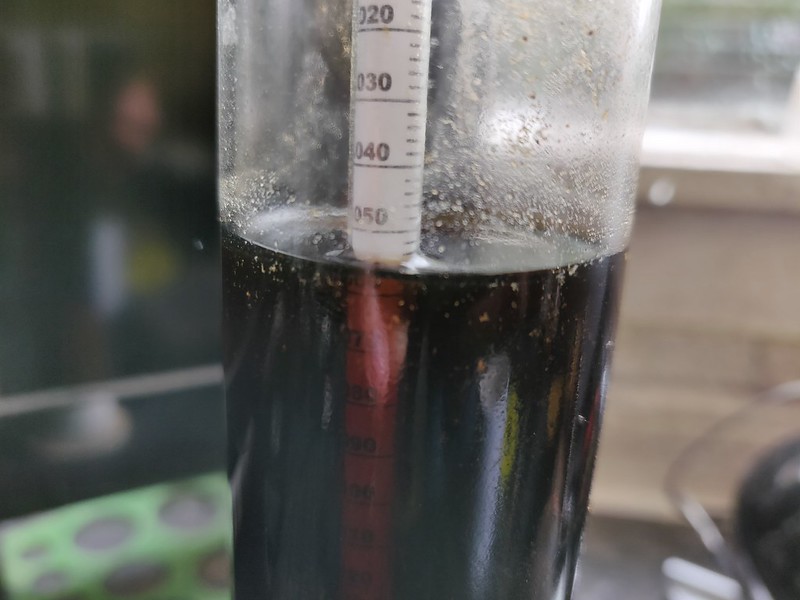

I brewed twice in 3 days over the bank holiday. Still dialing everything in and had to top up the fermenters to bring the OG down to something sensible so I need to do the maths on efficiency but I think it looks promising.

Have just added a recirculation arm setup inside the lid of the inner mashing pot to allow for the lid to be on during the mash and to help even out the flows (and no more pegs required to secure the hose!)

Its very good to be back and I'm looking forward to many more brews now. The latest brew was 3.5 hours start to finish so hopefully should save me a lot of time. Potential upgrades are to use a false bottom inside the grain basket instead of the grain bag, which I did try before and abandoned when I got a stuck mash once, but I think I can make it work better in this system. Also looking into hop spiders to allow recirculation straight into/through the hop spider when being held at 80.

Once the MaltMother is finished, I plan to make a counterpressure PET bottle filler (I don't use glass anymore) using a few bits and bobs in the garage.

Cheers,

Ben

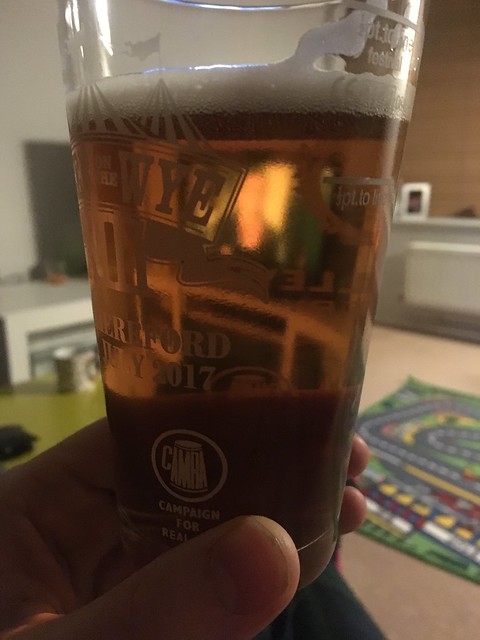

Columbus Chinook IPA by Ben, on Flickr

Columbus Chinook IPA by Ben, on Flickr

Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled

![BREWING THERMOMETER STICKERS ACCURATELY MONITOR FERMENTING BEER & WINE LIQUID TEMPERATURES 5PCS HOME BREW SPIRITS WINE LCD ADHESIVE [US]](https://m.media-amazon.com/images/I/311DDjo2X3L._SL500_.jpg)

IMG_20180921_090456

IMG_20180921_090456 IMG_20180921_093238

IMG_20180921_093238 IMG_20180921_095723

IMG_20180921_095723 IMG_20180921_105822

IMG_20180921_105822 IMG_20180921_113220

IMG_20180921_113220 IMG_20180921_125013

IMG_20180921_125013 IMG_20180922_130522

IMG_20180922_130522