unclepumble

Landlord.

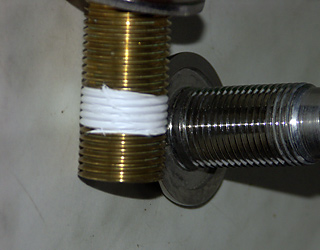

Now then Tony that is a stroke of genius, and should be very pellet friendly too.

Let us know how it works on your next brew.

UP

Let us know how it works on your next brew.

UP

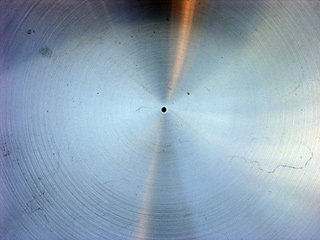

I bet you don't drop yours and ding the base like I did though :evil: :evil:Runwell-Steve said:I bet the end result isn't as smart as yours though.

Aleman said:I bet you don't drop yours and ding the base like I did though :evil: :evil:Runwell-Steve said:I bet the end result isn't as smart as yours though.

Aleman said:

Aleman said:ericstd said:Why "pico and nano"?

One being 10 to the power -12 and the other 10 to the power -9!! :whistle:

Well can't really call anything less than 1BBL (164L) a Microbrewery . . . My previous setup could safely produce 60L so I called it a pico brewery . . . . this is bigger (probably max boil of 150L . . . still not 1BBL so still not a micro) . . . and so Nano . . . not strictly SI :lol:

And the 20L plant is a femtobrewery . . . . . I'm waiting for someone to produce a 1L all grain system to claim the yocto prefix :lol: :lol:

Well done Dennis, that's the first time that name has ever come back to haunt me!dennisdk2000 said:ericstd said:Why "pico and nano"?

One being 10 to the power -12 and the other 10 to the power -9!! :whistle: