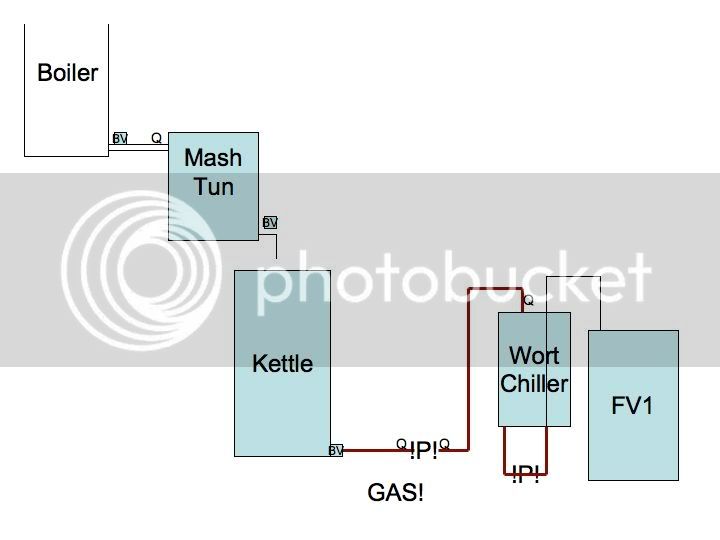

Well - here are my initial thoughts:

BOILER: The water runs from a ball valve into the top of the Mash Tun, through the wall of the box.

MASH TUN: There is a Quick Disconnect (labelled Q) at each end so that the Mash Tun can be removed from the system and cleaned. On the inside will be a another QD so that a T-piece with two small shower heads can be placed on and used as a sparging arm during sparging.

The wort flows into.......

WORT CHILLER: This is going to be a 23L keg with top sawn off at the top of the vertical ribbing, so it is open. This will have the copper coil inside which emerges at a Cam disconnect -> hose barb on the outside. The red lines are silione hose running through a pump and back into the chiller via a hose barb -> cam disconnect. Both will have thumb taps to seal the vessel for disconnection. On the inside, copper pipe continues up interweaving through the coils to give it extra strength before emerging and providing an open pipe outlet to fill the kettle.

Therefore the Wort Chiller can be disconnected from the silicone hose and mash tun and washed independently if needed.

KETTLE: Gas-fired with a ball valve exit running via hose to a pump. From here, more hosing will be used to fill the FV.

What do you reckon?

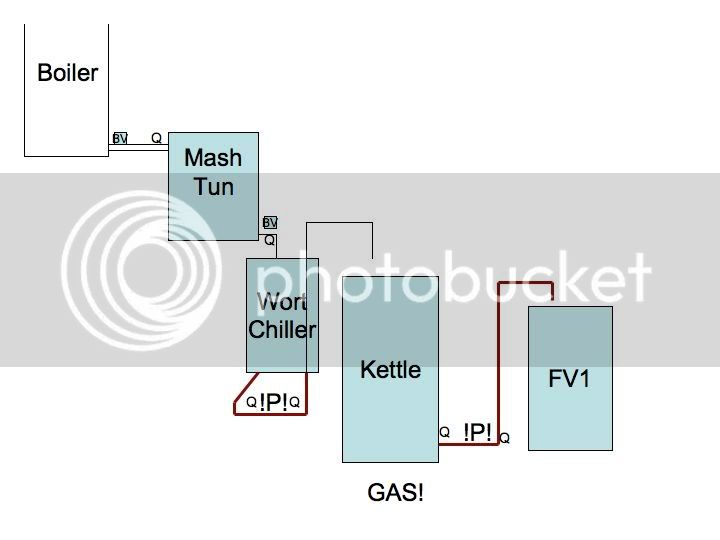

BOILER: The water runs from a ball valve into the top of the Mash Tun, through the wall of the box.

MASH TUN: There is a Quick Disconnect (labelled Q) at each end so that the Mash Tun can be removed from the system and cleaned. On the inside will be a another QD so that a T-piece with two small shower heads can be placed on and used as a sparging arm during sparging.

The wort flows into.......

WORT CHILLER: This is going to be a 23L keg with top sawn off at the top of the vertical ribbing, so it is open. This will have the copper coil inside which emerges at a Cam disconnect -> hose barb on the outside. The red lines are silione hose running through a pump and back into the chiller via a hose barb -> cam disconnect. Both will have thumb taps to seal the vessel for disconnection. On the inside, copper pipe continues up interweaving through the coils to give it extra strength before emerging and providing an open pipe outlet to fill the kettle.

Therefore the Wort Chiller can be disconnected from the silicone hose and mash tun and washed independently if needed.

KETTLE: Gas-fired with a ball valve exit running via hose to a pump. From here, more hosing will be used to fill the FV.

What do you reckon?