Bigjas

Landlord.

I thought I would have a go at making my own temperature control for my brew fridge. I also like documenting my builds and experiences, so here it is. First off, this is not a tutorial, I am not an electrician or have any electrical experience, just getting my excuses in earlyââ¬Â¦Ã¢â¬Â¦.. I also felt it might be of some use to anyone who is thinking of setting up a brew fridge.I bought my tall larder fridge second hand from Gumtree for �ã20. It was a bit manky but it works ok, so plenty of bleach was used to get it clean. I keep it in my garage which gets cold in the winter so it will be interesting to see how well it works over the next few months.

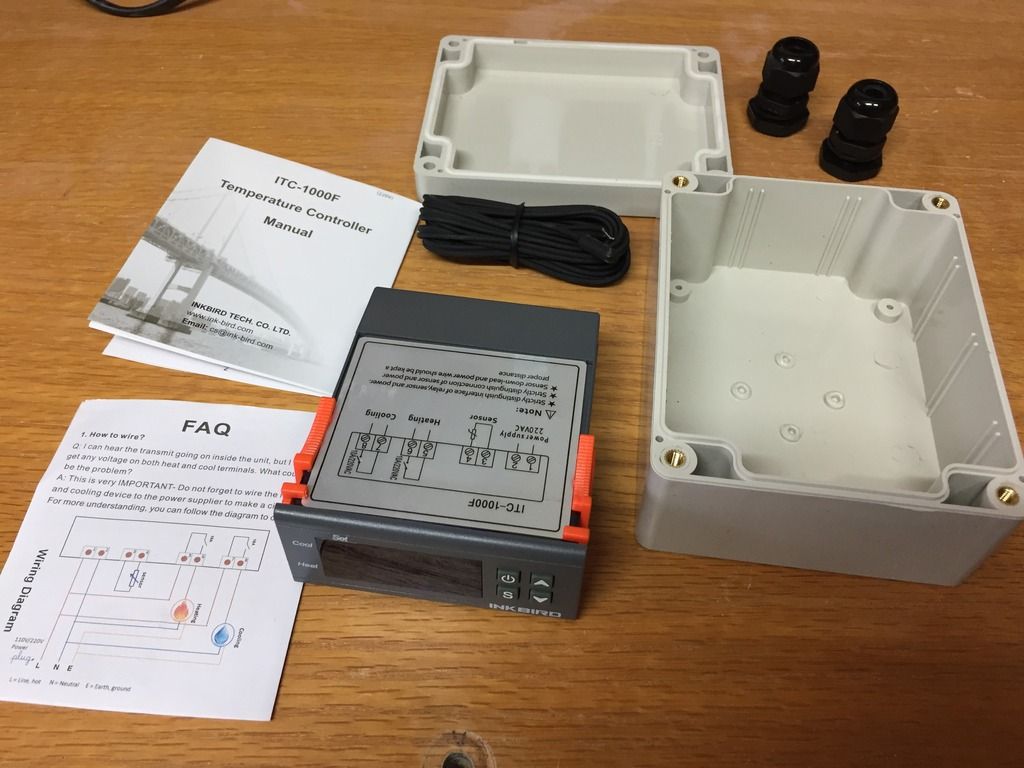

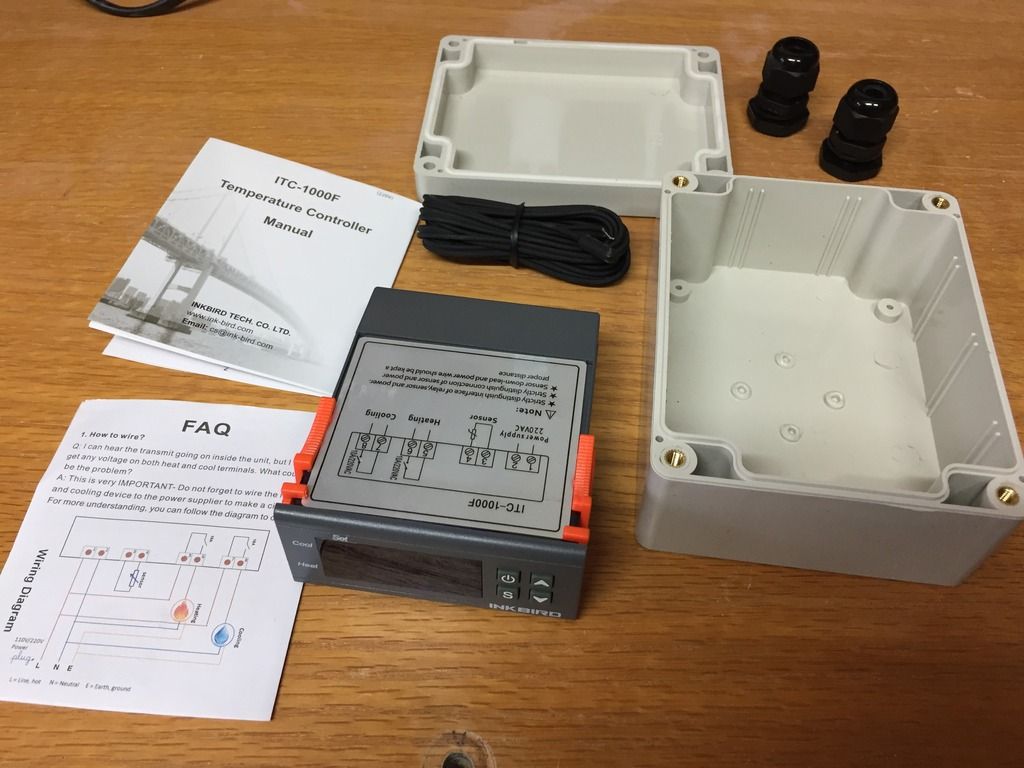

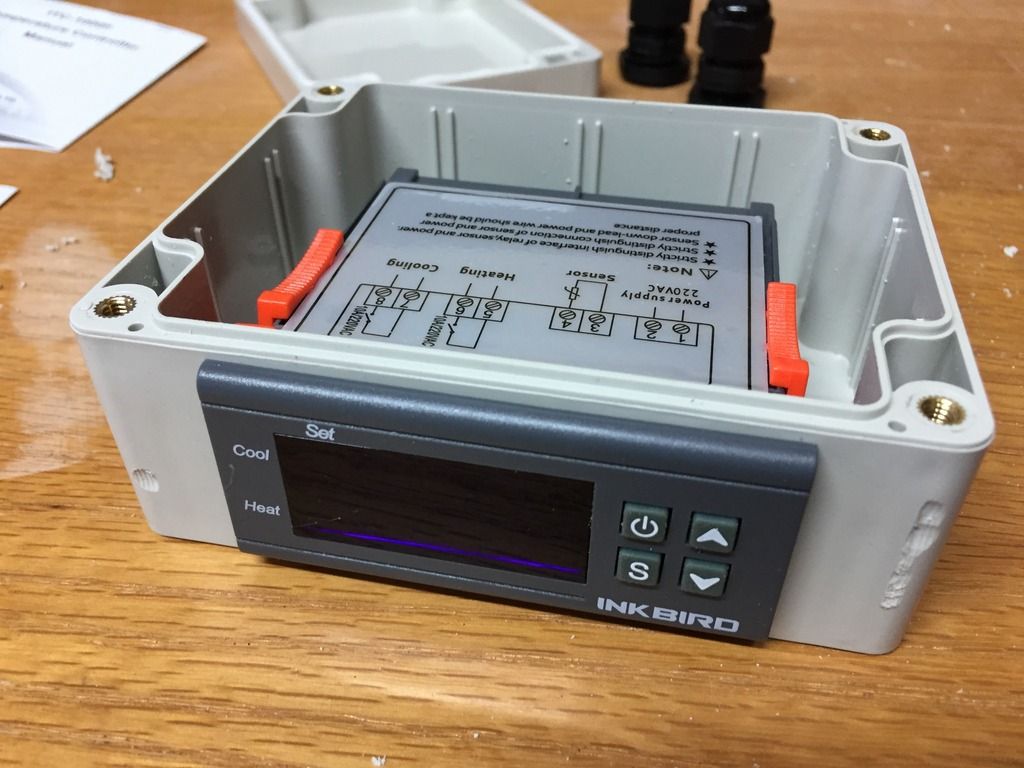

I have the Inkbird ITC 1000F as the temp controller. It comes as a basic unit and really needs housing in a box or something. So I bought a 115x90x55mm Waterproof Plastic Power Project Case to put it in. I think itââ¬â¢s a little small but will try and get it all in.

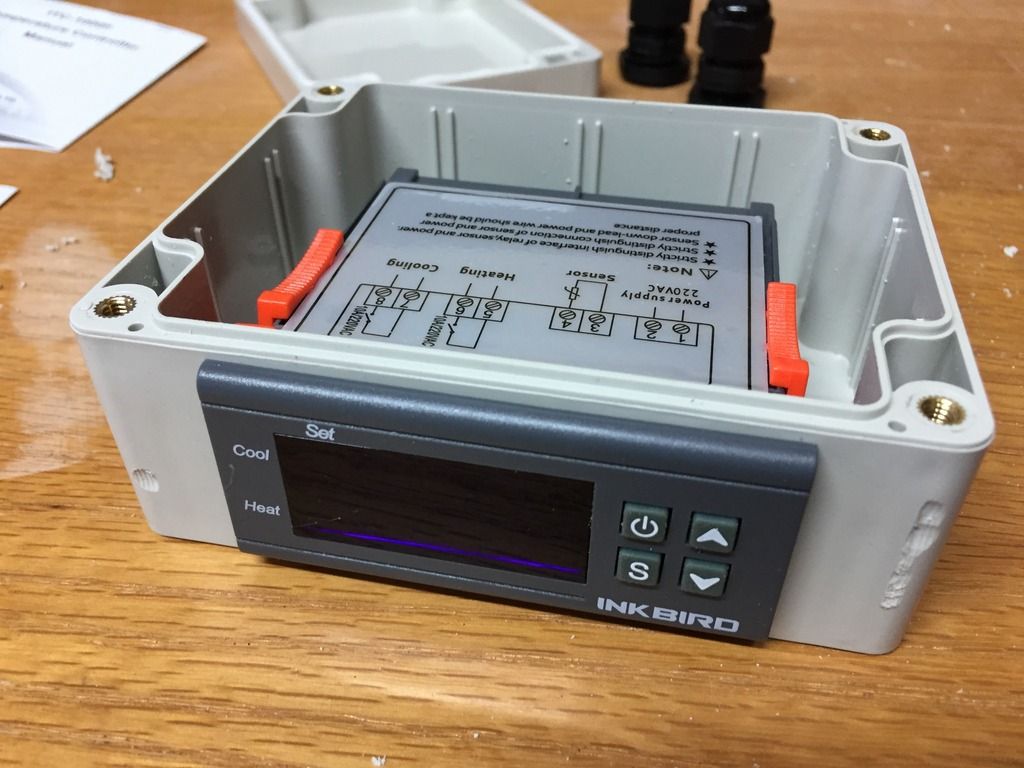

First job was to cut a hole for the Inkbird to sit in. I worked out that the orange tabs each side of the unit come off, you then slide the unit in to the case and reattach the tabs to hold it in place. Itââ¬â¢s an easy and effective way of holding the unit in the hole. There are no instructions for fitting the unit, but I guess it could be fitted in lots of different ways. So I marked out the size of the hole needed and then cut it out using a Dremel with a saw blade in it. One thing to note, donââ¬â¢t let the chuck of the Dremel come in to contact with the box when using it or it marks the edges of the box as can be seen in this pictureââ¬Â¦Ã¢â¬Â¦ dââ¬â¢oh!!!

