Hi!

I found the amazing thread that Vossy published showing the Thermobox MT conversion with the false bottom - amazing. However, it scared the s**t out of me as I'm very inexperienced at using tools and practical projects!

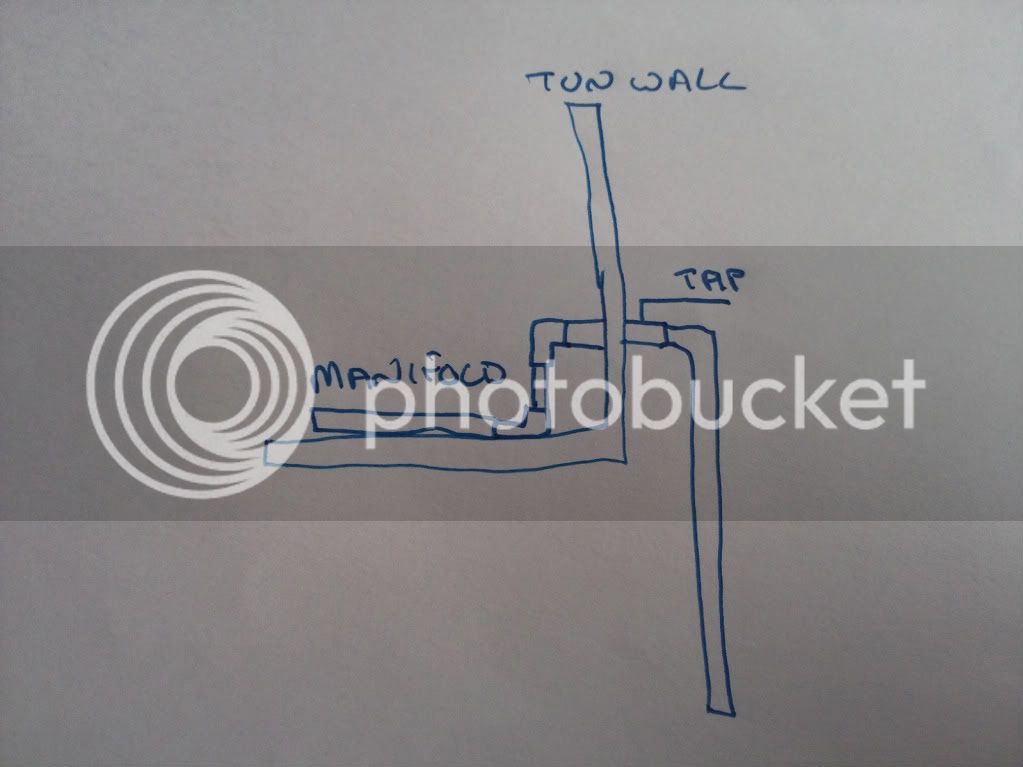

So - is it possible to still use a copper manifold attached to the back of a ball valve, just as you would in a coolbox? Or is that a bit of a waste in a Thermobox. I just don't think I can do the full-scale conversion

How much dead-space would there be just putting a ball-valve where the original tap was - would the manifold be close enough to the bottom to be effective?

I found the amazing thread that Vossy published showing the Thermobox MT conversion with the false bottom - amazing. However, it scared the s**t out of me as I'm very inexperienced at using tools and practical projects!

So - is it possible to still use a copper manifold attached to the back of a ball valve, just as you would in a coolbox? Or is that a bit of a waste in a Thermobox. I just don't think I can do the full-scale conversion

How much dead-space would there be just putting a ball-valve where the original tap was - would the manifold be close enough to the bottom to be effective?