Bru4u

Landlord.

After chatting in the errrr chat room a few chaps were interested in my set up so I decided to share it on here with you all.

I had been a while collecting suitable tanks and old kegs to use, I was then left with this.

Every Brewery need a dog, these are my girls

The two tanks are 100 ltr and are both jacketed, this meant I could control the temp of what ever is inside without contact with the heating element, so I decided the tall one would be the primary fermenter and the wide one would be the mash tun, I could join two 50ltr kegs for both the HLT and the kettle which would be gas heated.

I did not fancy a gravity tower system as it would have been too high and a pain to use so it was going to be herms, a frame had to be designed and built from 30mm box and 125mm castors.I cut the tops of the kegs and welded two together then made an opening in one end and used one of the old tops to make a lid.

So the frame together and all tanks fitting, time for the Jacket water heating systems. The MT and FV are seperate systems but joined to a common expansion tank, drain and relief valve. They each have a domestic heating circ pump and a heat exchanger, I got three immersion elements and inserted into 5" steel pipe on ends I machined up. So the system goes.

Pump - - Heat Exchanger- - Vessel - - Back to pump.

I did not matter that there was a mix of materials as there would be a corrosion inhibitor in the heating water, with the heating system plumbed up I found major cracks in the outside jacket of the MT so there was about Half a day with the Tig sorting that.

Next I needed a way to transfer the liquer and wort around, after reading Vossy's article on pumps I went for a pair of march may pumps, because the system is big I used 3/4" valves and fittings, this would make washing down easier later on but makes no difference to the brewing as you only pump at a slow rated when brewing, there was no fitting on the MT so I had to design, program and make one on the CNC Lathe, I got high temp food grade flex piping locally, again 3/4".

.

.

The HLT and Kettle are gas fired and needed plumbing to it. The kettle is manually controlled coz all you need to do is get it boiling and hold it there but I needed control over the HLT, so I fitted a solenoid valve before the burner to the HLT.

I had to make a false bottom for the MT and had some stainless perforated sheet in 2mm but the holes were too big so I got some fine mesh to go over and also made a suction filter for the kettle with the mesh.

The FV came with with out a lid so one had to be made, I just used overcenter clamps to secure it and dairy tube joined to make a giant O-Ring, I cut the lid and made a hole for the airlock in the CNC Plasma at work.

Time for some control and lots of electric string, three PID's and two pumps, the switches allow me to monitor temp without the circ pump or elements on and same for the HLT. SSR's heat sinks and other gubbins in the box.

I think thats the build complete and looking like this, there was a bit more to it but I'd bore you all to death.

The first Brew.

now there was no way I was going crushing 12Kg of malt with a rolling pin so I found this

I get the malt directly from the malting company in bulk, a large wheelie bin or two.

I just did 40ltr to get to know the system a bit.