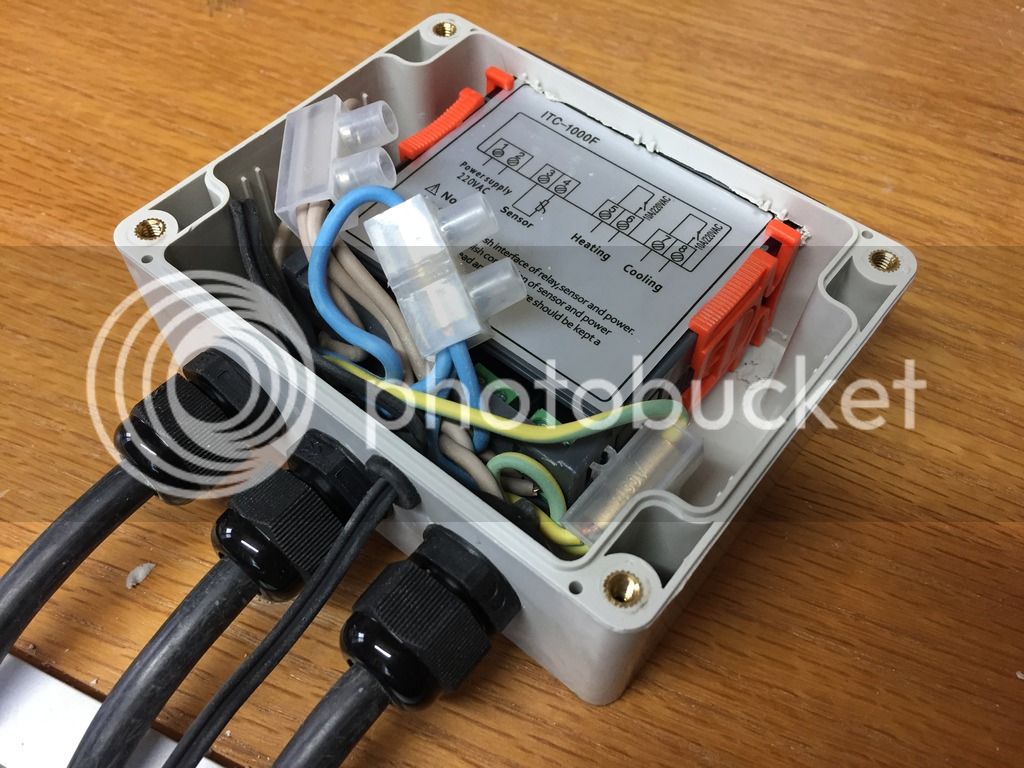

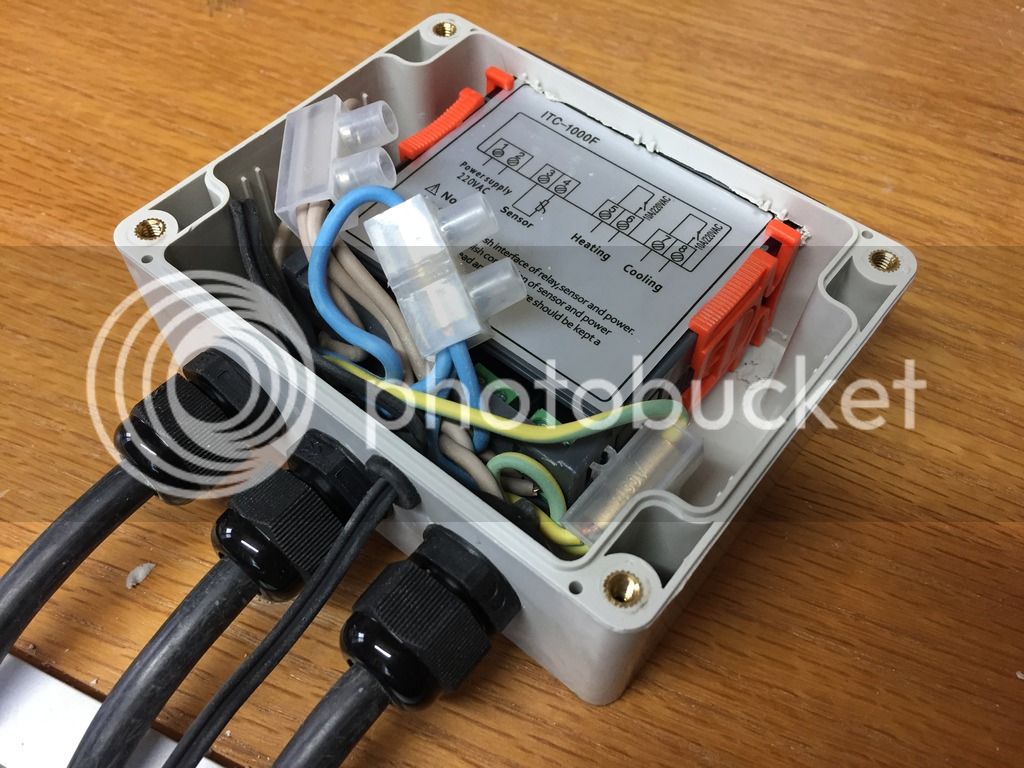

Now to start wiring it upââ¬Â¦.. I have a basic understanding of how an electrical circuit works, and I reckon this is all you need to be able to wire this unit up. I did find the wiring instructions that come with the unit ok, but I also looked on line and found some that were a bit clearer, so for a numpty like me it was good to see different wiring diagrams.

I had an old extension reel that was broken, so used the cable from that to wire up the unit. I used the choccy blocks to connect the wires together and followed the wiring diagram. I drilled out the holes in the back of the box for the main feed going in and the heating and cooling wires coming out. I also drilled a smaller hole for the sensor wire to come out. I used cable glands that I bought online for the 3 larger cables and a small grommet for the sensor cable. I think it pays to do this to prevent chaffing on the cables and it makes it look a neat job. The glands were only �ã3 for a box of 20 and you can get a box of 10 for about �ã1.50.

I then wired up the two sockets for the heater and cooler and put the lid on. I have a Dyno labeller, so stuck some labels on it to smarten it up a bit. I plugged it in and it all worked. To be honest, it was a lot easier to put together than I thought it would be. I plugged my brew fridge in to it. I have a small tube heater in the fridge too, so plugged that in as well. I then read the basic instructions that came with the Inkbird to set the temperature and also the temperature difference. It is easy to set up, just follow the instructions and scroll through the menu to set the parameters you want. I