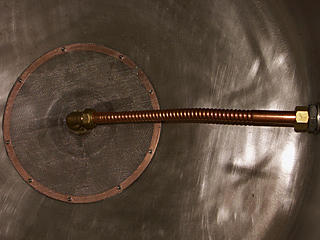

Well it's now happening, finally decided to put things together . . . you remember this

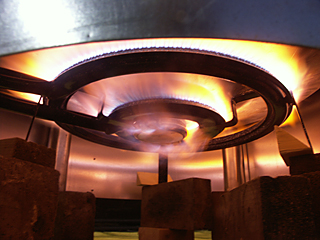

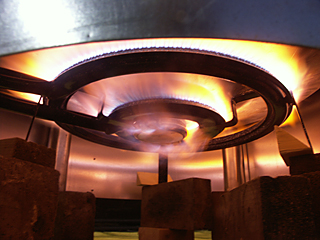

Well this is it in the dark with the shroud fitted and the burner doing it's stuff

And the good news is that at 37mBar . . . it took 40L or water from 25C to 78C in 25 minutes . . . which is pretty much better than the picocopper could manage (I have an email from Hamilton gas that says it will take hours to get a large volume of water to boiling) so I'm quite pleased . . .as it means that I will be saving gas.

Bidding on some big casters that will screw into the legs so that I can move it about.

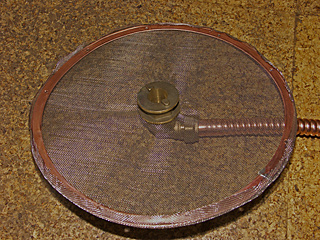

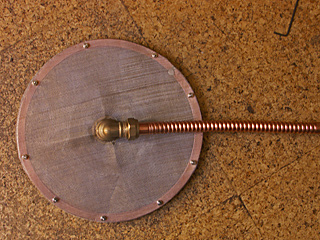

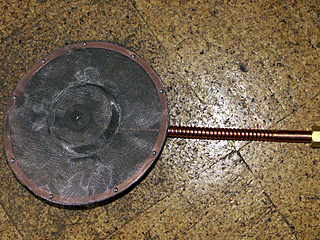

As there is not really any way to put an immersion chiller inside (well a very skinny one perhaps) I am going to have to get the plate chiller sorted as well. . . . And I suppose I'll need the spinney sparger as well . . . too much to do and not enough time to do it

Can't wait for the first brewing session now :party: :party:

Well this is it in the dark with the shroud fitted and the burner doing it's stuff

And the good news is that at 37mBar . . . it took 40L or water from 25C to 78C in 25 minutes . . . which is pretty much better than the picocopper could manage (I have an email from Hamilton gas that says it will take hours to get a large volume of water to boiling) so I'm quite pleased . . .as it means that I will be saving gas.

Bidding on some big casters that will screw into the legs so that I can move it about.

As there is not really any way to put an immersion chiller inside (well a very skinny one perhaps) I am going to have to get the plate chiller sorted as well. . . . And I suppose I'll need the spinney sparger as well . . . too much to do and not enough time to do it

Can't wait for the first brewing session now :party: :party:

![BREWING THERMOMETER STICKERS ACCURATELY MONITOR FERMENTING BEER & WINE LIQUID TEMPERATURES 5PCS HOME BREW SPIRITS WINE LCD ADHESIVE [US]](https://m.media-amazon.com/images/I/311DDjo2X3L._SL500_.jpg)