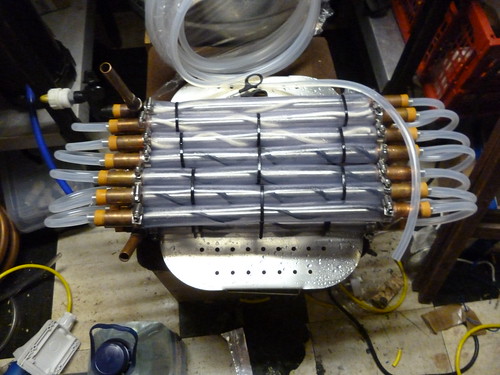

We had a MCB workshop on Saturday where we made among other things a counterflow chiller.( My thanks to Chris for his excellent workshop at the Spring Thing and from where I got the idea) I could not believe how efficient it was because when we tested it out,the boiling water came down to 16c at the outlet.

When I got home I decided to modify it so it would fit into an old SS Burco boiler (mini) so the whole thing could be kept clean and tidy in a sealed container.

I will post some pictures shortly but my question for the moment is what steps should I take to keep it fully sanitised both in use and in storage?

When I got home I decided to modify it so it would fit into an old SS Burco boiler (mini) so the whole thing could be kept clean and tidy in a sealed container.

I will post some pictures shortly but my question for the moment is what steps should I take to keep it fully sanitised both in use and in storage?