Odd visual effect in the pic with the braid and FB fitted Bri

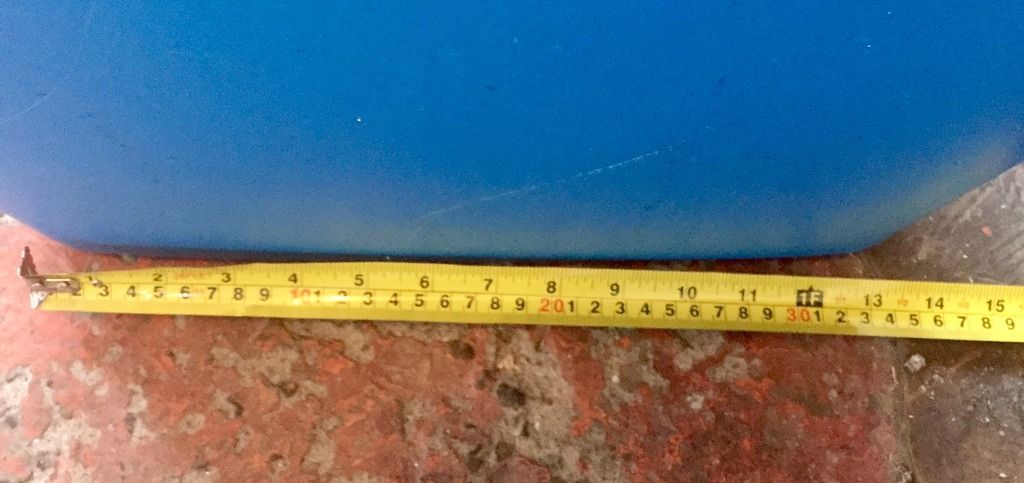

Fwiw Brians Tun pictured above uses a polycarbonate sheet circa 2-3mm thick

its a snug fit with the tun wall and its holes are just over 1mm in diameter spaced in a grid with an inch plus distance between holes, The legs are lead free brass screws securing 15mm pipe clips.

Reason i know its polycarb and not perspex is after brewing successfully without a single stuck mash with the above FB/Tun I upped my volume and kit and decided to make a similar FB from perspex. HA!!

well it lasted one brew, the perspex came out of the tun somewhat warped and

troubled by the 20kg of dry grain and water it had supported for 90 mins, and when it slipped from my hand only a few inches above the worktop it landed and shattered

However if your kitted up to work with SS sheet Go for it, I ended up buying a 2mm perforated plate cut to size from Mrlard. iirc you want something thats at least 30% open ..

Dont forget to post pics of the fabrication for all us brewporn junkies

![BREWING THERMOMETER STICKERS ACCURATELY MONITOR FERMENTING BEER & WINE LIQUID TEMPERATURES 5PCS HOME BREW SPIRITS WINE LCD ADHESIVE [US]](https://m.media-amazon.com/images/I/311DDjo2X3L._SL500_.jpg)