You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Mad Russian - Imperial Stout

- Thread starter strange-steve

- Start date

Help Support The Homebrew Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

user 17085

Landlord.

- Joined

- Oct 8, 2016

- Messages

- 5,713

- Reaction score

- 4,578

Bottling tomorrow?Just had a little peek and as you can see krausen is already starting to form so I just give it another blast with the paint stirrer to aerate again and back in the fridge.

F00b4r

Landlord.

Did you split your malts 50/50 for the mashes or move all the dark grains to the initial mash in an attempt to control pH of both mashes? I know you said you did add salts to the second mash but it was a little sparse on the details.

It will be interesting to see how that yeast copes. I did the 14.5% from James Morton's Brew book and stupidly switched out the Nottingham yeast for CML equivalent, without thinking about changed alcohol tolerance and it died at about 9.5%. I tried pitching Brett C in to finish it but the alcohol level just killed it stone dead without it moving even a point. By the way for that beer James recommends pitching at about 30% above what the calculators say; maybe not so relevant for you but if others are using other yeasts for similar beers.

It will be interesting to see how that yeast copes. I did the 14.5% from James Morton's Brew book and stupidly switched out the Nottingham yeast for CML equivalent, without thinking about changed alcohol tolerance and it died at about 9.5%. I tried pitching Brett C in to finish it but the alcohol level just killed it stone dead without it moving even a point. By the way for that beer James recommends pitching at about 30% above what the calculators say; maybe not so relevant for you but if others are using other yeasts for similar beers.

An Ankoù

Landlord.

I've seen stuff like that on Star Treck. Put it back in the fridge and bolt the doors for eternity.

And pray.

And pray.

strange-steve

Quantum Brewer

- Joined

- Apr 8, 2014

- Messages

- 6,027

- Reaction score

- 5,805

I did consider shifting the roasted malts around for pH purposes but in the end decided just to split the grist 50/50.Did you split your malts 50/50 for the mashes or move all the dark grains to the initial mash in an attempt to control pH of both mashes?

I used Bru'n Water to help with the bicarbonate addition for the first mash (my tap water has about 40 ppm alkalinity) but for the second mash I just took a stab in the dark and added 1/4 tsp of sodium bicarbonate thinking I could adjust it mid-mash if needed but it worked out OK.

Otherwise iirc, the water profile was something like 90 ppm calcium, 100 chloride and 75 sulphate.

Shame about your beer, how did it turn out anyway? This is my first time using kveik yeast but apparently Hornindal is good for 16%. We'll see

£10.49 (£349.67 / kg)

£11.96 (£398.67 / kg)

Mangrove Jack 3X ’s Craft Series Mead Yeast M05 (10g)

BrewCo

£32.95

£34.95

DIAH DO IT AT HOME Beer & Wine Making Starter Kit - Basic Equipment - All You Need in One Box Homemade Beer & Wine Home Brewing

do-it-at-home

£23.75 (£25.45 / 75 cl)

Kinsale Mead Co. Atlantic Dry Mead 70cl, Light, Off Dry, Refreshingly Different Award-Winning Honey Mead, 12% ABV

Amazon.co.uk

£5.41 (£0.02 / 100 ml)

Elderflower Sparkling Wine Yeast 5-25L Homebrew Wine, Mead, Cider, Ginger Beer

Acorns Farm

£62.70

Cider Making Kit - with Bottles - 10L/2 Gallon/20 Pints Home Brew Beer Ale Lager

247 Homebrew

£14.76

Digital Temperature Watch Heating Thermometer Home Brewing Tools for Wine Bottle

B&D DIRECT STORE

£6.59 (£235.36 / kg)

2X Bulldog Mead Yeast & Nutrient High Alcohol 28g for 20-25L

Virtuoso (VAT Registered)

£73.98

Sanitary clamp 2" (51mm) OD64mm Sanitary Tri-Clamp 90-Degree Pipe With Nipple And Electronic Thermometer, Stainless Steel 304 Home brewing(Without Thermometer)

DAN CHENG XIAN PENG SHI DA SHANG MAO DIAN

£437.77

HMCOCOOFM 4L 4" OD119mm * 1.5" OD50.5mm Copper Onion Head For Homebrewing,Thickness 1.5mm (With Thermometer)

weifangguanhuawangluokejiyouxiangongsi

F00b4r

Landlord.

I did consider shifting the roasted malts around for pH purposes but in the end decided just to split the grist 50/50.

I used Bru'n Water to help with the bicarbonate addition for the first mash (my tap water has about 40 ppm alkalinity) but for the second mash I just took a stab in the dark and added 1/4 tsp of sodium bicarbonate thinking I could adjust it mid-mash if needed but it worked out OK.

