Hawks

Landlord.

oldjiver said:I often thought of foaming my plastic bucket before I got my IGLOO, was it easy?

It is when a mate of yours sprays insulating foam for a living... :whistle:

oldjiver said:I often thought of foaming my plastic bucket before I got my IGLOO, was it easy?

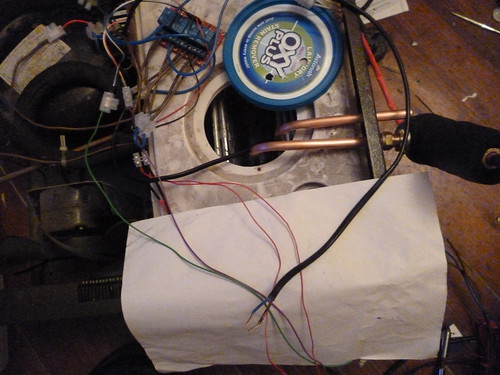

You get wet!!!anthonyUK said:Mine is a lot more basic.

I haven't even thought what to do when the weather turns yet.

No reason it can't be copied and pasted on THBF, a lot of mine we're/are, can't see it as a problem for either, more a 'gain' for bothThe 'other' homebrew forum

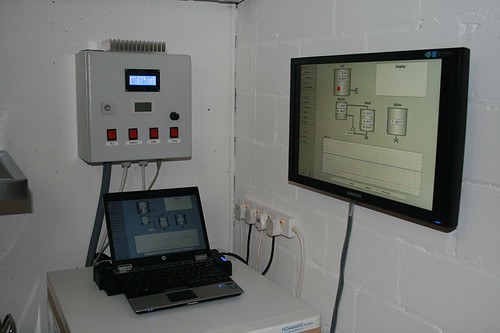

dennisdk2000 said:Just twigged that your MT is sat on scales (was trying to work out what the screen was for) - what a brilliant idea! :clap:

Dennis

barneey said:dennisdk2000 said:Just twigged that your MT is sat on scales (was trying to work out what the screen was for) - what a brilliant idea! :clap:

Dennis

If you look closely enough there is another set under the boiler

artyb said:i like the look of the hop spiders ...

anyone got any methods for making one..?

might add one to my minimalistic biab kit...

Enter your email address to join: