- Joined

- Oct 17, 2011

- Messages

- 4,116

- Reaction score

- 984

Is it possible?

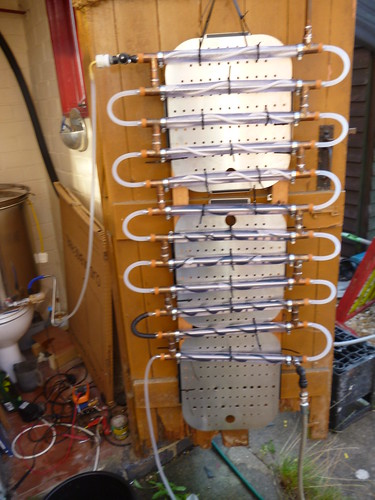

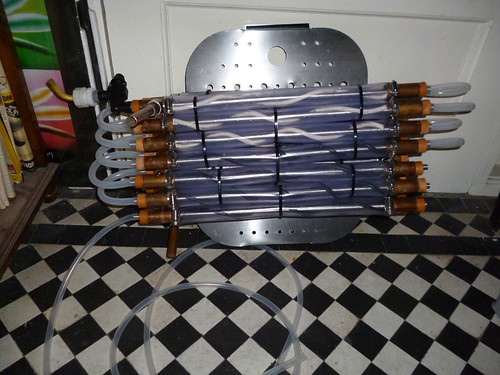

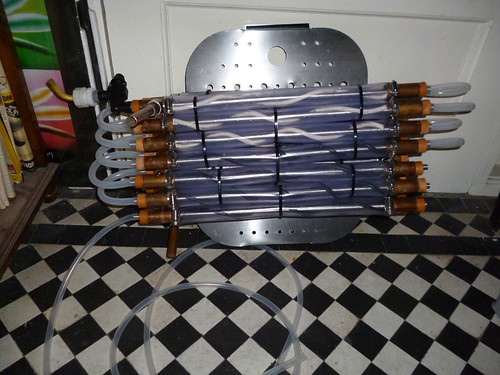

i followed a hunch and built a cfc i could clean the inside of the beer transport tubes with a brush easily..

the initial plan was to use it to recirculate back into the boiler and try to encourage a whirlpool to deposit the cold break centrally before draining clear of as much break material as possible into the FV.

however after initial testing it appears its efficient enough to use in a singe pass thu straight to the FV.

:)

SO if possible i would like to filter out the break material that should be in suspension and not trapped in any nooks in my chiller

I currently fill my fvs post IC chilling thru a nylon sieve to oxygenate but that doesent filter anything so still get inches of cold break trub settling?

i followed a hunch and built a cfc i could clean the inside of the beer transport tubes with a brush easily..

the initial plan was to use it to recirculate back into the boiler and try to encourage a whirlpool to deposit the cold break centrally before draining clear of as much break material as possible into the FV.

however after initial testing it appears its efficient enough to use in a singe pass thu straight to the FV.

:)

SO if possible i would like to filter out the break material that should be in suspension and not trapped in any nooks in my chiller

I currently fill my fvs post IC chilling thru a nylon sieve to oxygenate but that doesent filter anything so still get inches of cold break trub settling?