Otherwise iirc, the water profile was something like 90 ppm calcium, 100 chloride and 75 sulphate.

Shame about your beer, how did it turn out anyway? This is my first time using kveik yeast but apparently Hornindal is good for 16%. We'll see

Interesting that you still hit your mash pH then and good to know. My beer has been sealed up for about 9 months and I thought I would check on it last week, just in case the Brett C was still around (it was from the Malt Miller with a good date so I'm pretty sure it was fine going in). It was still at 1.054 and although it has some good flavours and no autolysis off flavours it is too rich at that FG. I have some Champagne yeast turning up this week to make one last ditch attempt at saving it, if that doesn't work then it is down the drain I think. I'm definitely going to try again though, so quite interested to see how your yeast choice gets on and if it affects the flavour in a good way or not. There is a slight Brett edge to it though and I might co pitch half the next batch with it again.

MyQul

Chairman of the Bored

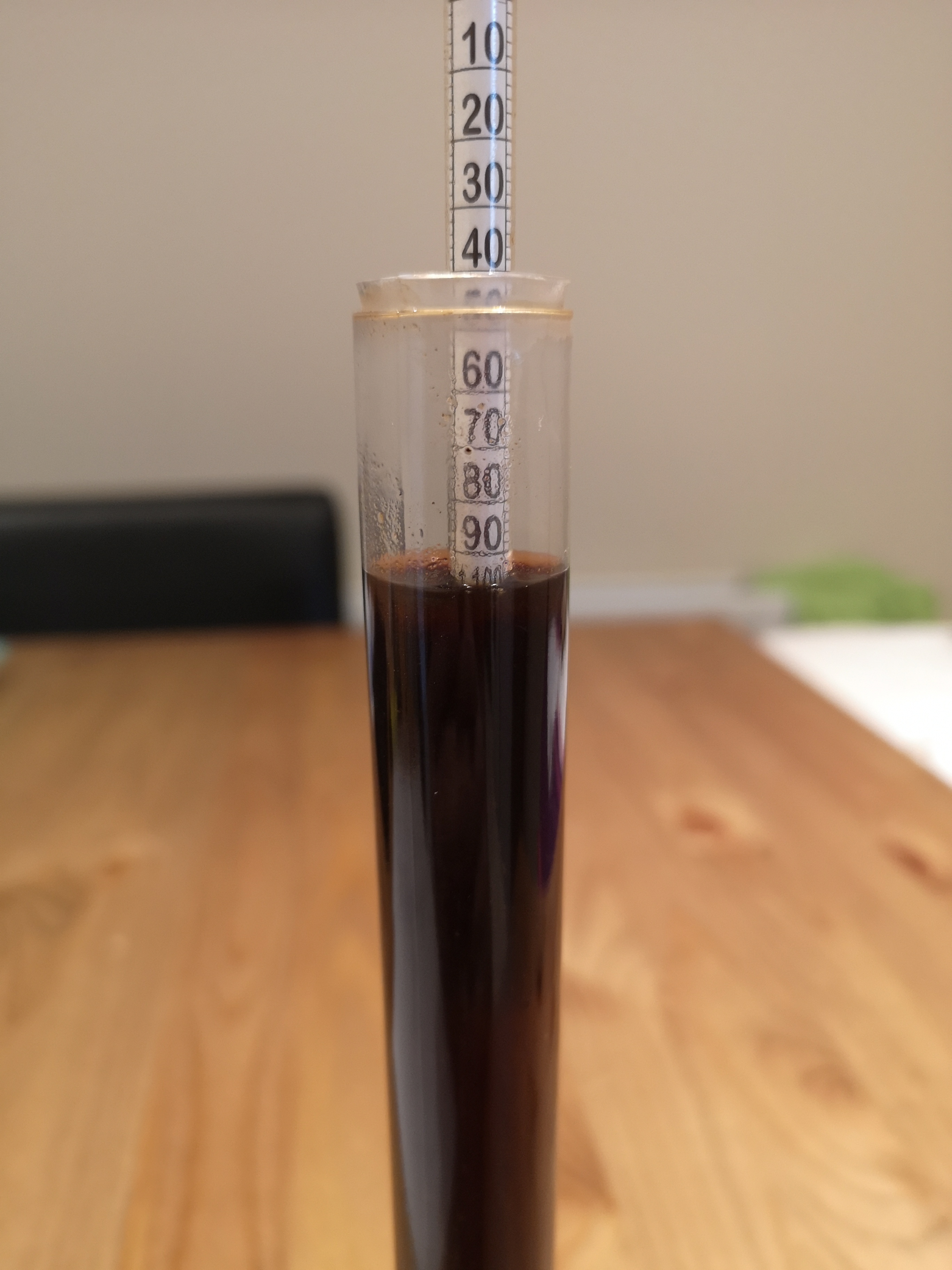

Back at it this morning and a rather interesting update. If you wondered if the reiterated mash is worthwhile as far as efficiency goes, have a look at the following picture. I had estimated a brewhouse efficiency of 60% which would require a pre-boil gravity of 1.075...

