peebee

Out of Control

I'd hinted at this arrangement in another thread, but might be better if I spawn a new thread to cover it:

The disadvantage I found with using regulators like this is many are apt to vent all pressure from the low pressure side when the high pressure side has no pressure. Needs a bit of working round.

I'd really like to hear from others who have dabbled with this type of arrangement.

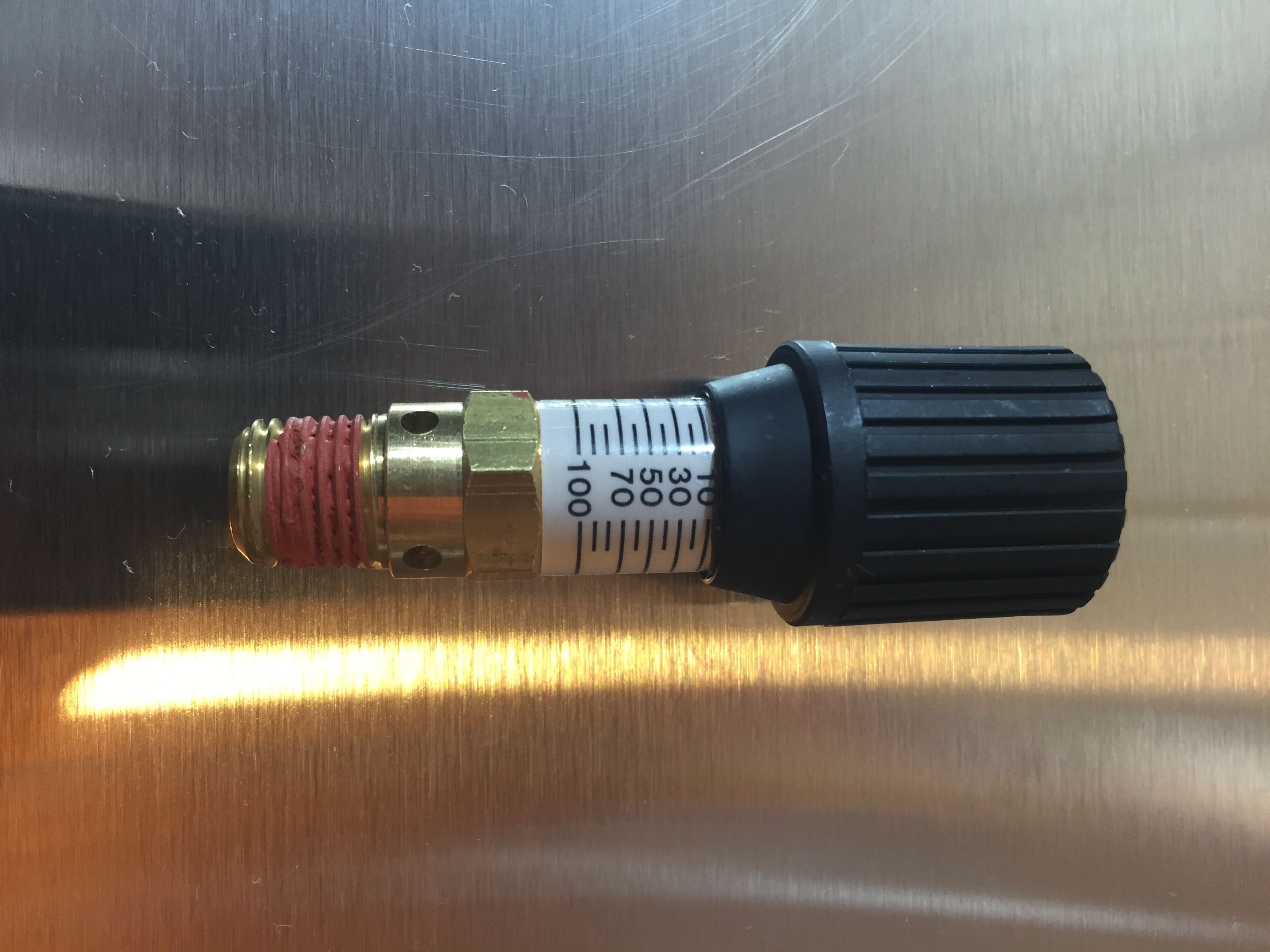

The AR2000 is a regulator. The AP100 I'm about to use is a pressure relief valve. But regulators can work as pressure relief valves and I wanted to use my favourite regulators at moment, the Shako NR200, but couldn't find what they relieved at or even if they did relieve. "Relieving" regulators can be a nightmare as my experiences with the Shako NUR regulator turned out (very precise PRV though), but the cruder relief mechanism used by many regulators looks just right (cruder, but still more sophisticated than the common "poppet" PRVs). "Relieving" regulators relieve pressure through the body, not the other port which for regulators is being used for high pressure in (10-16BAR max, these are "secondary" regulators I'm talking about, i.e. not connected directly to the CO2 bottle). The handy thing about using "relieving" regulators is they can have a gauge fitted directly to them instead of "tee-ed off" like the usual spunding valve design, and it is in place as a regulator when its done being a spunding valve. The NR200 (and AP100) are diaphragm type designs, much more precise than the common spring and plunger types.Long thread but worth reading.

https://aussiehomebrewer.com/threads/fermenting-under-pressure.66163/page-18#post-1492118

The disadvantage I found with using regulators like this is many are apt to vent all pressure from the low pressure side when the high pressure side has no pressure. Needs a bit of working round.

I'd really like to hear from others who have dabbled with this type of arrangement.