darthballs

Member

24 Sep 2012

My first AG brew started well albeit quite late in the day at 1600, I sorted out all of the grains and poured them into a clean dry FV so that I could mix them up before putting them into the mash.

I then put 37 litres of liquor (with 1 campden tablet already crushed into it) into the boiler and started it up.

*Lesson 1 learned here, get your liquor sorted first and start the boiler before you do anything else as it's a long wait for the water to heat up!

Once the boiler reached it's temp I took a temp reading 75 degrees, which is what I wanted and I measured 20 litres into the mashtun, using a measuring jug (*Lesson 2, get a bigger measuring jug, 2 litres at a time was a pain)

I then checked the temp still 73 degrees so began slowly measuring the grain into the mashtun, until the FV was light enough to lift and then poured the remainder in, then I gave it a stir to make sure all of the grain was covered and in the hot liqour and took another temp reading, 65 degrees perfect! I closed the lid, wrapped a blanket around the coolbox and set an alarm on my phone for 90 minutes.

Then helped the other half finish cleaning the car.

85 minutes later, I switch the boiler back on.

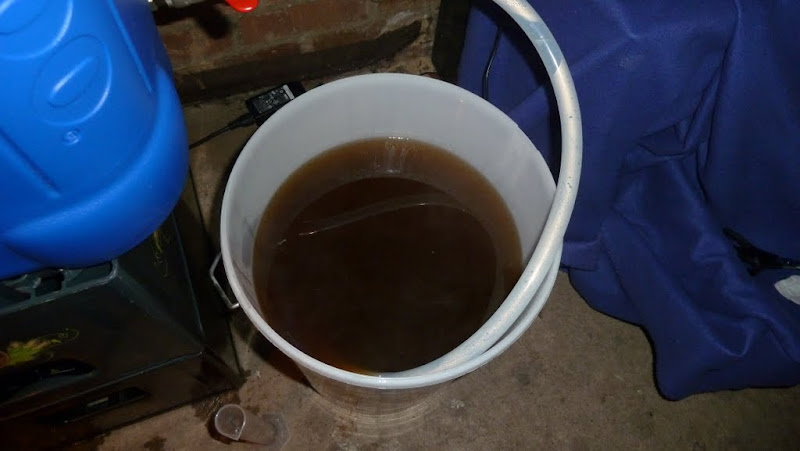

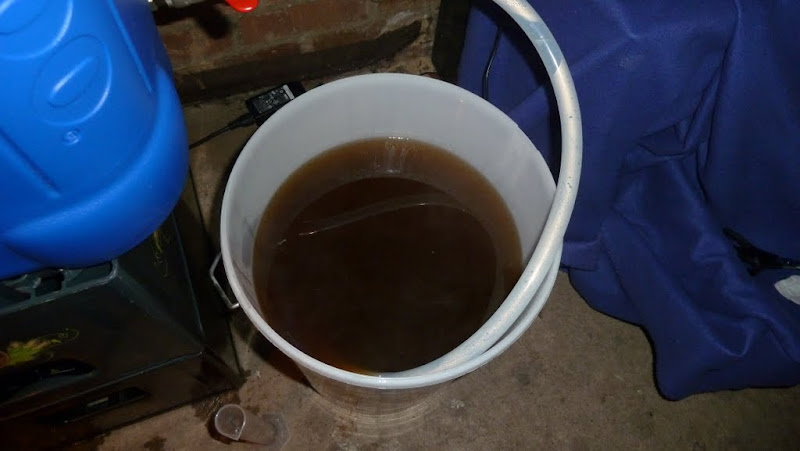

5 mins later I switched off the alarm. I had to raise the mashtun up a little as it was too low to drain into my fermenting bin so I used two beer crates one of top of the other and then placed the mashtun on top of this, quite carefully as I was concerned about it falling over and spilling everywhere. Once happy I then opened the mashtun and took another reading 64 degrees I was pleased with that so proceeded to collecting the wort, Beersmith said I needed a little over 29 litres of wort for the 23 I was aiming for.

I placed a piece of tin foil over the grain bed after poking 40 or 50 little holes in it with the sharp end of my temp gauge. Took the jug I used to fill the mashtun with and slowly opened the tap to draw out the first runnings, these were a little cloudy with bits in but this was expected so after a few litres of this they became clear and I double checked this (doing it twice) to check for bits in the liquid, they were clear.

