MR2Jay77

Junior Member

Morning Peeps :thumb:

Been doing loads of research and I think I've got my head around my first experimental 1 Gallon beer batch. I would like you guys to look over it though with all your experience.

I'm going for small batches as I don't have the room I used to. Plus, with this method I'll only end up with 9 bottles of muck rather than 40 if it all goes Pete Tong :lol:

So here is my first attempt. Any pointers on how I could tweak it or is it worth bashing on and seeing what comes out the end?

Ingredients

1. 60g Crystal Malt (30 min Steep)

2. 500g DME (Light Spraymalt)

3. 10g Cascade Hops (15 min boil)

4. 4g Cascade Hops (5 min boil)

5. 4g Cascade Hops (20 min steep)

6. 4g Cascade Hops (Dry Hop)

7. Muntons Premium Gold Ale Yeast

8. 36g Brewing sugar (for priming)

Method

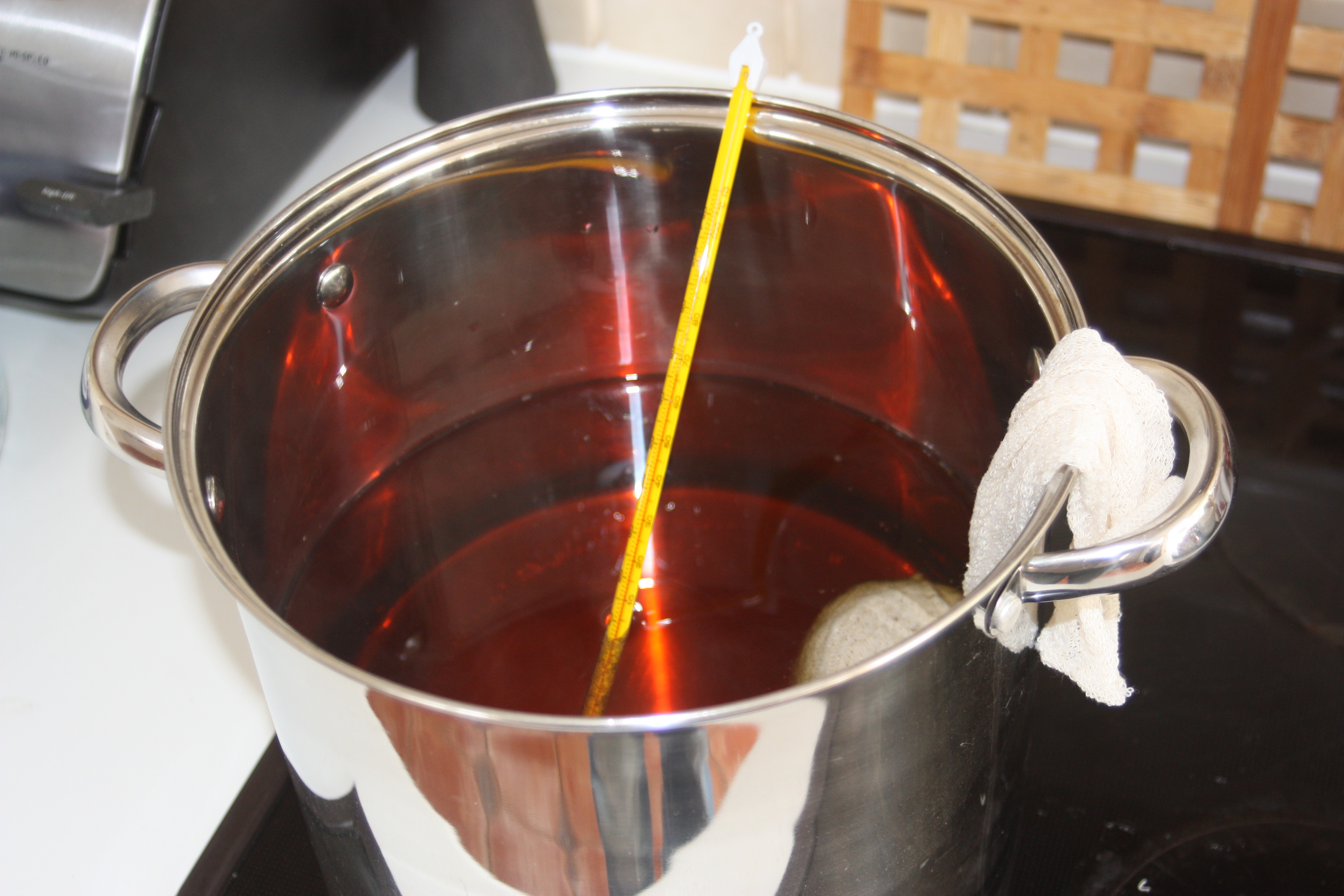

1. Bring 4l bottled water up to 66 degrees C and steep the Crystal malt in a muslin bag for 30 minutes

2. Add the DME and stir until dissolved

3. Bring to the boil (Donââ¬â¢t let it boil over) and add the first 10g of hops

4. After 10 minutes, add another 4g of hops and boil for a further 5 mins

5. Turn off the heat and reduce the temp to 80 degrees C. Add a further 4g of hops

6. Allow to steep for a further 20 mins

7. Top up the wort to 5 litres with bottled water and stir through

8. Place pan in cold water and bring the temperature of the wort down to 22 degrees C

9. Transfer the wort to a Fermenting Bucket through a sieve to strain out the solids

10. Pitch the yeast and allow to ferment

11. When fermentation has died down to about 2 bubbles per minute, transfer off the lees to a demijohn, top up to the neck and dry hop with the last 4g of hops

12. Leave for 2 weeks to allow the secondary fermentation to complete.

13. Prepare the priming solution of 36g brewing sugar in 250ml boiling water in the fermenting bucket

14. Decant the beer from the lees into the fermenting bucket with the sugar solution.

15. Lightly stir the sugar solution into the beer taking care not to agitate too much

16. Bottle the beer and leave to prime for about 2 weeks

17. Chill and enjoy

