Hi guys.

I've just purchased 1 of these today

http://www.caravantech-shop.co.uk/produ ... 8-cool-box

And also this tank connector which is already drilled out to accept 15mm copper pipe

http://www.copperkettlehomebrewing.co.u ... -connector

Just a couple of questions regarding the installation of a ball valve tap....

I'm planning on installing the tank connector with the threaded end on the outside of the coolbox and the flat end on the inside with the rubber washer sealing against the inside face of the box.

After tightening this up I'm then planning to screw a 1/2 inch 2 piece ball valve tap onto the threads of the tank connector on the outside with PTFE tap to seal the threads.

This is the tap I'm talking about

http://www.themaltmiller.co.uk/index.ph ... ductId=411

Its a female 1/2" on both ends

Would this setup work OK with this particular coolbox? I've seen some other threads but its never very clear how people are hooking the taps up.

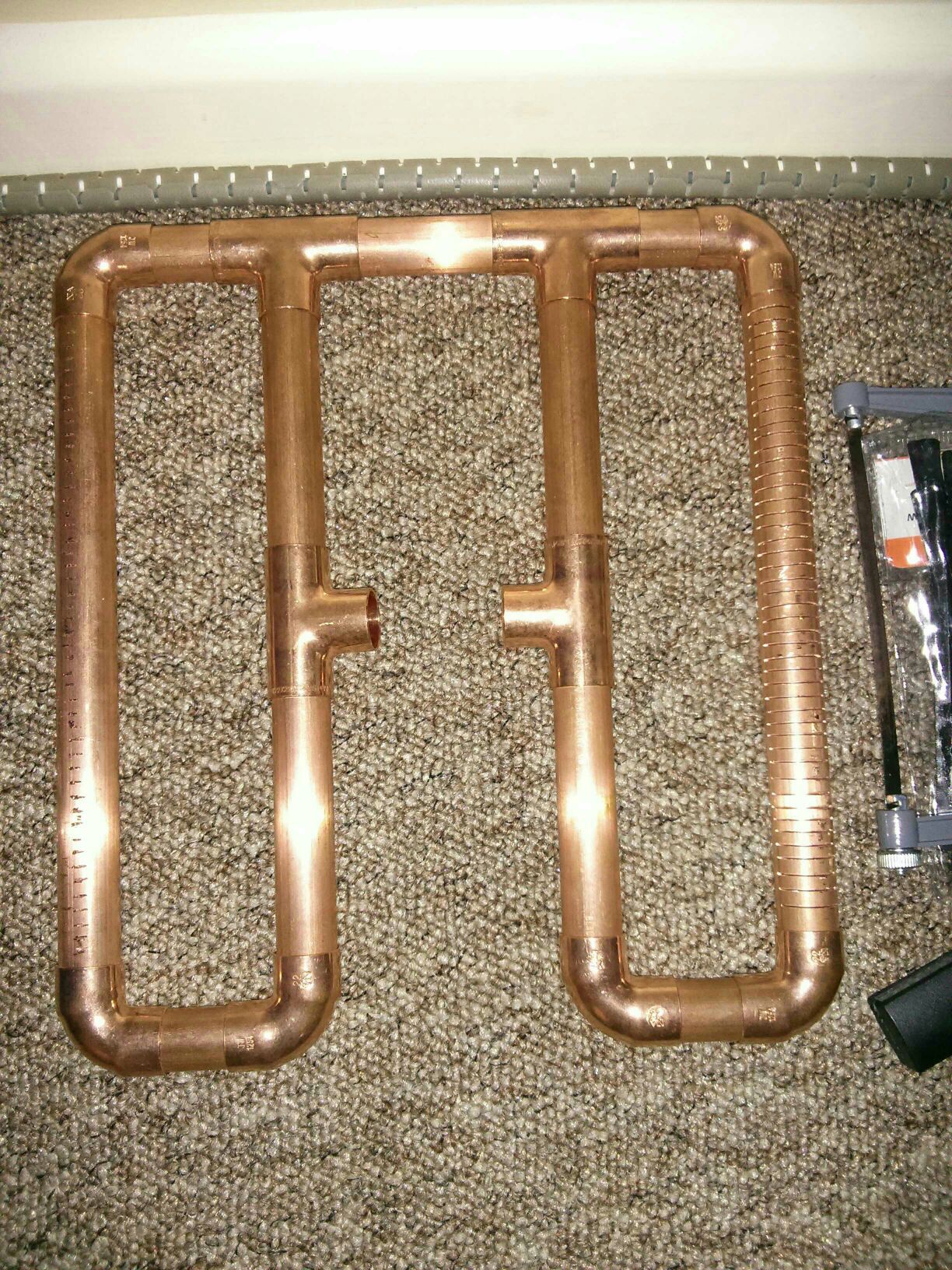

I'm planning on going for a DIY job copper manifold which will hopefully just slot into the back of the tank connector and out again after use for cleaning.

Let me know your ideas/thoughts.

Cheers guys!

I've just purchased 1 of these today

http://www.caravantech-shop.co.uk/produ ... 8-cool-box

And also this tank connector which is already drilled out to accept 15mm copper pipe

http://www.copperkettlehomebrewing.co.u ... -connector

Just a couple of questions regarding the installation of a ball valve tap....

I'm planning on installing the tank connector with the threaded end on the outside of the coolbox and the flat end on the inside with the rubber washer sealing against the inside face of the box.

After tightening this up I'm then planning to screw a 1/2 inch 2 piece ball valve tap onto the threads of the tank connector on the outside with PTFE tap to seal the threads.

This is the tap I'm talking about

http://www.themaltmiller.co.uk/index.ph ... ductId=411

Its a female 1/2" on both ends

Would this setup work OK with this particular coolbox? I've seen some other threads but its never very clear how people are hooking the taps up.

I'm planning on going for a DIY job copper manifold which will hopefully just slot into the back of the tank connector and out again after use for cleaning.

Let me know your ideas/thoughts.

Cheers guys!