I placed my fermenting bin under the mashtun and opened the tap to the same speed as before and at the same time I filled the water jug with water from the boiler and slowly poured this over the top of the grain bed to make a thin layer of water on top of the tin foil, this process continued for quite a while until I had gathered about 12-13 litres and I then turned off the tap and checked the SG, the first test was pretty high at about 1.068 so I just resumed the process for a while longer until I reach about 16/17 litres and then checked again the SG was still high around the 1.054 mark so I went to resume, but, oops! I had forgotten to top up the boiler and had almost run out of hot water, had about 2 or 3 litres left in the tank, so I panicked and filled about 10-15 litres straight into the boiler (untreated) from my hose (which was bought just for my water needs for brewing) and switched it onto full boil. I also rushed upstairs to get a kettle full of water too but I eventually realised I had to stop collecting whilst the water boiled and this made me panic some more so I started looking up various how to's looking for tips and to try and calm me down a bit.

Once the water had boiled, I resumed collecting but eventually overshot my wort amount, as I confused myself and I kept checking for the SG to fall to 0.990 (after mis-reading a how to guide about a totally different brew) but it wouldn't drop below 1.000 but at 1.000 I stopped after collecting what looked well over 30 litres. (Lesson: Don't collect more wort than I need, If I want to collect more wort for a double brew weaker brew, I can but next time I will stick exactly to my liquor amounts)

I decided to stop here regardless and emptied the boiler of any remaining water. I then put all of the wort into the boiler and when finished could see it was about 35 litres, waaaaaaaay over what I needed! Regardless I ploughed on and took a reading and it said 1046 SG.

Once all the wort was in, I switched the boiler on and waited for it to boil. It took an age to get up to boiling mainly because I had collected too much. Once a rolling boil was reached I put the first stage of hops and the homemade candi sugar in and set a timer for 30 mins, then again the second stage hops went in with a 15 min timer and then a 10 min timer with the 15 min hops and the wort chiller and finally the 5 min hops, coriander seed and seeds of paradise for the last 5 mins. By the time the boil had finished it was about 2230-2245 and I was getting pretty weary by now.

I also realised I had forgotten to put in my 1/4 protofloc tablet in (with 15 mins to go) so added this just after I had started to chill the wort, I figured better late than never. Lesson: get your ingredients ALL ready because I had these separate from the hops so next time I won't...

Chill time, on went the hoses outside the boiler and I turned on the water at the tap, this took an age to get a decent flow and seems to be a bit of a trial and error process which might take several goes until I master it. I think mainly because I had 15 metres of pipe from the tap to the chiller I suspect this held up the flow, also the connector for the outflow from the chiller was a bit of a bodge job as I stupidly (but too late to worry about it then) didn't have enough Hozelock connectors. Lesson: have the right equipment beforehand.

After about 15 mins my bodge job with the connectors didn't hold and the pipes violently came apart, luckily this all missed me and was way outside the boiler so no leaking was possible. I quickly used one of the FVs that had been used to collect the wort to catch the very hot water and just shuttled between the two bins back and forth to the drain until I got the temp down to just under 30 degrees. The time was about 2330 now and I was exhausted but couldn't stop now. I then slowly (at first) drained the wort from the boiler through a sieve to collect any bits that flowed through, this soon stopped as the hop strainer kicked in and the flow became clear.

The FV was very full about 28 litres collected. I took a reading and it was 1.060 which I think equates to about 6.0 abv, much reduced from the forecasted 1.081. I then struggled upstairs with the FV to the kitchen and placed it on our beer fridge and aerated it for a good 3 or 4 mins. Took another temp reading and it was 24 degrees which was good enough for me so I shook up my white labs yeast and pitched it into the FV, gave it one final stir and snapped the lid shut and put the air lock on and went to bed.

When I got home last night I had to do the clean up as I had just left everything in the garage. This was a pain for the boiler and I have not finished cleaning the burnt wort off of where the element sits. I will finish this with some lemon juice before my next brew.

