tubby_shaw

Regular.

- Joined

- Feb 7, 2009

- Messages

- 387

- Reaction score

- 15

Two can or all malt beer kits are the pinnacle of beer kit brewing, these kits are available in a wide range of beer styles and are the best that can be experienced in home brewing before taking up extract or grain brewing.

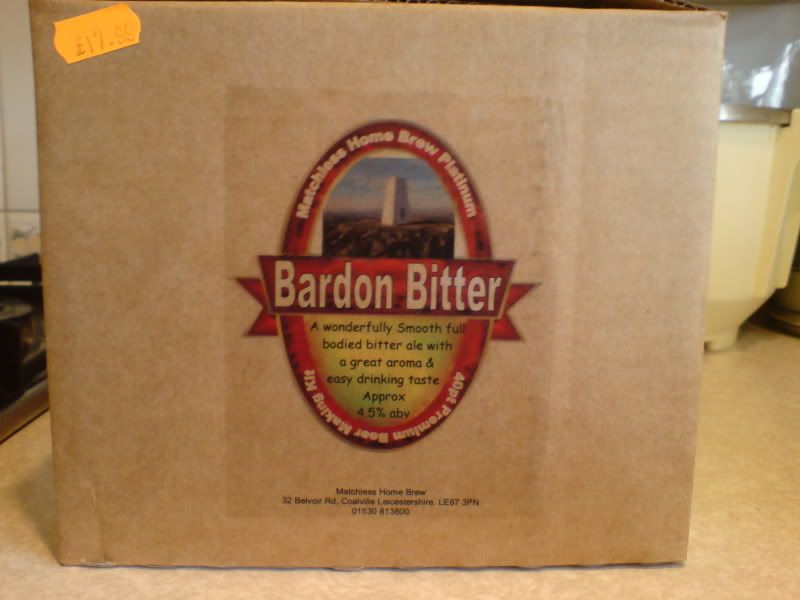

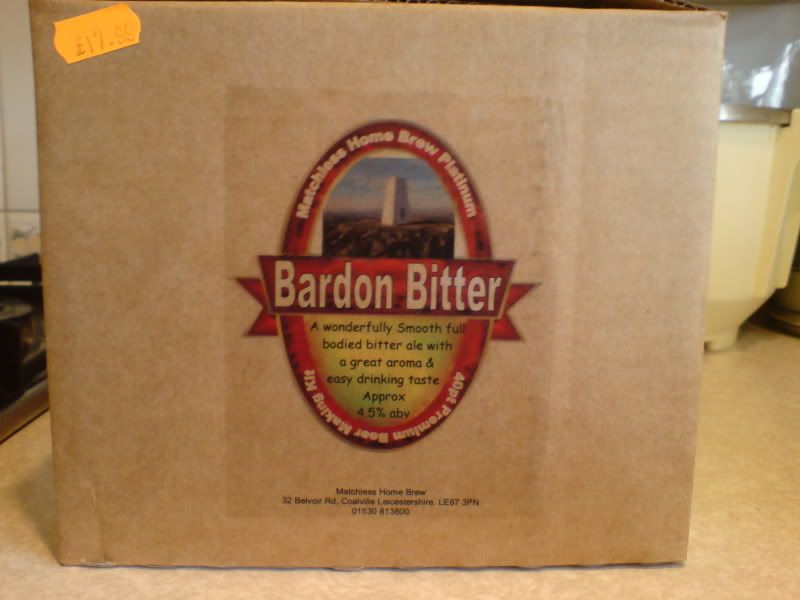

This kit is Bardon bitter from Matchless Homebrew

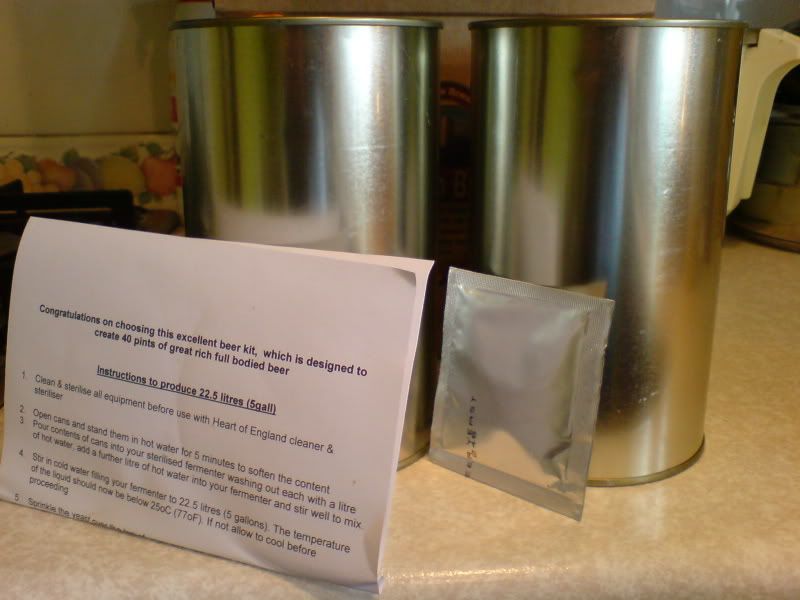

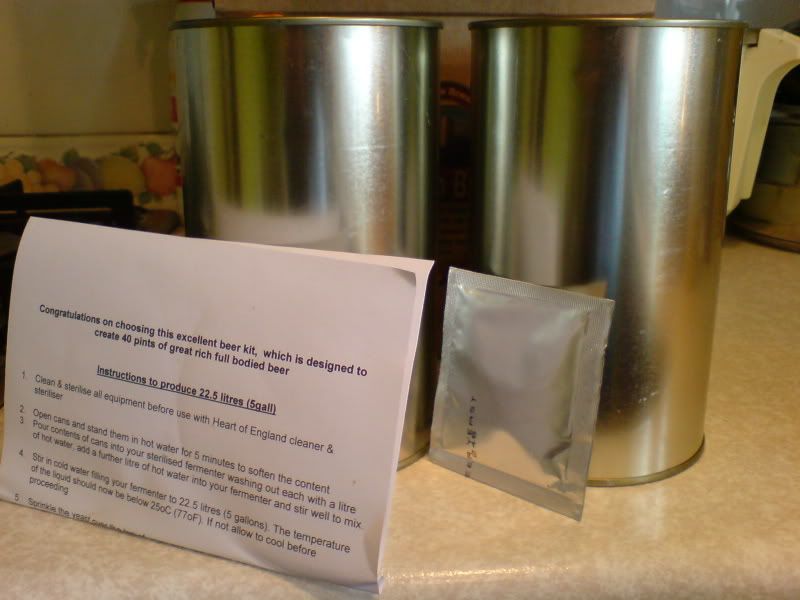

The kit contents, two cans of hopped malt extract, comprehensive instructions and a sachet of yeast.

Recommended equipment is two 30l fermentation buckets with lids and taps, your choice of sanitising solution, a kettle, thermometer, hydrometer and trial jar and campden tablets or campden powder.

The first stage of the process is to clean and sanitise the fermentation buckets.

My recommendation before doing anything further is to dechlorinate your brewing water. Using 1/2 a crushed campden tablet or the equivalent of campden powder stirred into 25L of tap water will immediately remove all chlorine and chloramines.

Adding the campden powder to the tap water

Take the water required to be heated from the treated water and boil it in your kettle.

Standing the two cans in hot water for 5 minutes prior to opening will soften the contents and make them easier to work with. Make sure to use a clean can opener.

The two opened cans.

Empty the can contents into the fermenting vessel.

Use some of the boiled treated water to rinse out all of the can contents.

Empty the dissolved contents of the cans into the fermenting vessel.

Warning the can will be very hot, use oven gloves or similar to protect your hands!

Stir to dissolve the bulk of the malt extract in the hot water added from the can.

Using the tap on the bucket containing your treated water, drop your treated water into the dissolved kit contents. This will ensure thorough mixing and also aerate your wort to give the yeast the best possible start.

Check that the temperature of your wort is between 20 and 28 Celsius

If the temperature is correct add the yeast.

Take a gravity reading. In this case 1.040. If you plan to return the sample to the fermenter make sure that the hydrometer and trial jar were sanitised.

22.5 Litres of Bardon bitter waiting for the yeasties to do their thing.

18 hours later at 20C and the yeast crop is beginning to form nicely

28 hours in and the yeast head looks like this.

