I have finally got my shiny brewery all up and ready to brew with. All water tested and ready to go. Thanks to everyone who has helped this happen (physically, and with advice/stealing ideas). Special thanks go to MD for the shiny work he did, and Vossy for the silicone tubing. :thumb:

The connectors are from Intreco, and the pump is a Totton one from fleabay.

Enough wittering. Here are the pics:

Back of HLT with the 2 Backer elements installed using Q-Max 40mm cutter.

and the inside

and the sight tube. Nick, you were right on how much of a PITA it was to calibrate this, and ended up doing it to the litre, just to do the HLT justice!

Currently deciding whether to underlet the mash or just add the strike water, then grain? I have checked both configs with the pipework I have and they both work:

Standard strike

Underlet

Here is the recirc config and the return manifold

I have made a spinning sparge arm, using a compression tee where I nicked the olive on the down pipe and then took the nut off, put loads of PTFE on the thread and put the nut back on so it was tight on the thread, but not the olive. I have tested this with gravity feed and it spins, though maybe too quickly :) Last one is a video

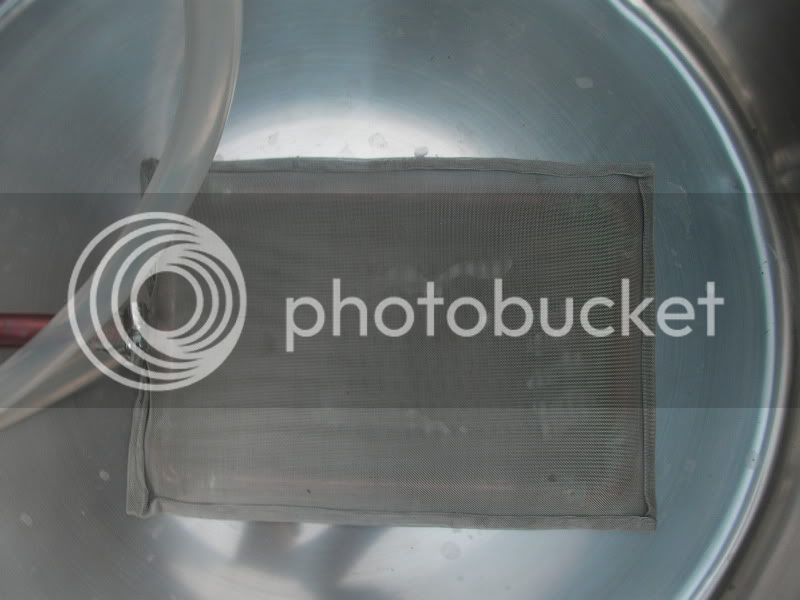

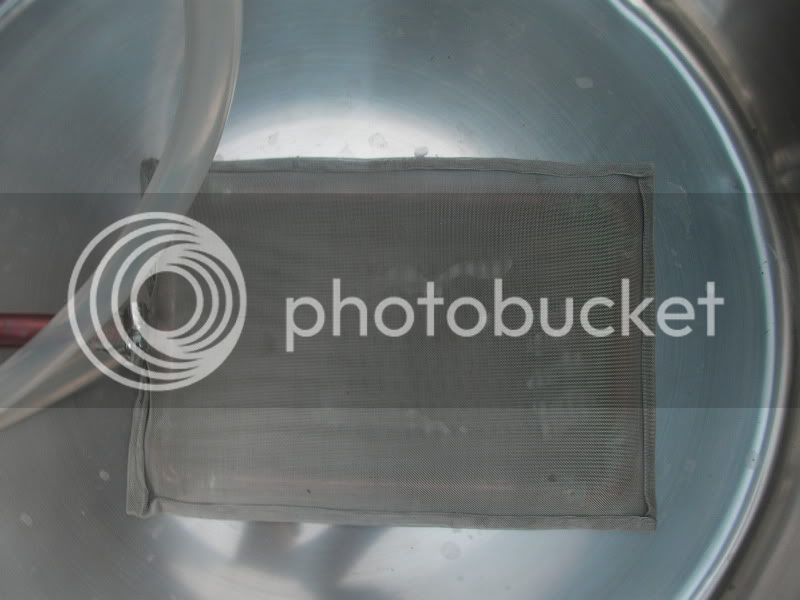

Here is the inside of the boiler with shiny hop stopper (rip off of MDs design)

And finally the recirc through the CFC configuration, saving the water from the CFC into the HLT for cleaning up afterwards.

Had great fun getting this together, and can't wait to use it, though will have to wait a couple of weeks as I have family commitments.

The connectors are from Intreco, and the pump is a Totton one from fleabay.

Enough wittering. Here are the pics:

Back of HLT with the 2 Backer elements installed using Q-Max 40mm cutter.

and the inside

and the sight tube. Nick, you were right on how much of a PITA it was to calibrate this, and ended up doing it to the litre, just to do the HLT justice!

Currently deciding whether to underlet the mash or just add the strike water, then grain? I have checked both configs with the pipework I have and they both work:

Standard strike

Underlet

Here is the recirc config and the return manifold

I have made a spinning sparge arm, using a compression tee where I nicked the olive on the down pipe and then took the nut off, put loads of PTFE on the thread and put the nut back on so it was tight on the thread, but not the olive. I have tested this with gravity feed and it spins, though maybe too quickly :) Last one is a video

Here is the inside of the boiler with shiny hop stopper (rip off of MDs design)

And finally the recirc through the CFC configuration, saving the water from the CFC into the HLT for cleaning up afterwards.

Had great fun getting this together, and can't wait to use it, though will have to wait a couple of weeks as I have family commitments.

![BREWING THERMOMETER STICKERS ACCURATELY MONITOR FERMENTING BEER & WINE LIQUID TEMPERATURES 5PCS HOME BREW SPIRITS WINE LCD ADHESIVE [US]](https://m.media-amazon.com/images/I/311DDjo2X3L._SL500_.jpg)