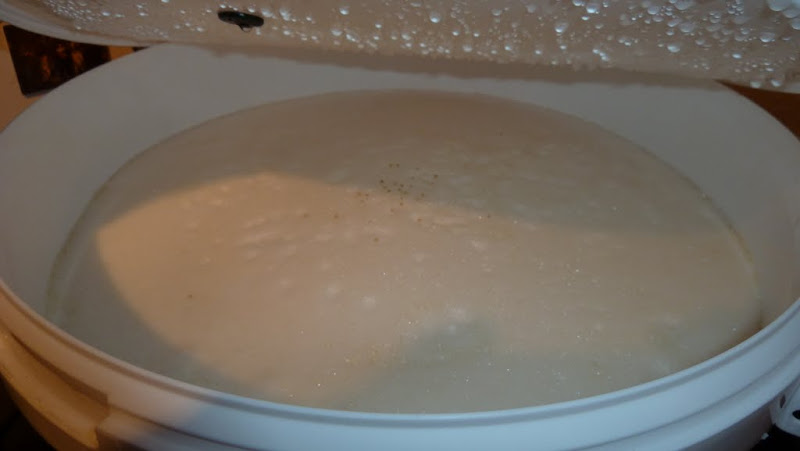

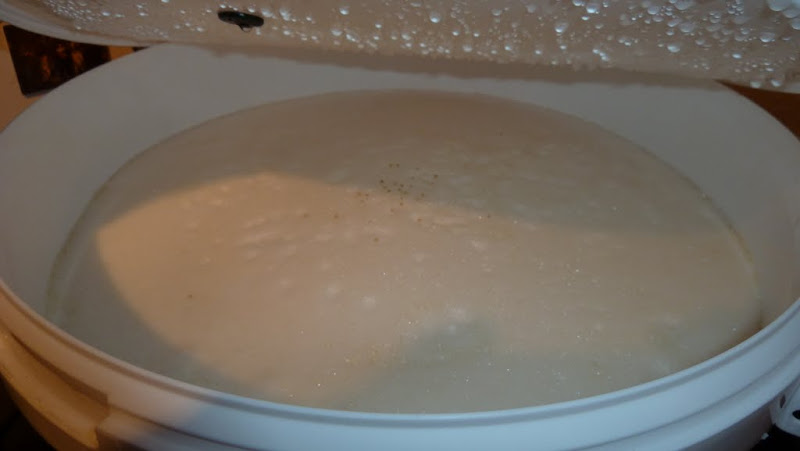

I also checked the FV and a lovely krausen had formed on the surface, I will leave this now until at least the weekend before checking it again but it smells gorgeous so far.

:)

My first AG brew started well albeit quite late in the day at 1600, I sorted out all of the grains and poured them into a clean dry FV so that I could mix them up before putting them into the mash.

I then put 37 litres of liquor (with 1 campden tablet already crushed into it) into the boiler and started it up.

*Lesson 1 learned here, get your liquor sorted first and start the boiler before you do anything else as it's a long wait for the water to heat up!

Once the boiler reached it's temp I took a temp reading 75 degrees, which is what I wanted and I measured 20 litres into the mashtun, using a measuring jug (*Lesson 2, get a bigger measuring jug, 2 litres at a time was a pain)

I then checked the temp still 73 degrees so began slowly measuring the grain into the mashtun, until the FV was light enough to lift and then poured the remainder in, then I gave it a stir to make sure all of the grain was covered and in the hot liqour and took another temp reading, 65 degrees perfect! I closed the lid, wrapped a blanket around the coolbox and set an alarm on my phone for 90 minutes.

Then helped the other half finish cleaning the car.

85 minutes later, I switch the boiler back on.

5 mins later I switched off the alarm. I had to raise the mashtun up a little as it was too low to drain into my fermenting bin so I used two beer crates one of top of the other and then placed the mashtun on top of this, quite carefully as I was concerned about it falling over and spilling everywhere. Once happy I then opened the mashtun and took another reading 64 degrees I was pleased with that so proceeded to collecting the wort, Beersmith said I needed a little over 29 litres of wort for the 23 I was aiming for.

I placed a piece of tin foil over the grain bed after poking 40 or 50 little holes in it with the sharp end of my temp gauge. Took the jug I used to fill the mashtun with and slowly opened the tap to draw out the first runnings, these were a little cloudy with bits in but this was expected so after a few litres of this they became clear and I double checked this (doing it twice) to check for bits in the liquid, they were clear.