am currently using this fridge to cool my beer ready for serving. I went with 12ðc temperature and a +/- of 1ðc. I also have the compressor delay set at 3 minutes. This stops the fridge compressor turning on and off repeatedly, so prevents damage to the fridge I believe.

So far, so good. The controller is keeping the inside of the fridge at roughly 12ðc and copes well at this time of the year where daytime temps are high teens and it drops to about 8 or 9 ð overnight. I have another under counter fridge that I mainly use as a fermentation fridge, so I might look at seeing if I can fit one of these controllers directly in to the fridge and hard wire it in. This really is a cost effective way of controlling temperature for brewing. The Inkbird was �ã10.99 on Amazon, which is really cheap for what it is. The box and bits of electrical stuff was less than a tenner. The fridge was �ã20 and the tube heater was �ã15. So for about �ã55 and a couple of hours work I have an accurate temperature controlled area to put my beer, either for fermenting of serving. I can also ââ¬Ëcold crashââ¬â¢ after fermentation and I might even look at making a lager. No more worrying about what the weather is doing and it is peace of mind that my beer has a constant fermentation temp. I also really enjoyed putting this unit together. This is where I bought my Inkbird from https://www.amazon.co.uk/dp/B00IJ0F2OW/?tag=skimlinks_replacement-20

I have the Inkbird ITC 1000F as the temp controller. It comes as a basic unit and really needs housing in a box or something. So I bought a 115x90x55mm Waterproof Plastic Power Project Case to put it in. I think itââ¬â¢s a little small but will try and get it all in.

