Hi everyone,

my name is Paul. I was born and bred in Sunderland UK.

Most recently my son asked if we could start a bit of a nano-brewing company off. (Yeah right). His idea being his Chemical Engineering degree, and my automotive paint system circulation knowledge would give us a slight advantage on most people just starting out.

We ordered a stainless steel HLT, Mash tun, and BK. I have also added an electric pump, double wort chiller and 2 chest freezers (second hand for £30 that are controlled externally by a thermo controller).

After realising I may have gone a bit overboard, and knowing I have very little knowledge with brewing, off I went searching the internet and reading post after post. However, I didn't want to delve into full grain brewing before starting with the infant stages, so I convinced my son to take one step at a time, and out I went and bought some second hand equipment.

Plastic 60lt twin element boiler, 60lt Plastic Fermenter with tap, Cooler box converted to a mash tun, with sparging and filtration added, 2 x 23lt plastic kegs with s3o co2 fittings on caps, hydrometer, bottle filler, syphoning tubes, thermometer, jugs, funnels, yeast bottle, all for £25 (Absolute bargain).

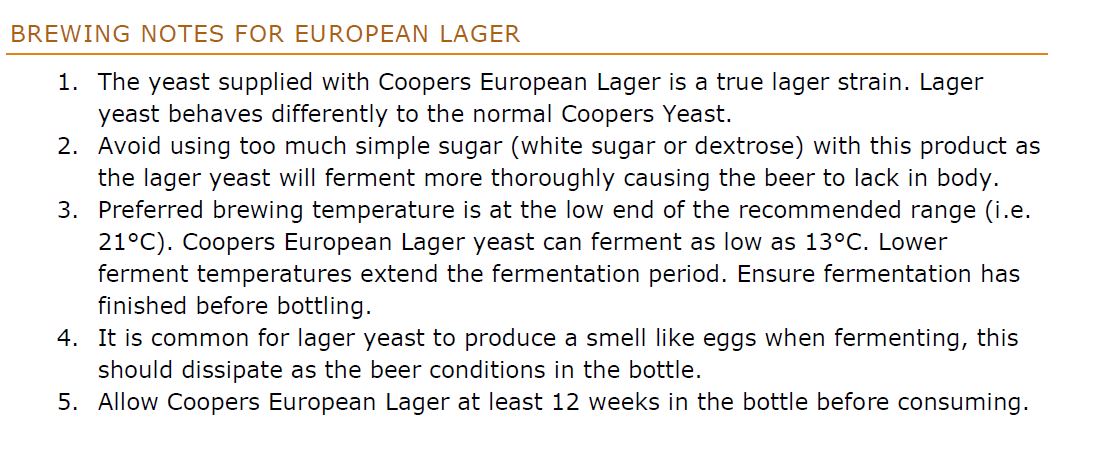

Decided to start with Coopers European Lager (Extract)

Sanitation and Brew day was Friday 13th July (what a date to start on lol...)

Followed all instructions on packet and put fermenter into one of the controlled freezers at 13 degrees C (recommended on a forum I was reading)

Noticed we had missed one basic step in our excitement, which was the OG, but I though that as we gad followed all other instructions to the letter, then we would be somewhere near at the end FG

Problem. After 5 days I noticed we didn't get any foam, or crude on the top of the fermentation, so I re-stirred to see if it would start the fermentation.

Left it all until today as I have been on holiday. Still no foam on top. Took a sample and checked SG with hydrometer and it is reading 1013. Even if the OG was 1040 this would give an ABV of 3.2%. Not very good.

Has something gone wrong, or should I just leave it and give it more time.

my name is Paul. I was born and bred in Sunderland UK.

Most recently my son asked if we could start a bit of a nano-brewing company off. (Yeah right). His idea being his Chemical Engineering degree, and my automotive paint system circulation knowledge would give us a slight advantage on most people just starting out.

We ordered a stainless steel HLT, Mash tun, and BK. I have also added an electric pump, double wort chiller and 2 chest freezers (second hand for £30 that are controlled externally by a thermo controller).

After realising I may have gone a bit overboard, and knowing I have very little knowledge with brewing, off I went searching the internet and reading post after post. However, I didn't want to delve into full grain brewing before starting with the infant stages, so I convinced my son to take one step at a time, and out I went and bought some second hand equipment.

Plastic 60lt twin element boiler, 60lt Plastic Fermenter with tap, Cooler box converted to a mash tun, with sparging and filtration added, 2 x 23lt plastic kegs with s3o co2 fittings on caps, hydrometer, bottle filler, syphoning tubes, thermometer, jugs, funnels, yeast bottle, all for £25 (Absolute bargain).

Decided to start with Coopers European Lager (Extract)

Sanitation and Brew day was Friday 13th July (what a date to start on lol...)

Followed all instructions on packet and put fermenter into one of the controlled freezers at 13 degrees C (recommended on a forum I was reading)

Noticed we had missed one basic step in our excitement, which was the OG, but I though that as we gad followed all other instructions to the letter, then we would be somewhere near at the end FG

Problem. After 5 days I noticed we didn't get any foam, or crude on the top of the fermentation, so I re-stirred to see if it would start the fermentation.

Left it all until today as I have been on holiday. Still no foam on top. Took a sample and checked SG with hydrometer and it is reading 1013. Even if the OG was 1040 this would give an ABV of 3.2%. Not very good.

Has something gone wrong, or should I just leave it and give it more time.