I placed my fermenting bin under the mashtun and opened the tap to the same speed as before and at the same time I filled the water jug with water from the boiler and slowly poured this over the top of the grain bed to make a thin layer of water on top of the tin foil, this process continued for quite a while until I had gathered about 12-13 litres and I then turned off the tap and checked the SG, the first test was pretty high at about 1.068 so I just resumed the process for a while longer until I reach about 16/17 litres and then checked again the SG was still high around the 1.054 mark so I went to resume, but, oops! I had forgotten to top up the boiler and had almost run out of hot water, had about 2 or 3 litres left in the tank, so I panicked and filled about 10-15 litres straight into the boiler (untreated) from my hose (which was bought just for my water needs for brewing) and switched it onto full boil. I also rushed upstairs to get a kettle full of water too but I eventually realised I had to stop collecting whilst the water boiled and this made me panic some more so I started looking up various how to's looking for tips and to try and calm me down a bit.

Once the water had boiled, I resumed collecting but eventually overshot my wort amount, as I confused myself and I kept checking for the SG to fall to 0.990 (after mis-reading a how to guide about a totally different brew) but it wouldn't drop below 1.000 but at 1.000 I stopped after collecting what looked well over 30 litres. (Lesson: Don't collect more wort than I need, If I want to collect more wort for a double brew weaker brew, I can but next time I will stick exactly to my liquor amounts)

I decided to stop here regardless and emptied the boiler of any remaining water. I then put all of the wort into the boiler and when finished could see it was about 35 litres, waaaaaaaay over what I needed! Regardless I ploughed on and took a reading and it said 1046 SG.

Once all the wort was in, I switched the boiler on and waited for it to boil. It took an age to get up to boiling mainly because I had collected too much. Once a rolling boil was reached I put the first stage of hops and the homemade candi sugar in and set a timer for 30 mins, then again the second stage hops went in with a 15 min timer and then a 10 min timer with the 15 min hops and the wort chiller and finally the 5 min hops, coriander seed and seeds of paradise for the last 5 mins. By the time the boil had finished it was about 2230-2245 and I was getting pretty weary by now.

I also realised I had forgotten to put in my 1/4 protofloc tablet in (with 15 mins to go) so added this just after I had started to chill the wort, I figured better late than never. Lesson: get your ingredients ALL ready because I had these separate from the hops so next time I won't...

Chill time, on went the hoses outside the boiler and I turned on the water at the tap, this took an age to get a decent flow and seems to be a bit of a trial and error process which might take several goes until I master it. I think mainly because I had 15 metres of pipe from the tap to the chiller I suspect this held up the flow, also the connector for the outflow from the chiller was a bit of a bodge job as I stupidly (but too late to worry about it then) didn't have enough Hozelock connectors. Lesson: have the right equipment beforehand.

After about 15 mins my bodge job with the connectors didn't hold and the pipes violently came apart, luckily this all missed me and was way outside the boiler so no leaking was possible. I quickly used one of the FVs that had been used to collect the wort to catch the very hot water and just shuttled between the two bins back and forth to the drain until I got the temp down to just under 30 degrees. The time was about 2330 now and I was exhausted but couldn't stop now. I then slowly (at first) drained the wort from the boiler through a sieve to collect any bits that flowed through, this soon stopped as the hop strainer kicked in and the flow became clear.

The FV was very full about 28 litres collected. I took a reading and it was 1.060 which I think equates to about 6.0 abv, much reduced from the forecasted 1.081. I then struggled upstairs with the FV to the kitchen and placed it on our beer fridge and aerated it for a good 3 or 4 mins. Took another temp reading and it was 24 degrees which was good enough for me so I shook up my white labs yeast and pitched it into the FV, gave it one final stir and snapped the lid shut and put the air lock on and went to bed.

When I got home last night I had to do the clean up as I had just left everything in the garage. This was a pain for the boiler and I have not finished cleaning the burnt wort off of where the element sits. I will finish this with some lemon juice before my next brew.

I also checked the FV and a lovely krausen had formed on the surface, I will leave this now until at least the weekend before checking it again but it smells gorgeous so far.

:)

![BREWING THERMOMETER STICKERS ACCURATELY MONITOR FERMENTING BEER & WINE LIQUID TEMPERATURES 5PCS HOME BREW SPIRITS WINE LCD ADHESIVE [US]](https://m.media-amazon.com/images/I/311DDjo2X3L._SL500_.jpg)