First job was to cut a hole for the Inkbird to sit in. I worked out that the orange tabs each side of the unit come off, you then slide the unit in to the case and reattach the tabs to hold it in place. Itââ¬â¢s an easy and effective way of holding the unit in the hole. There are no instructions for fitting the unit, but I guess it could be fitted in lots of different ways. So I marked out the size of the hole needed and then cut it out using a Dremel with a saw blade in it. One thing to note, donââ¬â¢t let the chuck of the Dremel come in to contact with the box when using it or it marks the edges of the box as can be seen in this pictureââ¬Â¦Ã¢â¬Â¦ dââ¬â¢oh!!!

Now to start wiring it upââ¬Â¦.. I have a basic understanding of how an electrical circuit works, and I reckon this is all you need to be able to wire this unit up. I did find the wiring instructions that come with the unit ok, but I also looked on line and found some that were a bit clearer, so for a numpty like me it was good to see different wiring diagrams.

I had an old extension reel that was broken, so used the cable from that to wire up the unit. I used the choccy blocks to connect the wires together and followed the wiring diagram. I drilled out the holes in the back of the box for the main feed going in and the heating and cooling wires coming out. I also drilled a smaller hole for the sensor wire to come out. I used cable glands that I bought online for the 3 larger cables and a small grommet for the sensor cable. I think it pays to do this to prevent chaffing on the cables and it makes it look a neat job. The glands were only �ã3 for a box of 20 and you can get a box of 10 for about �ã1.50.

I then wired up the two sockets for the heater and cooler and put the lid on. I have a Dyno labeller, so stuck some labels on it to smarten it up a bit. I plugged it in and it all worked. To be honest, it was a lot easier to put together than I thought it would be. I plugged my brew fridge in to it. I have a small tube heater in the fridge too, so plugged that in as well. I then read the basic instructions that came with the Inkbird to set the temperature and also the temperature difference. It is easy to set up, just follow the instructions and scroll through the menu to set the parameters you want. I am currently using this fridge to cool my beer ready for serving. I went with 12ðc temperature and a +/- of 1ðc. I also have the compressor delay set at 3 minutes. This stops the fridge compressor turning on and off repeatedly, so prevents damage to the fridge I believe.

So far, so good. The controller is keeping the inside of the fridge at roughly 12ðc and copes well at this time of the year where daytime temps are high teens and it drops to about 8 or 9 ð overnight. I have another under counter fridge that I mainly use as a fermentation fridge, so I might look at seeing if I can fit one of these controllers directly in to the fridge and hard wire it in. This really is a cost effective way of controlling temperature for brewing. The Inkbird was �ã10.99 on Amazon, which is really cheap for what it is. The box and bits of electrical stuff was less than a tenner. The fridge was �ã20 and the tube heater was �ã15. So for about �ã55 and a couple of hours work I have an accurate temperature controlled area to put my beer, either for fermenting of serving. I can also ââ¬Ëcold crashââ¬â¢ after fermentation and I might even look at making a lager. No more worrying about what the weather is doing and it is peace of mind that my beer has a constant fermentation temp. I also really enjoyed putting this unit together. This is where I bought my Inkbird from https://www.amazon.co.uk/dp/B00IJ0F2OW/?tag=skimlinks_replacement-20

Last edited by a moderator:

![BREWING THERMOMETER STICKERS ACCURATELY MONITOR FERMENTING BEER & WINE LIQUID TEMPERATURES 5PCS HOME BREW SPIRITS WINE LCD ADHESIVE [US]](https://m.media-amazon.com/images/I/311DDjo2X3L._SL500_.jpg)