Hi all.

I'm finally getting round to planning and building my first ever AG setup and would like some advice in the planning stages so I don't pork it up.

So far I have:

Stand: Made from Unistrut, 2m long, 67cm wide and high. I am hoping to get some old kitchen worktop for the top and bottom (this will help with rigidity of the stand too), with the top having 2 x 60cm diameter holes cut in for my 2 stainless vessels.

Brewing Vessels: I have 2 x 20Gal stainless steel ex-dairy vessels (purchased from fleabay for £50 :party: ). Each is 60cm in diameter with a top lip and supports that I plan to sit on the top worktop surface. Each vessel has slightly sloping sides and a domed bottom with a bottom drain hole which can be plugged by a demi john bung.

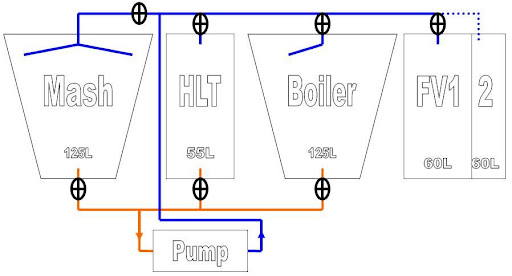

Miscelleaneous: I also have a homemade 55L HDPE plastic 2-element boiler.

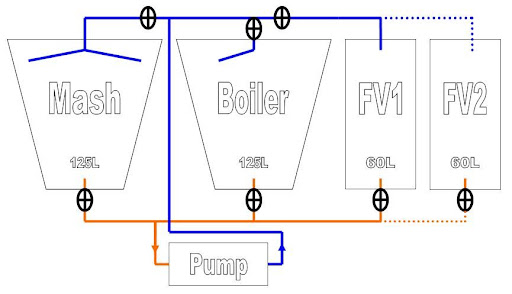

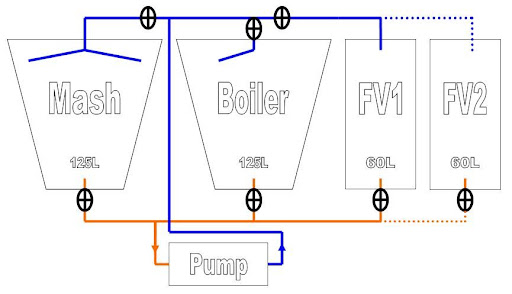

My initial plan was to use one SS vessel as the HLT and boiler (2,3 or 4 kettle elements?), and the other as the mash tun. I would transfer strike temp water from boiler to mash tun, refill boiler and heat to sparge temp, pump sweet wort to fv, batch sparge from boiler x 2 with sweet wort going to fv and then back to boiler for the boil. All sounds a little complicated, but looks like this:

Am i right in thinking that a normal brew may look like this approximately:

Mash = 25kg grain & (2.5*25) 62.5l liqour

Drain to FV = 35L (after loss to grain)

Sparge 1 = 35L (in and out)

Sparge 2 = 35L (in and out)

Sweet wort = 105L

Bitter wort (correct term?) = 85L (After loss to evaporation and hops)

If I am speaking out of my a**e then please let me know so that I don't ruin some perfectly good equipment. Sorry for bombarding with all this stuff - I hope you don't end up as confused as me :)

PS I've just though that I could use the SS boiler for the strike water and the plastic boiler for the batch sparging - would make things simpler... :hmm:

I'm finally getting round to planning and building my first ever AG setup and would like some advice in the planning stages so I don't pork it up.

So far I have:

Stand: Made from Unistrut, 2m long, 67cm wide and high. I am hoping to get some old kitchen worktop for the top and bottom (this will help with rigidity of the stand too), with the top having 2 x 60cm diameter holes cut in for my 2 stainless vessels.

Brewing Vessels: I have 2 x 20Gal stainless steel ex-dairy vessels (purchased from fleabay for £50 :party: ). Each is 60cm in diameter with a top lip and supports that I plan to sit on the top worktop surface. Each vessel has slightly sloping sides and a domed bottom with a bottom drain hole which can be plugged by a demi john bung.

Miscelleaneous: I also have a homemade 55L HDPE plastic 2-element boiler.

My initial plan was to use one SS vessel as the HLT and boiler (2,3 or 4 kettle elements?), and the other as the mash tun. I would transfer strike temp water from boiler to mash tun, refill boiler and heat to sparge temp, pump sweet wort to fv, batch sparge from boiler x 2 with sweet wort going to fv and then back to boiler for the boil. All sounds a little complicated, but looks like this:

Am i right in thinking that a normal brew may look like this approximately:

Mash = 25kg grain & (2.5*25) 62.5l liqour

Drain to FV = 35L (after loss to grain)

Sparge 1 = 35L (in and out)

Sparge 2 = 35L (in and out)

Sweet wort = 105L

Bitter wort (correct term?) = 85L (After loss to evaporation and hops)

If I am speaking out of my a**e then please let me know so that I don't ruin some perfectly good equipment. Sorry for bombarding with all this stuff - I hope you don't end up as confused as me :)

PS I've just though that I could use the SS boiler for the strike water and the plastic boiler for the batch sparging - would make things simpler... :hmm:

):

):