HisDudeness

Active Member

- Joined

- Apr 16, 2015

- Messages

- 94

- Reaction score

- 412

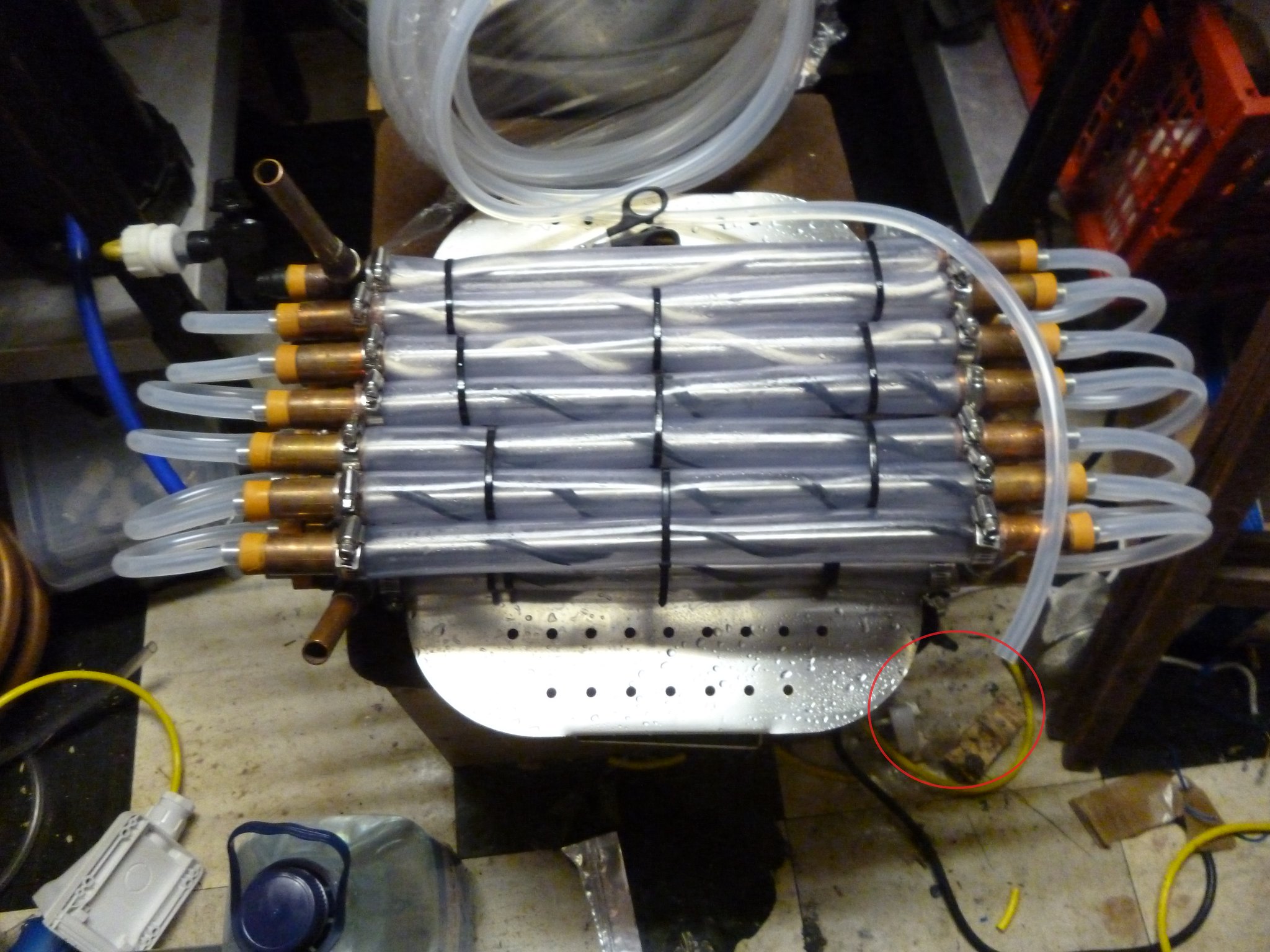

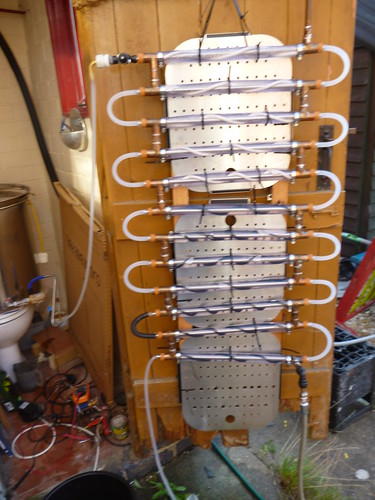

I have one (home made). The spiral around the inside isnt to impede the waterflow, but to make it flow around the pipe, thus increasing the cooling effect. I can drop my wort to pitching temp and fill my fv in about twenty minutes, all on gravity/waterflow. Brilliant bit of kit. To clean, I flush with a kettle of boiling water straight after use, then again before its next use, plus a flush through with starsan.

Thanks Manse. :thumb:

What length of hose/pipe would you think best for this type of chiller working with batches no bigger than 23L? What are your thoughts on using 8mm pipe as mentioned above?