Cononthebarber

Landlord.

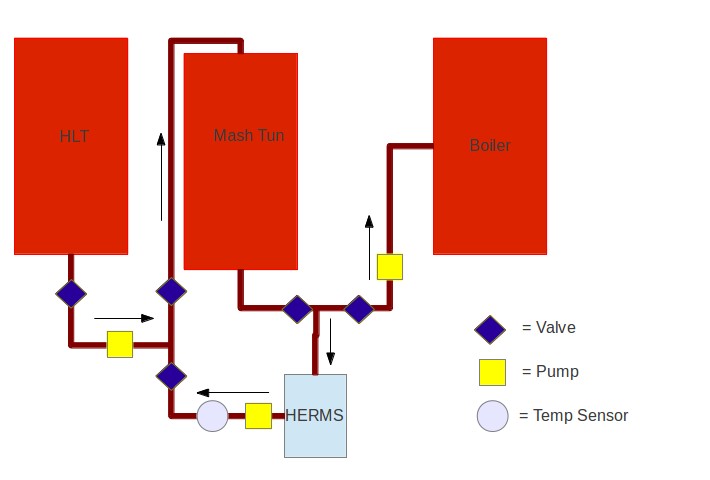

I have a plastic AG setup as per this link HERE...

As far as I can tell I will need a HLT which I assume I could just make another one of these?

Then I need a heat exchanger?

Reading around other posts I could but one of THESE and convert it with another kettle element and mini copper coil...

Then I need some pumps in order to move all the liquids around, do most people use THESE?

I've made a diagram for what I have in my head, does this make sense?

Thoughts and comments and suggestions will be greatly received...thanks in advance!

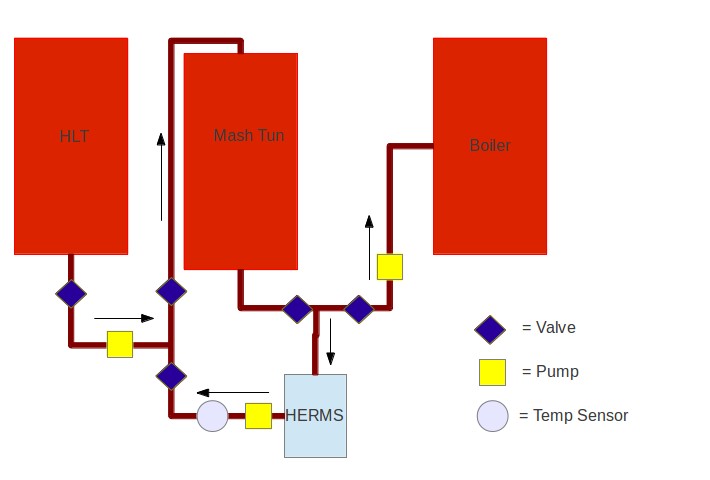

As far as I can tell I will need a HLT which I assume I could just make another one of these?

Then I need a heat exchanger?

Reading around other posts I could but one of THESE and convert it with another kettle element and mini copper coil...

Then I need some pumps in order to move all the liquids around, do most people use THESE?

I've made a diagram for what I have in my head, does this make sense?

Thoughts and comments and suggestions will be greatly received...thanks in advance!