Been doing loads of research and I think I've got my head around my first experimental 1 Gallon beer batch. I would like you guys to look over it though with all your experience.

I'm going for small batches as I don't have the room I used to. Plus, with this method I'll only end up with 9 bottles of muck rather than 40 if it all goes Pete Tong :lol:

So here is my first attempt. Any pointers on how I could tweak it or is it worth bashing on and seeing what comes out the end?

Ingredients

1. 60g Crystal Malt (30 min Steep)

2. 500g DME (Light Spraymalt)

3. 10g Cascade Hops (15 min boil)

4. 4g Cascade Hops (5 min boil)

5. 4g Cascade Hops (20 min steep)

6. 4g Cascade Hops (Dry Hop)

7. Muntons Premium Gold Ale Yeast

8. 36g Brewing sugar (for priming)

Method

1. Bring 4l bottled water up to 66 degrees C and steep the Crystal malt in a muslin bag for 30 minutes

2. Add the DME and stir until dissolved

3. Bring to the boil (Donââ¬â¢t let it boil over) and add the first 10g of hops

4. After 10 minutes, add another 4g of hops and boil for a further 5 mins

5. Turn off the heat and reduce the temp to 80 degrees C. Add a further 4g of hops

6. Allow to steep for a further 20 mins

7. Top up the wort to 5 litres with bottled water and stir through

8. Place pan in cold water and bring the temperature of the wort down to 22 degrees C

9. Transfer the wort to a Fermenting Bucket through a sieve to strain out the solids

10. Pitch the yeast and allow to ferment

11. When fermentation has died down to about 2 bubbles per minute, transfer off the lees to a demijohn, top up to the neck and dry hop with the last 4g of hops

12. Leave for 2 weeks to allow the secondary fermentation to complete.

13. Prepare the priming solution of 36g brewing sugar in 250ml boiling water in the fermenting bucket

14. Decant the beer from the lees into the fermenting bucket with the sugar solution.

15. Lightly stir the sugar solution into the beer taking care not to agitate too much

16. Bottle the beer and leave to prime for about 2 weeks

17. Chill and enjoy

![BREWING THERMOMETER STICKERS ACCURATELY MONITOR FERMENTING BEER & WINE LIQUID TEMPERATURES 5PCS HOME BREW SPIRITS WINE LCD ADHESIVE [US]](https://m.media-amazon.com/images/I/311DDjo2X3L._SL500_.jpg)