That's 1.096 meaning all else equal my BHE should be 76% which is crazy for such a big beer.

So this leaves me with a choice to make now:

1. Do I proceed as planned which would give me an OG of 1.168

2. Do I reduce the boil time so that I have a larger volume but OG is closer to 1.140?

3. Do I leave out the DME and half of the sugar for an OG of 1.147?

Go for the 1.168 monster

HoppyTommy

Junior Member

I showed my dad this thread tonight and he wants to know what you plan to carb the bottles with?

His suggestion was priming sugar and two paracetamol.

His suggestion was priming sugar and two paracetamol.

user 17085

Landlord.

- Joined

- Oct 8, 2016

- Messages

- 5,713

- Reaction score

- 4,578

The problem may not be alcohol tolerance, rather Brett C often doesn't metabolise maltose which makes up a large portion of wort.Interesting that you still hit your mash pH then and good to know. My beer has been sealed up for about 9 months and I thought I would check on it last week, just in case the Brett C was still around (it was from the Malt Miller with a good date so I'm pretty sure it was fine going in). It was still at 1.054 and although it has some good flavours and no autolysis off flavours it is too rich at that FG. I have some Champagne yeast turning up this week to make one last ditch attempt at saving it, if that doesn't work then it is down the drain I think. I'm definitely going to try again though, so quite interested to see how your yeast choice gets on and if it affects the flavour in a good way or not. There is a slight Brett edge to it though and I might co pitch half the next batch with it again.

Getting a source of glucoamylase in there could kick things off. A Saison yeast or even dry hopping might do it.

strange-steve

Quantum Brewer

- Joined

- Apr 8, 2014

- Messages

- 6,027

- Reaction score

- 5,805

When it's done I'm gonna do a group tasting along with this lot on the local park bench:I showed my dad this thread tonight and he wants to know what you plan to carb the bottles with?

His suggestion was priming sugar and two paracetamol.

F00b4r

Landlord.

The problem may not be alcohol tolerance, rather Brett C often doesn't metabolise maltose which makes up a large portion of wort.

Getting a source of glucoamylase in there could kick things off. A Saison yeast or even dry hopping might do it.

I did consider this, especially with regard to the Brett (I wasn't aware about C's issue with maltose and choose it mainly due to heritage reasons), but I pitched big initially with the sach, the alcoholic tolerance tied suspiciously with the level it died at (schoolboy error in switching yeasts) and although I have some 3711 I was a bit worried about it then just munching is way through almost everything and leaving a really dry thin beer. I might try throwing some dry hops in there with the Champagne yeast, what do you think?

user 17085

Landlord.

- Joined

- Oct 8, 2016

- Messages

- 5,713

- Reaction score

- 4,578

@F00b4r Won't hurt to throw some hops in, historically IPAs were dry hopped with a small addition despite being aged for a year. Ron Pattinson told me it was around 6-8oz per Barrel (1.37-2.75g/L). Presumably, using such a low rate in a aged beer, suggests this was to aid attenuation rather than for adding flavour or aroma.

I agree, alcohol tolerance was the issue with the Saccharomyces.

I agree, alcohol tolerance was the issue with the Saccharomyces.

An Ankoù

Landlord.

Bagsy the Tennent's Super. Yum, yum.

Zephyr259

Landlord.

Glad it's all going to plan this far, hope the yeast are up to the job. Thanks for the detailed report.

strange-steve

Quantum Brewer

- Joined

- Apr 8, 2014

- Messages

- 6,027

- Reaction score

- 5,805

Fermentation is chugging along this morning with some unusual and interesting smells coming from it.

An Ankoù

Landlord.

Expect a cloud to form above the cauldron with bats flying in and out of it and the occasional bolt of lightning.Fermentation is chugging along this morning with some unusual and interesting smells coming from it.

Last edited:

stigman

Landlord.

Better put a lock on your ferm fridge Steve. You dunno what evil that kveik yeast is creating.

Similar threads

- Replies

- 4

- Views

- 573

- Replies

- 0

- Views

- 375