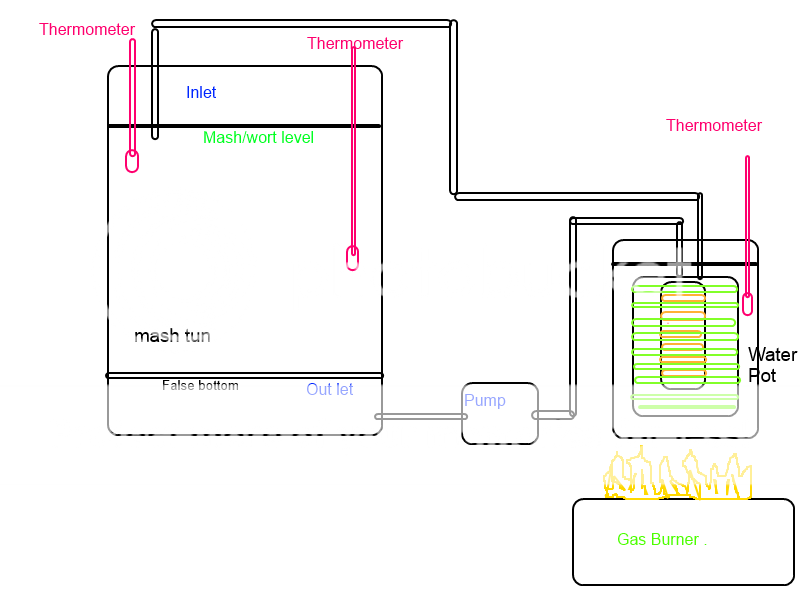

Just won myself a nice 10L SS Baby Burco on ebay for £6.50 and intend using it to make my first HERMS system. I have 4 metres of 10mm copper coil left over from an immersion cooler I made. My plan is to coil this around a CO2 gas cylinder and fit the coil to the lid of the Burco with 1/2" BSP hex nipples, so that I can take off the tubing for flow and return from the mash tun. I understand the HERMS process ok, but I've struggled to find an idiot's guide to actually building one from scratch that includes, for instance, how to fit a pump inline. I have a nice 12v mag drive pump which I intend to use. I might also add that I have a a very nice Auberins PID unit that I built myself. Anyone got a simple diagram of pipe connections and what goes where in a HERMS?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help in building a HERMS system

- Thread starter chastuck

- Start date

Help Support The Homebrew Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Oct 17, 2011

- Messages

- 4,116

- Reaction score

- 984

when i set up my test rig it went

tun -> underback ->/or pump -> coil -> restriction valve -> sensor and return to tun.

i was using a pump ok to restrict otherwise fit a diverting flow control assembly before the coil to control the flow speed. or if using speed control on a solar pump ignore completely

lagging pipework post h/e is a good idea to retain the heat.

its the temp at return to the tun u want to measure as if thats at target it will move the bulk towards target.

tun -> underback ->/or pump -> coil -> restriction valve -> sensor and return to tun.

i was using a pump ok to restrict otherwise fit a diverting flow control assembly before the coil to control the flow speed. or if using speed control on a solar pump ignore completely

lagging pipework post h/e is a good idea to retain the heat.

its the temp at return to the tun u want to measure as if thats at target it will move the bulk towards target.

pittsy

Landlord.

Vossy1

Landlord.

Mines pretty much like pittsy's but using an electric element in the HE. I have a flow restricting valve on the pump outlet plumbing to control the flow rate of the recirc, and my PT100 is in the outlet of the HE, I do double check the mash temp with a 'roving' probe.

Thanks to all for help. I'm much clearer about how to proceed now. A quick question about the heat exchanger - do you flow in at the bottom and out at the top, or is it vice versa? As soon as I make a start on construction I'll post up my efforts.

pittsy

Landlord.

If i understand you then it's basically a wort chiller so pipe in and out at the top so no/less leaks (mine is through the lid.

