leedsbrew

Landlord.

- Joined

- May 15, 2009

- Messages

- 631

- Reaction score

- 5

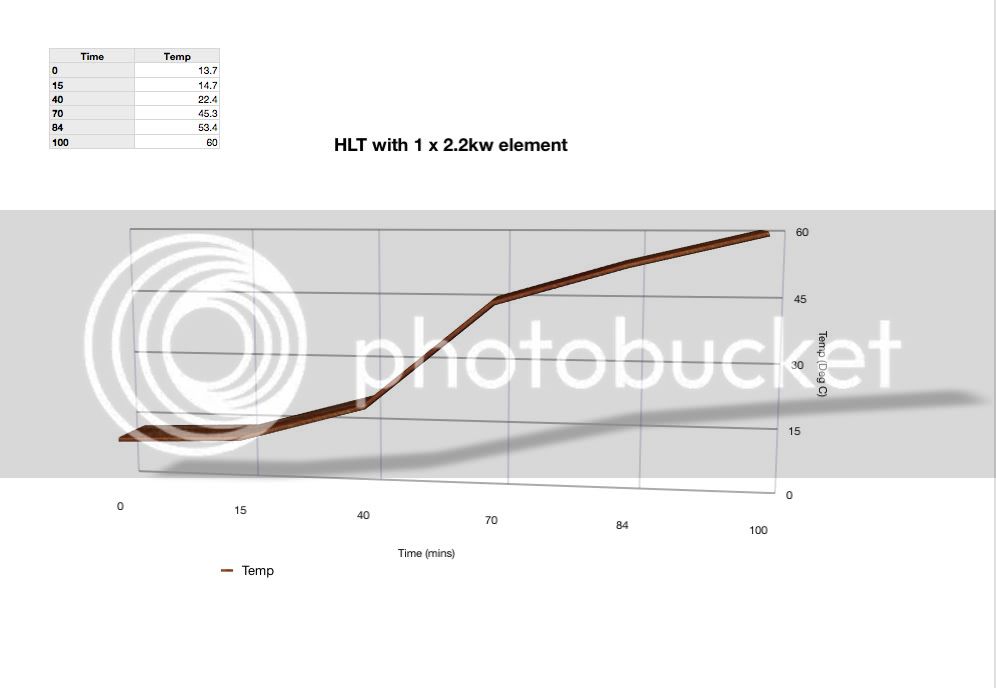

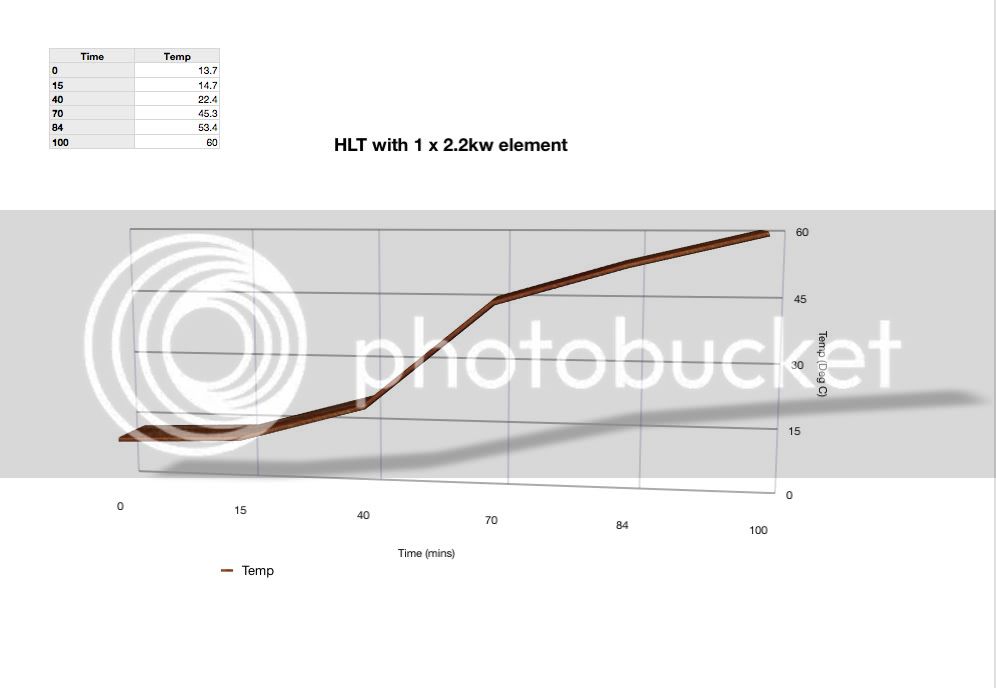

had a quick test of the heating ability of the HLT with one 2.2kw element whilst making tea last night. I've got a second element ready to put in but thought I'd have a quick play (with the tank :shock: )

With 65L of cold water (13.7 deg C) it took 1hr 40 mins to reach 60 deg C. Defiantly going to need a second element, although I usually use water from the hot tap for brewing.

And as I'm a massive geek I put the temp recordings into mac numbers and made this!

With 65L of cold water (13.7 deg C) it took 1hr 40 mins to reach 60 deg C. Defiantly going to need a second element, although I usually use water from the hot tap for brewing.

And as I'm a massive geek I put the temp recordings into mac numbers and made this!

![BREWING THERMOMETER STICKERS ACCURATELY MONITOR FERMENTING BEER & WINE LIQUID TEMPERATURES 5PCS HOME BREW SPIRITS WINE LCD ADHESIVE [US]](https://m.media-amazon.com/images/I/311DDjo2X3L._SL500_.jpg)