My chinese boiler kept cutting out at the end of a 60 min boil I assume its a thermal over-ride causing the problem. The temps are controlled by a thermostat knob on the side. I want to see if I can disable top top temp cutout in some way but keep contol of the temps ( hope you understood that.

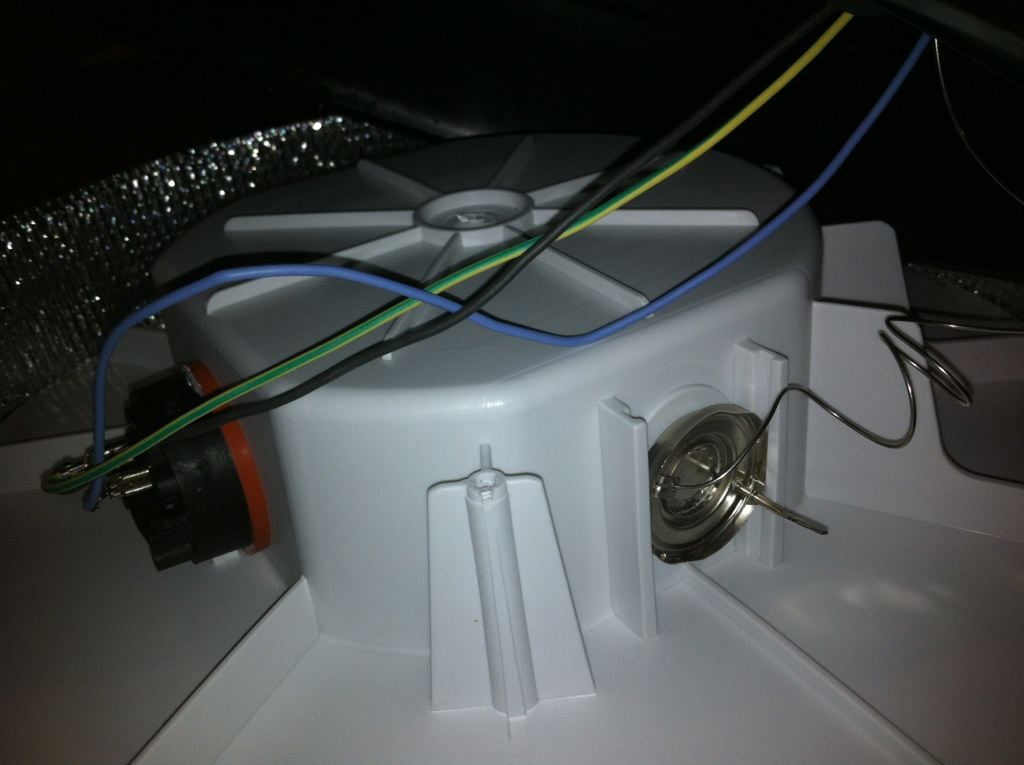

heres a pic of the gubbins. can anyone tell me where the temp overide disc /switch or whatever is...

pic 2

thanks in advance

heres a pic of the gubbins. can anyone tell me where the temp overide disc /switch or whatever is...

pic 2

thanks in advance