tommillski

Active Member

- Joined

- Jan 24, 2013

- Messages

- 24

- Reaction score

- 0

After having good success brewing kits I decided it was time to step up and have more control over the brewing process. The next obvious step from kits is extract brewing, however I also wanted the ability to move on to BIAB without too much hassle. With this in mind I added a 50l boiler to my ever increasing collection of equipment. Special mentions to both Rob at the Malt Miller and Vossy for their impeccable service, cheers guys! :hat:

My christening brew in my new kettle is a London Pride Clone - it's a fairly simple but very tasty beer which I hoped would ease me into the extra steps involved in extract brewing.

Ingredients:

13g Target Hops

7g Challenger

7g Northdown

19g East Kent Goldings

370 g Crystal Malt

2.5kg Light dried malt extract

WYeast Activator 1968 - London ESB Ale

After thoroughly cleaning and sanitising all of the equipment I set about heating the water to 65°c.

Whilst the water was getting up to temperature I had time to measure my ingredients and make sure I had everything ready for the brew, including activating the yeast.

The crushed grains are then steeped in the heated water. This will add colour, body and flavour to the finished beer.

After 30 minutes the grains are removed, and 1kg of DME (Dried Malt Extract) is added. I sat the grains in a strainer above the wort so that i could catch every drop of goodness. I gradually poured the DME in whilst stirring the wort so that it didn't clump up and was properly dissolved.

Next I turned the hob up and waited for the wort to boil. This takes a while using a domestic hob, so its the perfect time to crack a home brew!

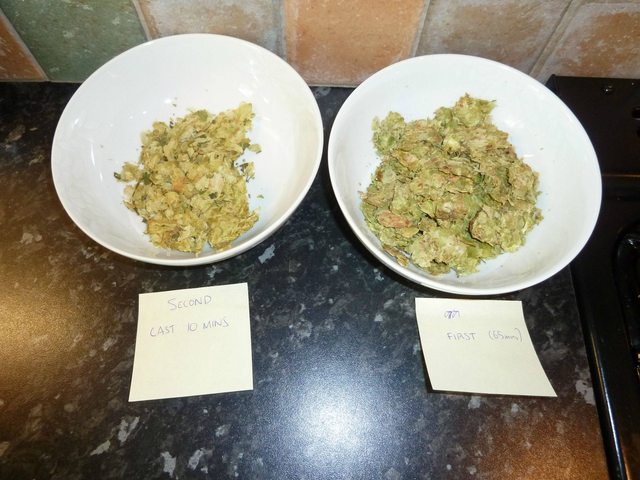

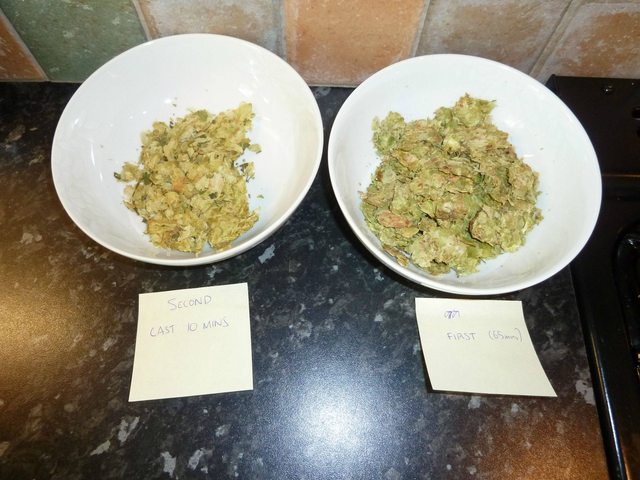

Once there was a strong rolling boil I added the first round of hops, the bittering hops. As soon as they hit the wort the smell is incredible.

After 65 minutes the aroma hops are added. In this case i'm using Challenger hops.

After a further 10 minutes the gas is turned off and the rest of the malt extract added.

Next up was cooling the wort to between 18-24°c - a safe temperature to pitch the yeast. I didn't take a picture of this stage, but I think it is where i learnt the most. As i don't have an immersion or counterflow chiller, or even a no-chill cube, so my only other option was to chill the pot in a bath of cold water. Carrying the boiling wort up the stairs wasn't exactly practical, and the time that it took to get the wort down to a suitable pitching temperature - about 40 minutes - isn't going to be quick enough to produce a good cold-break when using the BIAB method; so from this experience I think an immersion chiller is going to be a wise purchase.

Once the wort is at the correct temperature it is time to transfer it from the kettle to a fermenting vessel whist trying to aerate the wort as much as possible

By now the yeast has started working and the pack has expanded, so it's ready to pitch.

I hit my O.G pretty much dead on (Target:1.041)

And that's it! It's now tucked away for a few days before dry hopping and eventually cold crashing before bottling. Cheers! :

My christening brew in my new kettle is a London Pride Clone - it's a fairly simple but very tasty beer which I hoped would ease me into the extra steps involved in extract brewing.

Ingredients:

13g Target Hops

7g Challenger

7g Northdown

19g East Kent Goldings

370 g Crystal Malt

2.5kg Light dried malt extract

WYeast Activator 1968 - London ESB Ale

After thoroughly cleaning and sanitising all of the equipment I set about heating the water to 65°c.

Whilst the water was getting up to temperature I had time to measure my ingredients and make sure I had everything ready for the brew, including activating the yeast.

The crushed grains are then steeped in the heated water. This will add colour, body and flavour to the finished beer.

After 30 minutes the grains are removed, and 1kg of DME (Dried Malt Extract) is added. I sat the grains in a strainer above the wort so that i could catch every drop of goodness. I gradually poured the DME in whilst stirring the wort so that it didn't clump up and was properly dissolved.

Next I turned the hob up and waited for the wort to boil. This takes a while using a domestic hob, so its the perfect time to crack a home brew!

Once there was a strong rolling boil I added the first round of hops, the bittering hops. As soon as they hit the wort the smell is incredible.

After 65 minutes the aroma hops are added. In this case i'm using Challenger hops.

After a further 10 minutes the gas is turned off and the rest of the malt extract added.

Next up was cooling the wort to between 18-24°c - a safe temperature to pitch the yeast. I didn't take a picture of this stage, but I think it is where i learnt the most. As i don't have an immersion or counterflow chiller, or even a no-chill cube, so my only other option was to chill the pot in a bath of cold water. Carrying the boiling wort up the stairs wasn't exactly practical, and the time that it took to get the wort down to a suitable pitching temperature - about 40 minutes - isn't going to be quick enough to produce a good cold-break when using the BIAB method; so from this experience I think an immersion chiller is going to be a wise purchase.

Once the wort is at the correct temperature it is time to transfer it from the kettle to a fermenting vessel whist trying to aerate the wort as much as possible

By now the yeast has started working and the pack has expanded, so it's ready to pitch.

I hit my O.G pretty much dead on (Target:1.041)

And that's it! It's now tucked away for a few days before dry hopping and eventually cold crashing before bottling. Cheers! :

![BREWING THERMOMETER STICKERS ACCURATELY MONITOR FERMENTING BEER & WINE LIQUID TEMPERATURES 5PCS HOME BREW SPIRITS WINE LCD ADHESIVE [US]](https://m.media-amazon.com/images/I/311DDjo2X3L._SL500_.jpg)