Mephistopholes

Well-Known Member

- Joined

- Mar 24, 2010

- Messages

- 190

- Reaction score

- 1

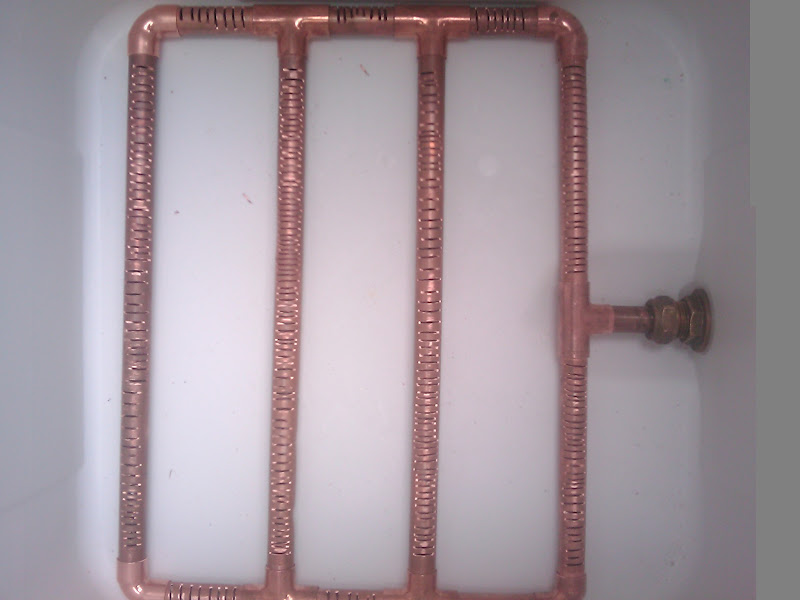

Just cut out the manifold. I was wondwring whether i could just drill holes with my 1.5mm drill bit or if i would have to use the hacksaw?

Round hole+round ish grain = blocked hole = no run offMephistopholes said:Slots or h9les? What difference? Theyre both as narrow as eab other.

Mephistopholes said:i would think as long as the pipe is rigid enough to take the weight of the grains and liquor, then it doesnt matter how flexible it is. hopefully going shopping this afternoon then building tomorrow. Btw copper is bloody expensive atm it seems.

Mephistopholes said:I need to cut the holes out on my hdpe bucket to insert the elements. the washer to hold them has an internal diametewr of 38mm. I have read that the best way to do this is a holesaw though ive just priced up at screfix for one holesaw and the arbor to hold it is gonna cost £9.50 or so. way too expensive to be cutting 2 holes.

so..

Does anyone know where to get one cheaper or is there an alternative. ive got a 1 inch drill bit and am planning to if nothing else comes along drill a one inch hole and gently run a very sharp knife round till i get the desired width.

:hmm:

Enter your email address to join: