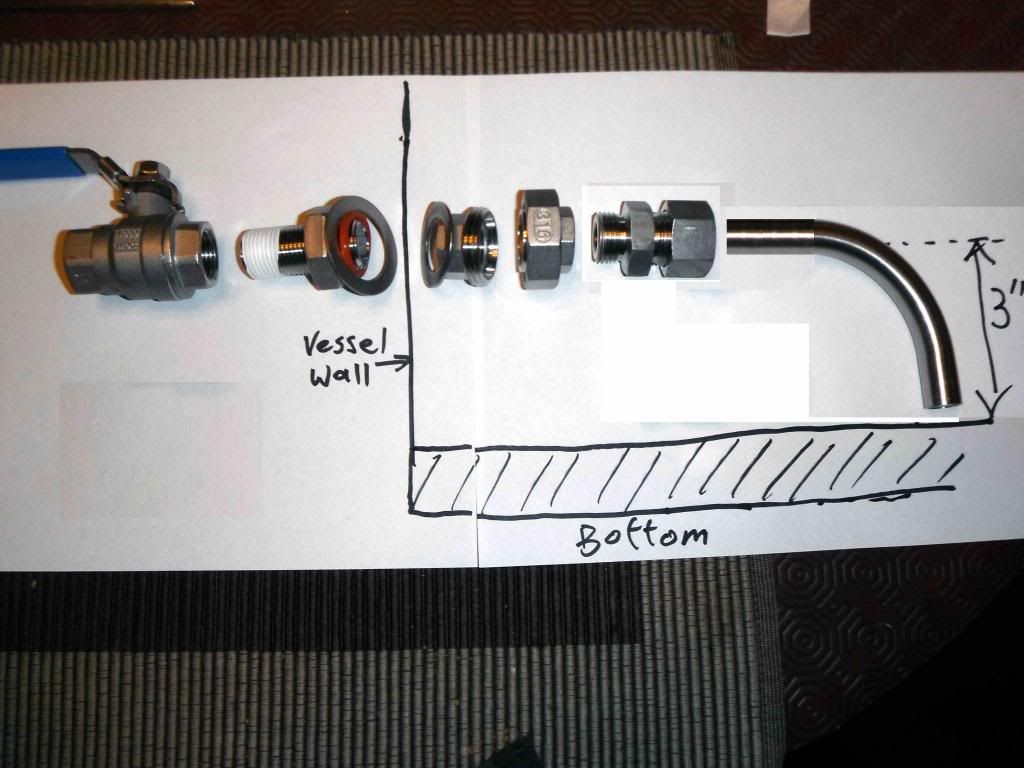

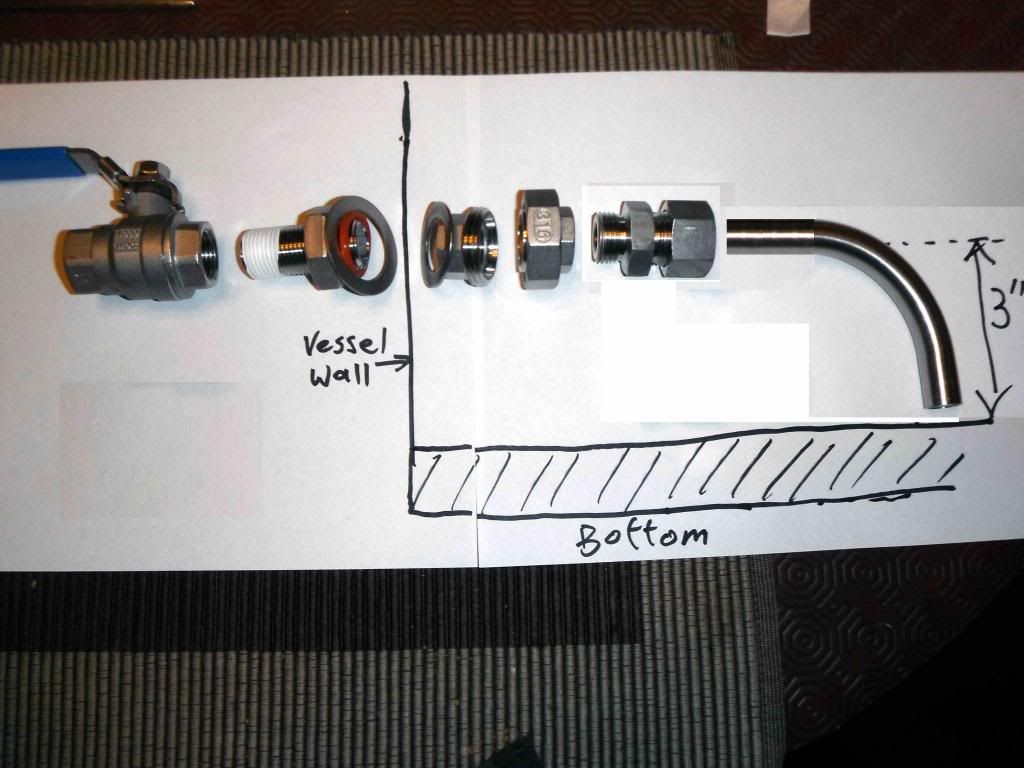

Iâve started the build on the HLT now, using one of Homebrewbuilderâs high-end 100L pots (http://www.homebrewbuilder.co.uk/). I used a 20.4mm Qmax cutter to cut a ball valve hole 3 inches from the bottom inside of the pot. I am using a weldless fitting to join the valve to the pot and a stainless steel 15mm dip tube for effective draining. The dip tube was bent to 45 deg using a manual pipe bending tool. The dip tube is joined to the valve outlet by using a male SS compression stud coupling 15mm x 1/2" BSP, which screws into a female cone seat union. This method allows me to twist the dip tube into the correct position before tightening the union joint and also allows the dip tube to be easily removed if I want to clean it out. The picture below shows how the tap is assembled.

This is what the assembled valve looks like on the inside:

The view of the pot from the outside:

Next stages on this pot are fitting a dial thermometer, a sight gauge, a 5500w element and a water input ball valve. Finally, I will attach a water output "T" connection for the temperature probe. Hopefully, more posts tomorrow.

This is what the assembled valve looks like on the inside:

The view of the pot from the outside:

Next stages on this pot are fitting a dial thermometer, a sight gauge, a 5500w element and a water input ball valve. Finally, I will attach a water output "T" connection for the temperature probe. Hopefully, more posts tomorrow.

![BREWING THERMOMETER STICKERS ACCURATELY MONITOR FERMENTING BEER & WINE LIQUID TEMPERATURES 5PCS HOME BREW SPIRITS WINE LCD ADHESIVE [US]](https://m.media-amazon.com/images/I/311DDjo2X3L._SL500_.jpg)