Crushing the grains

Mashing in

Sparging with the spinny thing

Temp Control

Into the kettle for a boil

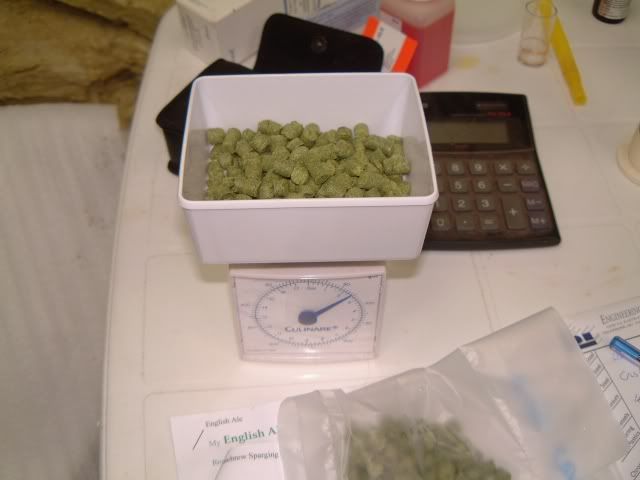

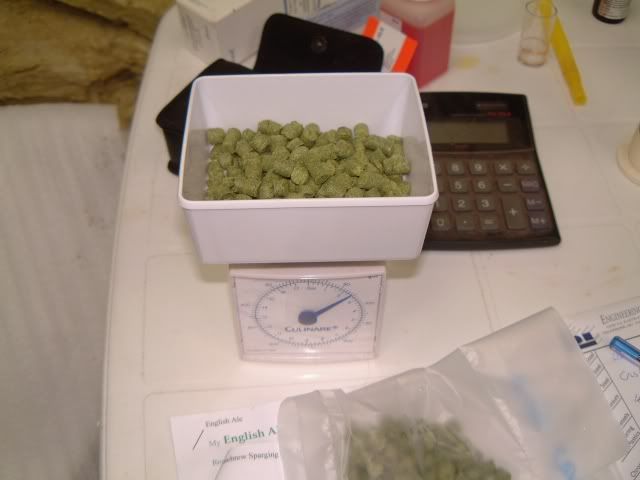

Meanwhile hops weighed out

And Yeast running starter made up

Into the FV and temp set, bubbling in no time and time to clean up

Well I hope you enjoyed it as much as I did and still do, I normally do 50 ltr in a new beer and 80ltr for things I like, I done about 10 brews with it now, there was a lot of reading and researching, I'd done about 20 kits on and off over about 10 yrs and decided to get serious about it, If your still on kits, give AG a lash, the quality of beer is unreal.

I am an Engineer and co own this company Mid Cork Metalworks Ltd so it made things easier for me.

The one thing I'd like to say is that it's not the equipment that makes good beer but the person behind it, this setup just makes life easier for me.

I had been a while collecting suitable tanks and old kegs to use, I was then left with this.

Every Brewery need a dog, these are my girls

The two tanks are 100 ltr and are both jacketed, this meant I could control the temp of what ever is inside without contact with the heating element, so I decided the tall one would be the primary fermenter and the wide one would be the mash tun, I could join two 50ltr kegs for both the HLT and the kettle which would be gas heated.

I did not fancy a gravity tower system as it would have been too high and a pain to use so it was going to be herms, a frame had to be designed and built from 30mm box and 125mm castors.I cut the tops of the kegs and welded two together then made an opening in one end and used one of the old tops to make a lid.

So the frame together and all tanks fitting, time for the Jacket water heating systems. The MT and FV are seperate systems but joined to a common expansion tank, drain and relief valve. They each have a domestic heating circ pump and a heat exchanger, I got three immersion elements and inserted into 5" steel pipe on ends I machined up. So the system goes.

Pump - - Heat Exchanger- - Vessel - - Back to pump.

I did not matter that there was a mix of materials as there would be a corrosion inhibitor in the heating water, with the heating system plumbed up I found major cracks in the outside jacket of the MT so there was about Half a day with the Tig sorting that.

Next I needed a way to transfer the liquer and wort around, after reading Vossy's article on pumps I went for a pair of march may pumps, because the system is big I used 3/4" valves and fittings, this would make washing down easier later on but makes no difference to the brewing as you only pump at a slow rated when brewing, there was no fitting on the MT so I had to design, program and make one on the CNC Lathe, I got high temp food grade flex piping locally, again 3/4".

The HLT and Kettle are gas fired and needed plumbing to it. The kettle is manually controlled coz all you need to do is get it boiling and hold it there but I needed control over the HLT, so I fitted a solenoid valve before the burner to the HLT.

I had to make a false bottom for the MT and had some stainless perforated sheet in 2mm but the holes were too big so I got some fine mesh to go over and also made a suction filter for the kettle with the mesh.

The FV came with with out a lid so one had to be made, I just used overcenter clamps to secure it and dairy tube joined to make a giant O-Ring, I cut the lid and made a hole for the airlock in the CNC Plasma at work.

Time for some control and lots of electric string, three PID's and two pumps, the switches allow me to monitor temp without the circ pump or elements on and same for the HLT. SSR's heat sinks and other gubbins in the box.

I think thats the build complete and looking like this, there was a bit more to it but I'd bore you all to death.

The first Brew.

now there was no way I was going crushing 12Kg of malt with a rolling pin so I found this

I get the malt directly from the malting company in bulk, a large wheelie bin or two.

I just did 40ltr to get to know the system a bit.

Crushing the grains

Mashing in

Sparging with the spinny thing

Temp Control

Into the kettle for a boil

Meanwhile hops weighed out

And Yeast running starter made up

Into the FV and temp set, bubbling in no time and time to clean up

Well I hope you enjoyed it as much as I did and still do, I normally do 50 ltr in a new beer and 80ltr for things I like, I done about 10 brews with it now, there was a lot of reading and researching, I'd done about 20 kits on and off over about 10 yrs and decided to get serious about it, If your still on kits, give AG a lash, the quality of beer is unreal.

I am an Engineer and co own this company Mid Cork Metalworks Ltd so it made things easier for me.

The one thing I'd like to say is that it's not the equipment that makes good beer but the person behind it, this setup just makes life easier for me.