You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Automatic Underback

- Thread starter beer taster

- Start date

Help Support The Homebrew Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

evanvine

Landlord.

Many thanks MD, I was forgetting I didn't use a pumped system! (silly me)muddydisco said:Underback is small pot to collect the runnings out of the tun then the pump sucks from this. My system you seen hasn't got one so I have to balance the flow of the pump so it doesn't suck the grist to the bottom of the tun.

I Do like the look of this though and if all works out well, I may go this way when I upgrade.

Personally I wouldn't put live 240v through a float switch which is contact with the wort and hence the container. To be on the safe side you would have to earth the underback and use an RCD or something.

It would be better to use low voltages on the switches and isolation to a controller i.e PIC etc that controls a relay, mosfet, SSR etc to switch the pump on/off.

It would be better to use low voltages on the switches and isolation to a controller i.e PIC etc that controls a relay, mosfet, SSR etc to switch the pump on/off.

evanvine

Landlord.

Oh dear, will it be low voltage SS boilers and HLT's next?RatAle said:Personally I wouldn't put live 240v through a float switch which is contact with the wort and hence the container. To be on the safe side you would have to earth the underback and use an RCD or something.

I think that would be difficult, irony.

I would still connect the pot casing to earth for HLT and Copper, elements have been know to fail and the earth on the earthed element outer coating not detect the live fault inside the element. I would also bond all the pots together to prevent touch potentials between pots and pipework, pumps etc.

And of cousre the RCD on the lot

Best be safe than dead :shock:

If your'e a real fanatic, you could always brew with one hand in your pocket :!:

I would still connect the pot casing to earth for HLT and Copper, elements have been know to fail and the earth on the earthed element outer coating not detect the live fault inside the element. I would also bond all the pots together to prevent touch potentials between pots and pipework, pumps etc.

And of cousre the RCD on the lot

Best be safe than dead :shock:

If your'e a real fanatic, you could always brew with one hand in your pocket :!:

evanvine

Landlord.

Thank you for the gracious use of the word âIronyâ rather than âsarcasmâ as it undoubtedly was.RatAle said:I think that would be difficult, irony.

You are of course perfectly correct; I think the use of RCCBâs should be a standard.

Could be a bit difficult though with tropical fish tanks.

If you really go into it, the âRisk Assessmentâ of home brewing could be quite lengthy.

£7.00 (£70.00 / kg)

£7.25 (£72.50 / kg)

Youngs Multi Purpose Dried Active Yeast

TMJ.DISTRIBUTIONS

£11.95

£14.99

FOR THE LOVE OF HOPS (Brewing Elements): The Practical Guide to Aroma, Bitterness and the Culture of Hops

Amazon.co.uk

£8.99 (£158.55 / kg)

Fermaid O Yeast Nutrient - 2 oz (56.7 g) - Make Wine Cider Mead Kombucha at Home - Sold by CAPYBARA Distributors Inc.

CAPYBARA Distributors Inc. (UK)

£11.81

Digital Temperature Watch Heating Thermometer Home Brewing Tools for Wine Bottle

B&D DIRECT STORE

£11.95

£14.99

Brew it Yourself: Make Your Own Beer, Wine, Cider and Other Concoctions

ST Bookstores

£14.25

£18.99

How to Brew: Everything You Need to Know to Brew Great Beer Every Time

Amazon.co.uk

£38.63 (£0.39 / 100 ml)

Cider Making Kit - Full Starter - 10L/2 Gallon/20 Pints Home brew Beer Ale Lager

247 Homebrew

£6.99

Stevenson Reeves Triple Scale Hydrometer (S1011) For Home Brewing and Winemaking

Medi Exchange

£17.95

£24.95

DIAH DO IT AT HOME Fermenter 30l Fermentation Bucket with Tap, Airlock, Lid, and Bung, Homebrew Wine Making

do-it-at-home

£7.99

£14.99

Craft Brew: 50 homebrew recipes from the world's best craft breweries

Sarahs Bookshop UK

£11.95

£14.99

WATER COMPREHENSIVE GUIDE (Brewing Elements): A Comprehensive Guide for Brewers

Amazon.co.uk

£15.96

£16.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.co.uk

£11.08

Banziaju Wine Making Supplies, 18" Auto Siphon Hose For Water Homebrew Siphon Pump With Tubing And Clamp Clear Wine Siphon For Beer Wine Making Kit

Jian Shi Xian Chao Mei Shang Mao You Xian Gong Si

£63.25

Sanitary clamp 1.5" (38mm) OD50.5mm Sanitary Tri-Clamp 90-Degree Pipe With Nipple And Electronic Thermometer, Stainless Steel 304 Home brewing(Without Thermometer)

DAN CHENG XIAN PENG SHI DA SHANG MAO DIAN

£9.99 (£199.80 / kg)

Lalvin EC-1118 Wine Yeast (10 Pack) - Champagne Yeast - Make Wine Cider Mead Kombucha At Home - 5 g Sachets - Saccharomyces cerevisiae - Sold by CAPYBARA Distributors Inc.

