Okay I've read the 'How to's', been linked to 'Youtube' multiple times, so here's the stupid questions

Going to start building my AG setup over the next week and sadly its the plastic route, but its a start.

Boiler

Are THESE the Tesco kettles I've read so much about and is the size to drill out 40mm? Also do I use an auger bit or spade, which works better?

Tank backnut flanges 20mm?

Mash tun

Daab's false bottom or 15mm copper tube with slots, what depth should the slots be?

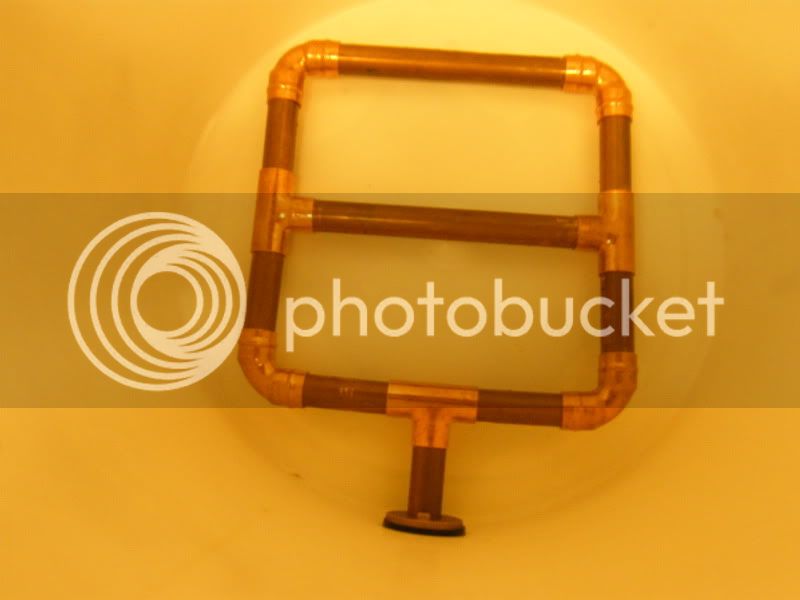

Spargers

15mm copper rectangle 1mm holes or use the shower head I have? :pray:

I'm sure they'll be plenty more question, but think that's it for now.

Sean

Going to start building my AG setup over the next week and sadly its the plastic route, but its a start.

Boiler

Are THESE the Tesco kettles I've read so much about and is the size to drill out 40mm? Also do I use an auger bit or spade, which works better?

Tank backnut flanges 20mm?

Mash tun

Daab's false bottom or 15mm copper tube with slots, what depth should the slots be?

Spargers

15mm copper rectangle 1mm holes or use the shower head I have? :pray:

I'm sure they'll be plenty more question, but think that's it for now.

Sean