here we go - pics of the process. This is basically a BIAB type approach with sparge steps. It was so easy a process, I actually brewed another batch on the same day to finish off some grain/styrians I had. So I ended up making a 10 L styrian stunner batch later on in the day!

The process using the oven went really well but the proof will be in the final product in 4-5 weeks time! :pray: Mash temp was maintained throughout in my little 11 L stockpot tun in the oven!

This smaller batch process highlighted an issue that I'd been having - BB suggested in another thread that maybe my astringency smell/taste was due to oversparging - basically this has proved I've been doing just that as the 3rd batch sparge step was too much and there was a really strong astringent smell. When I checked the gravity, the brix reading was 2.5 which is too low! Root cause: My software settings were set to 80% mash efficiency for some reason which is too high whereas I originally started out last year with a 70% setting! maybe I'd been playing somewhere! The efficiency setting was wound back to 70% for the 2nd batch and this was much better... Duh! :hmm:

Pics:

empty 21L boiler stock pot with fashioned #40 mesh filter!

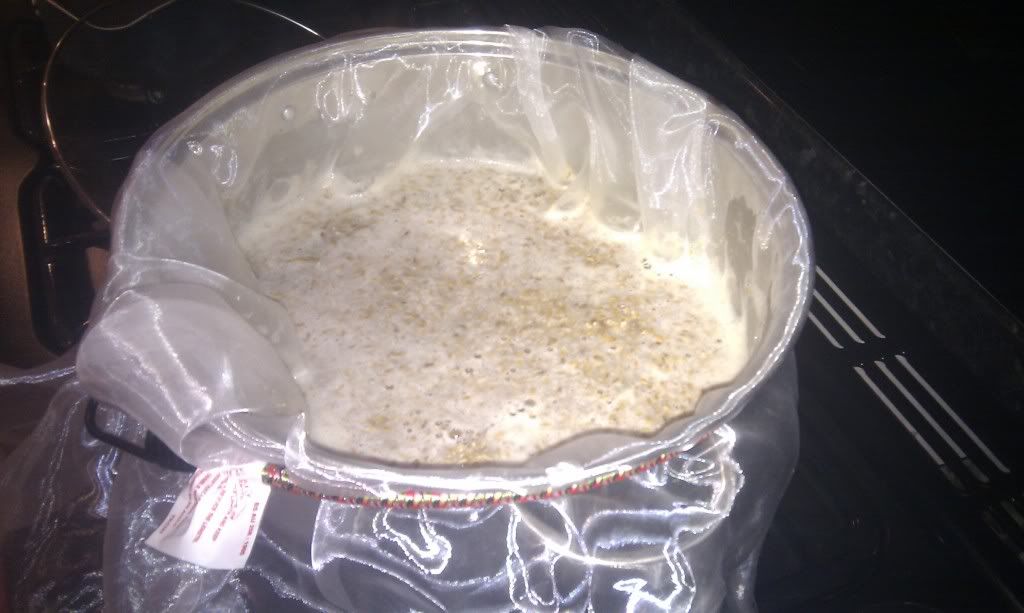

Grain bill

Mash in oven! on a low setting the oven maintained a constant 67C mash temp.

Mash on..

Heating up the sparge water on the wok burner

Batch Sparge 1

Result from 1st batch sparge

Pulling the voile bag after sparging..

coming up to the boil

first hops weighed

first hops in

Cooler in - cooled in 10 mins!

Running off into FV

Runoff Volume.

Post boil gunk.

![BREWING THERMOMETER STICKERS ACCURATELY MONITOR FERMENTING BEER & WINE LIQUID TEMPERATURES 5PCS HOME BREW SPIRITS WINE LCD ADHESIVE [US]](https://m.media-amazon.com/images/I/311DDjo2X3L._SL500_.jpg)