Springer

Its a dogs life

- Joined

- Oct 9, 2009

- Messages

- 1,445

- Reaction score

- 0

Hi all,

first post here, so if things are not quite right please forgive ?

Brewing thoughts

Where does the time go ?

I have been brewing for 5 years and feel a need to move on up the scale, for various reasons !

On a good day without problems, assuming everything is done at the alloted time, I think brewing operations take the following time :-

Heat water, weight out ingredients and mash 0.75

Mash 1.50

Sparge 0.50

Bring to boil 0.50

Boil 1.50

Cool, wash and tidy up 0.75

Total 5.50 Hours

The logic of the new proposed brewery, apart from fancying the challenge of a nice useful project, was to produce about three times as much beer in about the same time ?

That said, the savings are all down to heating up times. So I plan to move up from 5 gallon plastic buckets and go for a 15+ gallon plant along the following lines. Don't want to get involved with pumps and lots of cleaning in place at the moment, maybe I should be?

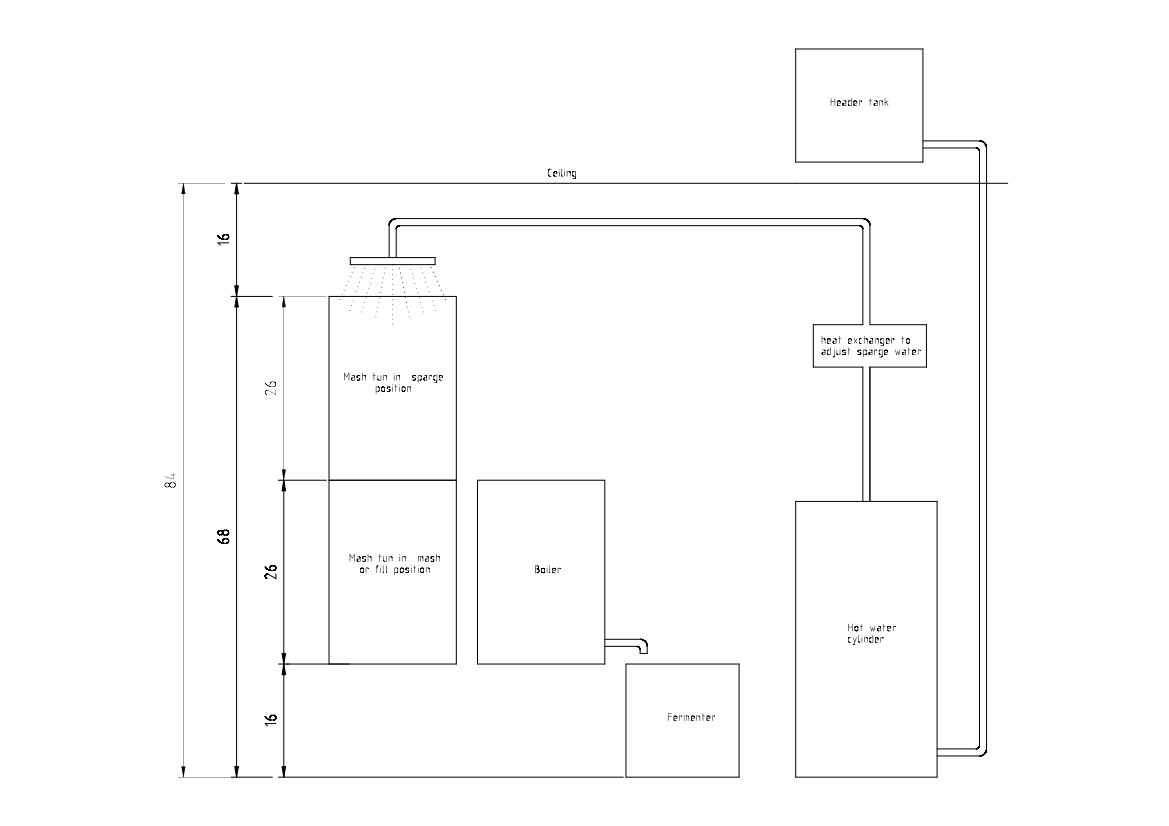

Plant design concept

If that does not work the drawings are available at http://www.pwhite.org.uk

Explanation of the process

Start the water heating in the hot water tank, ready for mashing, by a timer switching on two imersion heater giving 6 kw output.

Arrive in the brewery !

Run water onto mash tun steadily to settle strike temperature whilst ingredients are being weighted.

Add ingredients and leave to mash.

Leave hot water tank on to hear up sparge water.

Raise mash tun.

Run off wort.

Turn off hot water heaters, turn on 3kw heater in sparge water exchanger and start sparging.

Sparge.

Once sufficient water in boiler light gas burner and when covered turn on 3/6kw electric boiler heaters .

Turn down when boiling

Drain off boiler into fermenters, cool and add yeast.

Place in a fermenting cupboard insulated and heated, to ensure a consistant result.

Hopefully should be quicker than brewing 5 gallons and with less problems due to blocked or loose filters, heater packing up heat loss etc !

Comments are very welcome on any aspects of my proposal !

Best Regards

Springer

first post here, so if things are not quite right please forgive ?

Brewing thoughts

Where does the time go ?

I have been brewing for 5 years and feel a need to move on up the scale, for various reasons !

On a good day without problems, assuming everything is done at the alloted time, I think brewing operations take the following time :-

Heat water, weight out ingredients and mash 0.75

Mash 1.50

Sparge 0.50

Bring to boil 0.50

Boil 1.50

Cool, wash and tidy up 0.75

Total 5.50 Hours

The logic of the new proposed brewery, apart from fancying the challenge of a nice useful project, was to produce about three times as much beer in about the same time ?

That said, the savings are all down to heating up times. So I plan to move up from 5 gallon plastic buckets and go for a 15+ gallon plant along the following lines. Don't want to get involved with pumps and lots of cleaning in place at the moment, maybe I should be?

Plant design concept

If that does not work the drawings are available at http://www.pwhite.org.uk

Explanation of the process

Start the water heating in the hot water tank, ready for mashing, by a timer switching on two imersion heater giving 6 kw output.

Arrive in the brewery !

Run water onto mash tun steadily to settle strike temperature whilst ingredients are being weighted.

Add ingredients and leave to mash.

Leave hot water tank on to hear up sparge water.

Raise mash tun.

Run off wort.

Turn off hot water heaters, turn on 3kw heater in sparge water exchanger and start sparging.

Sparge.

Once sufficient water in boiler light gas burner and when covered turn on 3/6kw electric boiler heaters .

Turn down when boiling

Drain off boiler into fermenters, cool and add yeast.

Place in a fermenting cupboard insulated and heated, to ensure a consistant result.

Hopefully should be quicker than brewing 5 gallons and with less problems due to blocked or loose filters, heater packing up heat loss etc !

Comments are very welcome on any aspects of my proposal !

Best Regards

Springer

![BREWING THERMOMETER STICKERS ACCURATELY MONITOR FERMENTING BEER & WINE LIQUID TEMPERATURES 5PCS HOME BREW SPIRITS WINE LCD ADHESIVE [US]](https://m.media-amazon.com/images/I/311DDjo2X3L._SL500_.jpg)