£8.99 (£158.55 / kg)

Fermaid O Yeast Nutrient - 2 oz (56.7 g) - Make Wine Cider Mead Kombucha at Home - Sold by CAPYBARA Distributors Inc.

CAPYBARA Distributors Inc. (UK)

£9.99 (£199.80 / kg)

Lalvin EC-1118 Wine Yeast (10 Pack) - Champagne Yeast - Make Wine Cider Mead Kombucha At Home - 5 g Sachets - Saccharomyces cerevisiae - Sold by CAPYBARA Distributors Inc.

CAPYBARA Distributors Inc. (UK)

£63.25

Sanitary clamp 1.5" (38mm) OD50.5mm Sanitary Tri-Clamp 90-Degree Pipe With Nipple And Electronic Thermometer, Stainless Steel 304 Home brewing(Without Thermometer)

DAN CHENG XIAN PENG SHI DA SHANG MAO DIAN

£14.25

£18.99

How to Brew: Everything You Need to Know to Brew Great Beer Every Time

Amazon.co.uk

£11.48

Banziaju Wine Making Supplies, 18" Auto Siphon Hose For Water Homebrew Siphon Pump With Tubing And Clamp Clear Wine Siphon For Beer Wine Making Kit

Jian Shi Xian Chao Mei Shang Mao You Xian Gong Si

£11.95

£14.99

WATER COMPREHENSIVE GUIDE (Brewing Elements): A Comprehensive Guide for Brewers

Amazon.co.uk

£17.95

£24.95

DIAH DO IT AT HOME Fermenter 30l Fermentation Bucket with Tap, Airlock, Lid, and Bung, Homebrew Wine Making

do-it-at-home

£38.63 (£0.39 / 100 ml)

Cider Making Kit - Full Starter - 10L/2 Gallon/20 Pints Home brew Beer Ale Lager

247 Homebrew

£11.81

Digital Temperature Watch Heating Thermometer Home Brewing Tools for Wine Bottle

B&D DIRECT STORE

£11.95

£14.99

Brew it Yourself: Make Your Own Beer, Wine, Cider and Other Concoctions

ST Bookstores

£15.96

£16.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.co.uk

£7.00 (£70.00 / kg)

£7.25 (£72.50 / kg)

Youngs Multi Purpose Dried Active Yeast

TMJ.DISTRIBUTIONS

£6.99

Stevenson Reeves Triple Scale Hydrometer (S1011) For Home Brewing and Winemaking

Medi Exchange

£7.99

£14.99

Craft Brew: 50 homebrew recipes from the world's best craft breweries

Sarahs Bookshop UK

£11.95

£14.99

FOR THE LOVE OF HOPS (Brewing Elements): The Practical Guide to Aroma, Bitterness and the Culture of Hops

Amazon.co.uk

Vossy1

Landlord.

Design really depends on materials used and what you want. The reason my HE enters at the top and exits the bottom is because originally I used copper pipe. Copper if let to stand with water and air exposed to it will form verdigris, which you definitely don't want as it's poisonous with continued or high level exposure (picture green pigment on copper roofs). So unless you have the ability to thoroughly dry a copper coil, or keep it flooded with water in between uses, I would think about design and using a top and bottom entry copper HE. If you use stainless for your HE this isn't a problem, though again the coil could really do with being dried or flooded between uses to prevent nasties growing in the tubing.

My system used to be all copper pipe, the reason for replacing it with stainless is above, it's is personal choice as i see myself in this hobby for the long run and want to minimise any 'risk', loads of folks use copper without issues.

My system used to be all copper pipe, the reason for replacing it with stainless is above, it's is personal choice as i see myself in this hobby for the long run and want to minimise any 'risk', loads of folks use copper without issues.

