Mickeywheelspin

Well-Known Member

- Joined

- Jun 14, 2013

- Messages

- 174

- Reaction score

- 21

Hi,

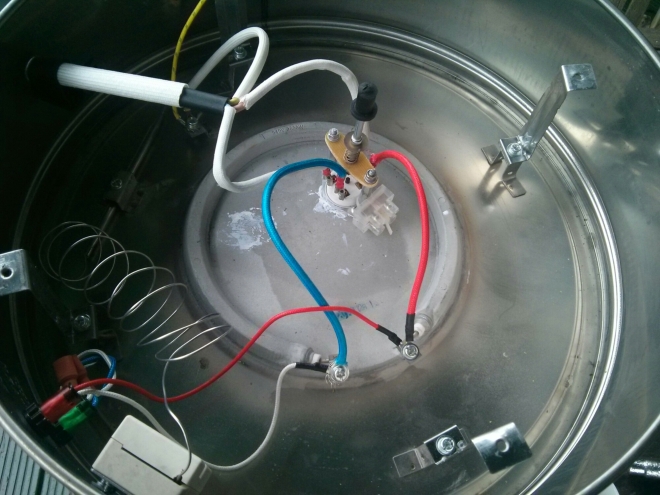

Long story short, I'm mid boil and my Buffalo is cutting in and out, what impact will this have on my brew? It gets to a rolling boil then stops for a couple of minutes then restarts.

I had issues with my first brew and had to tip it as the thermal fuse had blown. I bypassed the thermal fuse and cutout for the second brew which went really well but wanted to reintroduce a higher rated thermal cutout to prevent damage which I wired in last night - seems that 130 degrees isnt high enough. I cant remove the base to bypass it while its full so wondering if I just carry on and make the best of it or tip boiling liquid into an FV, bypass the cutout and carry on where I left off?

I don't fancy tipping boiling liquid to be honest, so what's the impact of a dodgy boil? I got hot break ok if that helps...

Thanks all.

Long story short, I'm mid boil and my Buffalo is cutting in and out, what impact will this have on my brew? It gets to a rolling boil then stops for a couple of minutes then restarts.

I had issues with my first brew and had to tip it as the thermal fuse had blown. I bypassed the thermal fuse and cutout for the second brew which went really well but wanted to reintroduce a higher rated thermal cutout to prevent damage which I wired in last night - seems that 130 degrees isnt high enough. I cant remove the base to bypass it while its full so wondering if I just carry on and make the best of it or tip boiling liquid into an FV, bypass the cutout and carry on where I left off?

I don't fancy tipping boiling liquid to be honest, so what's the impact of a dodgy boil? I got hot break ok if that helps...

Thanks all.