CAPYBARA Distributors Inc. (UK)

beer taster

Well-Known Member

Yes maybe I need to rethink :hmm: I think JamesB is planning to do his underback that way. I have done some more testing this evening with the float switches installed in a plastic bucket, and the control seems to work fine turning the pump on + off.RatAle said:It would be better to use low voltages on the switches and isolation to a controller i.e PIC etc that controls a relay, mosfet, SSR etc to switch the pump on/off.

evanvine

Landlord.

All you would need is your float switches controlling a "low voltage" relay.beer taster said:Yes maybe I need to rethink

No mains voltage near your underback then!

jamesb

Landlord.

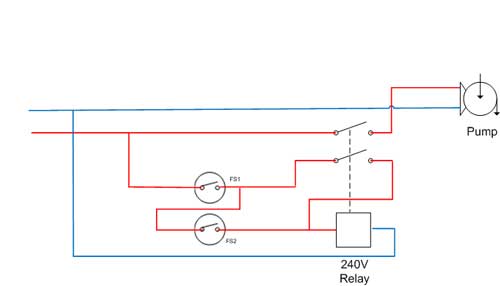

Here's a little something I made earlier

A little overengineered perhaps, but I've left the facility to have it PC controlled if I ever want it in the future.

And I just made it from bits I had lying around, so no comments on the design :grin:

A little overengineered perhaps, but I've left the facility to have it PC controlled if I ever want it in the future.

And I just made it from bits I had lying around, so no comments on the design :grin:

Two thoughts but this may just be the Cheeky Vimto. My sampling cup keeps getting bigger- I only have a 2 pint jug left to go now :P

Why not get float switches with NO and NC contacts? They must be available.

Alternatively can't you just mount the lower float the wrong way up. When the liquid is below the float gravity will make it flop down, turning off the pump. Once the liquid starts to rise, the float will lift up closing the contacts switching it on.

Why not get float switches with NO and NC contacts? They must be available.

Alternatively can't you just mount the lower float the wrong way up. When the liquid is below the float gravity will make it flop down, turning off the pump. Once the liquid starts to rise, the float will lift up closing the contacts switching it on.

unclepumble

Landlord.

Here are a few photos of mine, which is a March May off the shelf job. (i only use the small microswitch which switches the live, the large one just uses a flying lead to 3 wires)

http://i774.photobucket.com/albums/yy24/THBF/24.jpg

http://i774.photobucket.com/albums/yy24/THBF/25.jpg

http://i774.photobucket.com/albums/yy24/THBF/21.jpg

http://i774.photobucket.com/albums/yy24/THBF/22.jpg

http://i774.photobucket.com/albums/yy24/THBF/23.jpg

works a treat, microswitch made pump runs level drops pump doesn't, wired up to rcd, so safe as houses.

UP

http://i774.photobucket.com/albums/yy24/THBF/24.jpg

http://i774.photobucket.com/albums/yy24/THBF/25.jpg

http://i774.photobucket.com/albums/yy24/THBF/21.jpg

http://i774.photobucket.com/albums/yy24/THBF/22.jpg

http://i774.photobucket.com/albums/yy24/THBF/23.jpg

works a treat, microswitch made pump runs level drops pump doesn't, wired up to rcd, so safe as houses.

UP

jamesb

Landlord.

The almost finished product

I use flojet pumps, hence the solenoid valve. It turns on the air to the pump.

Just waiting on some 1/2" BSP locking washers that actually fit. The last lot I got from BES are next to useless.

I use flojet pumps, hence the solenoid valve. It turns on the air to the pump.

Just waiting on some 1/2" BSP locking washers that actually fit. The last lot I got from BES are next to useless.