A very good point, and one I didn't consider. I guess even if you leave the pipe flooded verdigris could grow as there's oxygen in the water. I have a 10bar 24L air compressor which I could use to blow out water after rinsing. I was also going to use push-fit pipe fittings on the coil uprights, so I might be able to dismantle the coil from the lid and put it in the oven. Thanks for the tip.Vossy1 said:Design really depends on materials used and what you want. The reason my HE enters at the top and exits the bottom is because originally I used copper pipe. Copper if let to stand with water and air exposed to it will form verdigris, which you definitely don't want as it's poisonous with continued or high level exposure (picture green pigment on copper roofs). So unless you have the ability to thoroughly dry a copper coil, or keep it flooded with water in between uses, I would think about design and using a top and bottom entry copper HE. If you use stainless for your HE this isn't a problem, though again the coil could really do with being dried or flooded between uses to prevent nasties growing in the tubing.

My system used to be all copper pipe, the reason for replacing it with stainless is above, it's is personal choice as i see myself in this hobby for the long run and want to minimise any 'risk', loads of folks use copper without issues.

Hello I built myself a HERMS system and what I did was to have the hot liquor from the HLT pass through the herms to first fill the Mash Tun. Then I would recirculate the liquor at the desired temp via the HERMS. The temp of the wort is measured at the wort exiting the HERMS. Then when I have completed the mashing I transfer the wort via another pump and push the sparge liquor through the HERMS to flush the remaining wort.

evanvine

Landlord.

+1loads of folks use copper without issues.

again +1push the sparge liquor through the HERMS to flush the remaining wort.

tazuk

Landlord.

here is my herms set up :thumb:

[/URL]

[/URL]

[/URL]

[/URL]

evanvine

Landlord.

That is an excellent way of doing it, several others also agree!

metal micky

Active Member

Hi

I would appreciate any advice.

Looking at the diagrams of the HERMS setup the preferred method is the pump prior to the coil, is there a reason for this?

I was looking at gravity from the mash tun to the coil and the pump on the return to mash tun side.

I would appreciate any advice.

Looking at the diagrams of the HERMS setup the preferred method is the pump prior to the coil, is there a reason for this?

I was looking at gravity from the mash tun to the coil and the pump on the return to mash tun side.

pittsy

Landlord.

Hi usually you have the pump at the start because you will need to feed some liquid into it before it works so closer to the liquid the easier to use otherwise it'll be empty and won't suck/pump .

metal micky

Active Member

Thanks pittsey

possible priming issue then if using a solar pump,

Flow is from the dead space of the mash tun to top of the coil, out from bottom of the coil

via a ball valve at the bottom of the vessel, flexible s/s hose to the pump, then up to top of the mash tun.

if I fill the pump with water first and start circulating before adding the grain to the mash tun could this work.

I assumed that the pump would be needed on the return side due to the work it will do to push the liquid

the 2-3ft back into the mash tun, also if any grains etc get through the filter this would settle in the pipe from

the mash tun to the top of the coil.

possible priming issue then if using a solar pump,

Flow is from the dead space of the mash tun to top of the coil, out from bottom of the coil

via a ball valve at the bottom of the vessel, flexible s/s hose to the pump, then up to top of the mash tun.

if I fill the pump with water first and start circulating before adding the grain to the mash tun could this work.

I assumed that the pump would be needed on the return side due to the work it will do to push the liquid

the 2-3ft back into the mash tun, also if any grains etc get through the filter this would settle in the pipe from

the mash tun to the top of the coil.

Similar threads

- Replies

- 31

- Views

- 4K

- Locked

Equipment For Sale

3.5 vessel electric HERMS set up

- Replies

- 6

- Views

- 1K

- Replies

- 4

- Views

- 1K

- Replies

- 14

- Views

- 5K

![BREWING THERMOMETER STICKERS ACCURATELY MONITOR FERMENTING BEER & WINE LIQUID TEMPERATURES 5PCS HOME BREW SPIRITS WINE LCD ADHESIVE [US]](https://m.media-amazon.com/images/I/311DDjo2X3L._SL500_.jpg)