beermaker said:

probably not - the level of carbonation is maintained by a pressure equilibrium at the surface of the beer. If you apply a pressure of, say, 6 PSI to the keg and leave it, the beer inside will absorb CO2 until a state of equilibrium is achieved. If you then reduce the pressure to 3 PSI, the beer will leach CO2 out of solution until the state of equilibrium is achieved again. This is also affected by temperature - the colder a liquid is, the more CO2 it will absorb before equilibrium is achieved at any given pressure.

Totally with you so far, gels with my limited understanding..

beermaker said:

Beer lines are often kept as short as possible as there is less pressure drop along a short line,.

dunno about this.. the loss of condition due to a nominal pressure drop is not a fast reaction, and in a comercial situation where beer is drawn daily may manifest in an initial splutter from the tap when opened,

in my limited experience (with my own set up) when left for a few weeks in a 3-4m length of 3/8" tube thru a shelf chiller to my flow control taps, the resulting condition loss in the pipe length manifests itself with the initial 1/3rd of a pint spluttering thru quite noisily and frothy, but soon settles down leaving the first pint with a 3 inch head, if i continue to pour.. i generally just dump "the Spit" down the sink its mostly gas anyway :) thru the 3/16th line i use for hi conditioned beers its just the same but less waste as less beer in the thin tube..

beermaker said:

so a lower working pressure is required to dispense the beer and as such a lower carbonation level is maintained in the beer. A higher carbonation level will lead to excessive foaming when the beer is dispensed due to the higher levels of CO2 leaching out of the beer as it leaves the tap.

NO sorry youve swerved off track from my understanding now.. ideally the beer is stored at a condition retaining pressure. kegs are connected and left till empty not nursed..

what causes massive foam release is a dramatic change, a dramatic change in temp can do it, a dramatic change in state can do it (drop a tinny), and a dramatic drop in pressure can cause it,, and its the dramnatic drop in pressure from a tap connected to a highly pressured keg that is at the root of many home kegging issues. cold beer into a warm glass just compounds the problem.

reducing the pressure gradient (pressure drop) at point of release - tap

will help. the restriction applied by the thin line is gradual along its length and is not dramatic, and if balanced with the keg pressure can provide a nominal drop in pressure between the beer and atmosphere, so when it hits the warmer glass that temp change wont just cascade the issue...

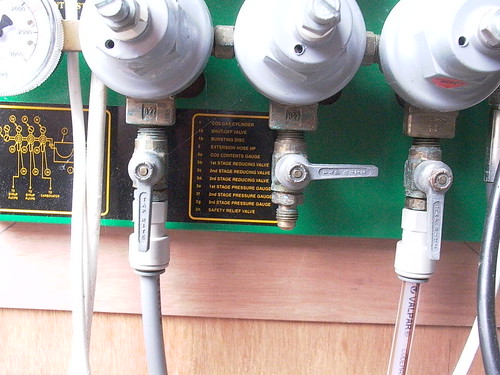

cornys are just a part of a dispensing system.. to get the best u want control over temp and pressure ( in and out), and if control is beyond your capacity understanding and confidence to shake the keg n vent or whak up the pressure for a day or 2 helps

I would like a keg fridge perhaps fitted on top of the w/machine :)