That's looking good . . . but are you still planning on running it all at 240V? My personal thoughts would be to run it all at low voltage and use a 240V relay to control the pump.beer taster said:

The other thing you might want to consider, is that when the pump switches off wort will flow back into the under back from the pump side of the pipework . . . and if you have submerged your outlet pipework you will quite happily syphon out the contents of your mash tun

In order to use the underback between two levels that will give us enough buffer between not overflowing the underback and the pump not being primed and ran dry, two float switches can be used at a distance apart that will dictate the buffer volume. :thumb:

This can be implemented using relays, logic gates/flip flops, ROM lookup table, microcontrollers etcâ¦â¦

Because the system can have the same input conditions giving two different outputs, some kind of memory or latch will be needed. The simplest way to achieve and understand this is to use an algorithmic state machine; part of the state is used effectively as an input to differentiate.

From the diagram each circle represents a state the system can be in, above the horizontal line in the circle is the stimulus (our inputs), and below the line is the consequence (our outputs). The two switches (L and H) in the UB vessel are OFF if the liquid has not reached them and ON if the liquid reaches or passes them.

Assuming at the start we are in State 0 the inputs are tested and the corresponding output is applied and the state is changed accordingly. Note S1 and S3 have the same input conditions, but different outputs for the pump (P).

One such implementation for a microcontroller (uc) is shown above in pseudo code. It is important that the pump is switched off first, at initialisation when the uc is powered up. The above also assumes that the underback has no liquid in it at start up when entering State 0.

What if I forgot to power the uc and the underback already has some level in it ?

To protect from this scenario you could change the code in the initialisation routine.

Remove State = 0 and add:-

If (L off & H off) then State = 0;

If (L on & H off) then State = 1;

If (L on & H on) then State = 2;

i.e We have started in a different state due to the float switch values.

The initialisation routine is only called once at the start, the state machine is called in the main program loop either by polling or calling the routine after a time has elapsed, say every second (the liquid height wonât have changed much in that time). Mean while other things can be done in the loop.

You could also have some LEDâs reflecting the values of H, L and P and a buzzer for State S2, might look pretty :hmm:

Digressed a bit from brewing, so sorry if the above is a bit boring, some may find it interesting.

Cool system there Jamesb, did you do something similar :clap: ?

beer taster

Well-Known Member

As I'm lazy I plan to get it working with 240V then hopefully :whistle: change it to a lower voltage in the future..... provided I've not electrocuted myself by thenAleman said:... are you still planning on running it all at 240V?

Interesting point never thought about that, I'll make sure I don't submerge the return pipe in the boilerAleman said:... The other thing you might want to consider, is that when the pump switches off wort will flow back into the under back from the pump side of the pipework . . . and if you have submerged your outlet pipework you will quite happily syphon out the contents of your mash tun

jamesb

Landlord.

Cool system there Jamesb, did you do something similar :clap: ?

Spot on :thumb:

I forgot about the possibility of not turning it on whilst liquid was in it but it won't matter to my code. My electrics make that impossible anyway.

themadhippy

New Member

- Joined

- Dec 23, 2009

- Messages

- 5

- Reaction score

- 0

Why has everybody got a thing about 240v on the control circuit?there are 1000's of control circuits using 240v for the control circuit,some even use 415v,in far harsher environments than your homebrew shed.The switches in the original link are sealed and waterproof,although i cant find an IP ranting,with a built in cable.As long as the cable is terminated in a suitable enclosure theres very little risk of ingress from water or wort,put the control circuit in a suitably IP rated enclosures and you could chuck it in the liquid if the urge takes you.

rick_huggins

Active Member

unclepumble said:If I were you I would look for an automatic condensate pump, I use a march may condensate pump as an automatic underback and it works a treat, stainless steel box pump parts are all foodsafe and will take 120 deg c temp, and the float switch is allready fitted and wired in, all I needed to do was put a plug on it and fit the outlet pipework, it works a treat.

I have just done a search on fleabay, no march mays but this would probably do the job

http://cgi.ebay.co.uk/Aspen-Macerator-C ... 618wt_1165

It looks very very similar to mine & a bargain at £70.00

UP

I've just grabbed one of these; there's 6 left guys, £50

http://cgi.ebay.co.uk/ws/eBayISAPI.dll?ViewItem&item=140407900972&ssPageName=STRK:MEWAX:IT

The datasheets can be found here http://www.aspenpumps.com/en/macerator.html

Similar threads

- Replies

- 22

- Views

- 988

- Replies

- 36

- Views

- 2K

- Replies

- 16

- Views

- 2K

![BREWING THERMOMETER STICKERS ACCURATELY MONITOR FERMENTING BEER & WINE LIQUID TEMPERATURES 5PCS HOME BREW SPIRITS WINE LCD ADHESIVE [US]](https://m.media-amazon.com/images/I/311DDjo2X3L._SL500_.jpg)