7 days later and fermentation is finished

This is how it looks after a week, after another 3 days, it'll clear down considerably and be ready for kegging.

OK so it's been 8 days, gravity is 1.012, but now it's time to keg.

I will be using a plastic home brew keg for this how to.

The keg was cleaned with Oxyclean, then sanitised with a solution of cheap, thin, unscented bleach. Then rinsed well with cold tap water and finally swilled out with a kettle of boiling water. (Be careful)

50g of sugar (I used demerera, but use what you prefer) was weighed out.

The sugar was added to the keg.

Using a length of hose from the tap on the fermenter, the beer was run into the keg which mixed in the sugar.

Once all the beer was in the keg a burst of gas from an S30 cylinder was added.

After 5 minutes to allow the CO2 to settle, the lid was cracked to vent the air in the keg and leave a protective blanket of CO2.

This keg has a mechanical pressure relief valve, a further squirt of gas and the indicator can be seen to be OK (Green showing)

40 Pints of Bardon bitter conditioning.

I'll give it a couple of weeks before checking for clarity.

This kit is Bardon bitter from Matchless Homebrew

The kit contents, two cans of hopped malt extract, comprehensive instructions and a sachet of yeast.

Recommended equipment is two 30l fermentation buckets with lids and taps, your choice of sanitising solution, a kettle, thermometer, hydrometer and trial jar and campden tablets or campden powder.

The first stage of the process is to clean and sanitise the fermentation buckets.

My recommendation before doing anything further is to dechlorinate your brewing water. Using 1/2 a crushed campden tablet or the equivalent of campden powder stirred into 25L of tap water will immediately remove all chlorine and chloramines.

Adding the campden powder to the tap water

Take the water required to be heated from the treated water and boil it in your kettle.

Standing the two cans in hot water for 5 minutes prior to opening will soften the contents and make them easier to work with. Make sure to use a clean can opener.

The two opened cans.

Empty the can contents into the fermenting vessel.

Use some of the boiled treated water to rinse out all of the can contents.

Empty the dissolved contents of the cans into the fermenting vessel.

Warning the can will be very hot, use oven gloves or similar to protect your hands!

Stir to dissolve the bulk of the malt extract in the hot water added from the can.

Using the tap on the bucket containing your treated water, drop your treated water into the dissolved kit contents. This will ensure thorough mixing and also aerate your wort to give the yeast the best possible start.

Check that the temperature of your wort is between 20 and 28 Celsius

If the temperature is correct add the yeast.

Take a gravity reading. In this case 1.040. If you plan to return the sample to the fermenter make sure that the hydrometer and trial jar were sanitised.

22.5 Litres of Bardon bitter waiting for the yeasties to do their thing.

18 hours later at 20C and the yeast crop is beginning to form nicely

28 hours in and the yeast head looks like this.

7 days later and fermentation is finished

This is how it looks after a week, after another 3 days, it'll clear down considerably and be ready for kegging.

OK so it's been 8 days, gravity is 1.012, but now it's time to keg.

I will be using a plastic home brew keg for this how to.

The keg was cleaned with Oxyclean, then sanitised with a solution of cheap, thin, unscented bleach. Then rinsed well with cold tap water and finally swilled out with a kettle of boiling water. (Be careful)

50g of sugar (I used demerera, but use what you prefer) was weighed out.

The sugar was added to the keg.

Using a length of hose from the tap on the fermenter, the beer was run into the keg which mixed in the sugar.

Once all the beer was in the keg a burst of gas from an S30 cylinder was added.

After 5 minutes to allow the CO2 to settle, the lid was cracked to vent the air in the keg and leave a protective blanket of CO2.

This keg has a mechanical pressure relief valve, a further squirt of gas and the indicator can be seen to be OK (Green showing)

40 Pints of Bardon bitter conditioning.

I'll give it a couple of weeks before checking for clarity.

![BREWING THERMOMETER STICKERS ACCURATELY MONITOR FERMENTING BEER & WINE LIQUID TEMPERATURES 5PCS HOME BREW SPIRITS WINE LCD ADHESIVE [US]](https://m.media-amazon.com/images/I/311DDjo2X3L._SL500_.jpg)